Temperature Control in Photolithography

In photolithography, high-precision temperature control enables repeatable pattern transfer and improves yield. This article explains what photolithography is, why thermal stability matters, which tool elements need precise temperature, common control methods, how semiconductor chillers fit into the system.

What is Photolithography?

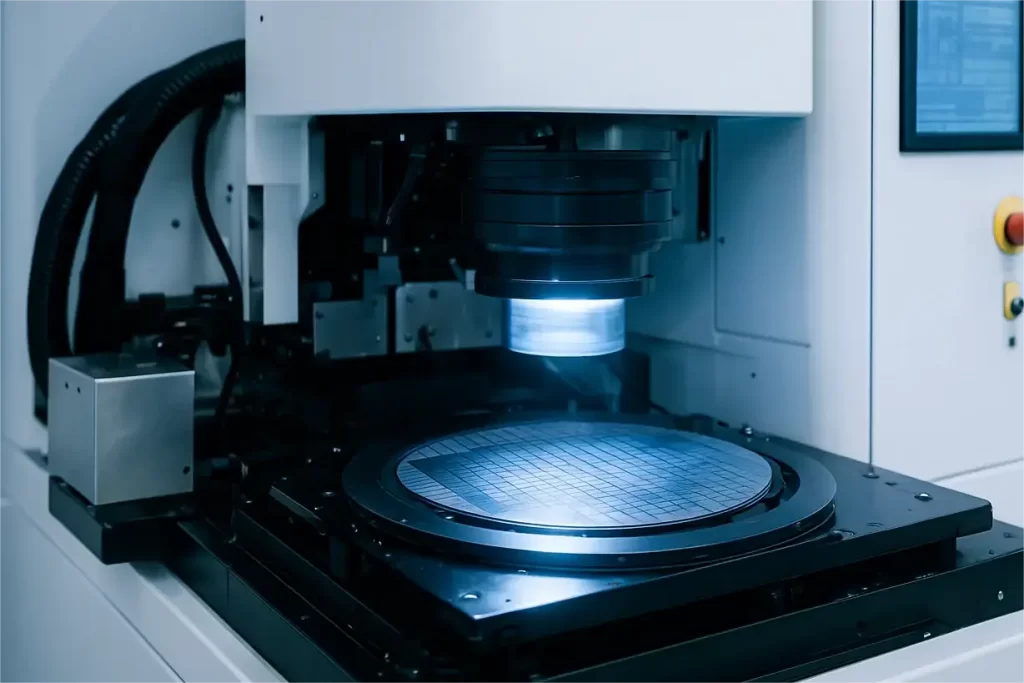

Photolithography is the process of transferring circuit patterns onto a silicon wafer using light, photoresist, and precision optics.

It combines coating, exposure, development, and baking steps. Photolithography operates at micro and nanoscale dimensions. The process starts with wafer cleaning and resist coating, proceeds to exposure through a photomask or reticle, and ends with development and post-exposure bake.

Why Temperature Control Matters in Photolithography?

Temperature Control in Photolithography refer to the absolute temperature and temperature uniformity across components and wafers.

Thermal conditions influence resist chemistry, optical focus, and mechanical alignment. Slight temperature increases change resist reaction rates and diffusion during baking, which shifts critical dimensions.

Optics are also temperature sensitive, since variations in lens temperature or refractive index push the focal plane out of position. Mechanical components such as the wafer stage expand or contract with heat, introducing small alignment errors that accumulate across layers.

This small deviations translate into critical dimension errors, overlay shifts, and increased scrap, so thermal stability is essential for consistent device performance and high yield.

What are the Key Temperature-Controlled Components?

The main lithography components requiring temperature control are the wafer stage, projection optics, exposure source, resist coating and bake modules, and coolant loops.

1.Wafer stage

The wafer stage must remain uniform in temperature so position sensors and metrology corrections remain valid.

2.Projection optics and lenses

Optical elements change refractive index and physical dimensions with temperature. Stable cooling or localized heating prevents focus shift and aberration.

3.Exposure source (lasers or lamps)

High-intensity light sources create rapid heat swings. Source cooling preserves beam profile and output stability, which directly affects exposure dose.

4.Coating, bake, and development modules

Soft-bake and post-exposure bake recipes require exact plate temperatures to control resist flow and crosslinking. Developer temperature affects contrast and critical dimension control.

5.Internal coolant loops and sensors

Closed-loop fluid circuits feed optics, stages, and electronics. Sensors along these loops provide feedback for PID control and alarm conditions.

What are the Methods Used for Temperature Control in Photolithography?

Photolithography combines room-level environmental control, tool-level thermal modules, and precision liquid cooling. Below are the primary methods and where it is typically applied.

1.Precision chillers and recirculating fluid loops

Supply stable coolant to optics, stages, and light sources, maintaining setpoint under varying heat load.

2.Environmental control systems

Cleanroom precision AC keeps ambient temperature and relative humidity within narrow limits, reducing external thermal influence.

3.Active heating plates and bake units

Provide controlled thermal ramps for resist soft-bake and post-exposure bake, controlled by PID loops.

4.Localized thermal isolation and enclosures

Minimize cross-talk from adjacent modules and protect sensitive optics from airborne thermal perturbations.

5.Real-time sensor networks and closed-loop control

Distributed temperature sensors feed controllers that adjust flow rate, heater power, or valve position to maintain uniformity.

In practice, fabs use combinations of these approaches. For instance, a tool may rely on cleanroom stability for baseline control, while chillers and localized heaters handle dynamic loads during exposures.

How Semiconductor Chillers Support Photolithography?

Halbleiter-Kühlgeräte provide the high-precision liquid temperature control needed to stabilize optics, stages, and sources. They remove heat reliably, minimize temperature noise, and support rapid response to transient heat loads.

1.Tight temperature stability

Chillers can hold fluid to within ±0.05°C, or better for demanding processes, which reduces thermal drift across wafers.

2.Fast response to heat load changes

Variable-speed pumps and advanced control loops allow quick compensation when exposure energy spikes.

3.Fluid compatibility and cleanliness

Units that handle DI water or controlled coolant mixtures avoid corrosion and particle contamination that would harm optics.

4.Monitoring, alarms, and safety

Built-in flow sensors, leak detection, and remote alerts prevent silent failures that would otherwise cause tool excursions.

5.Redundancy and reliability

Many fabs configure chillers with redundancy to avoid unplanned downtime during continuous production.

Choosing the Right Temperature Control System for Lithography

Selecting a system requires balancing precision, capacity, fluid compatibility, response time, and supportability. Semiconductor chillers and precision air conditioners are often essential equipment in semiconductor factories.

If you are looking for a reliable temperature control solution for photolithography processes, LNEYA is happy to provide you with free technical support.

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant