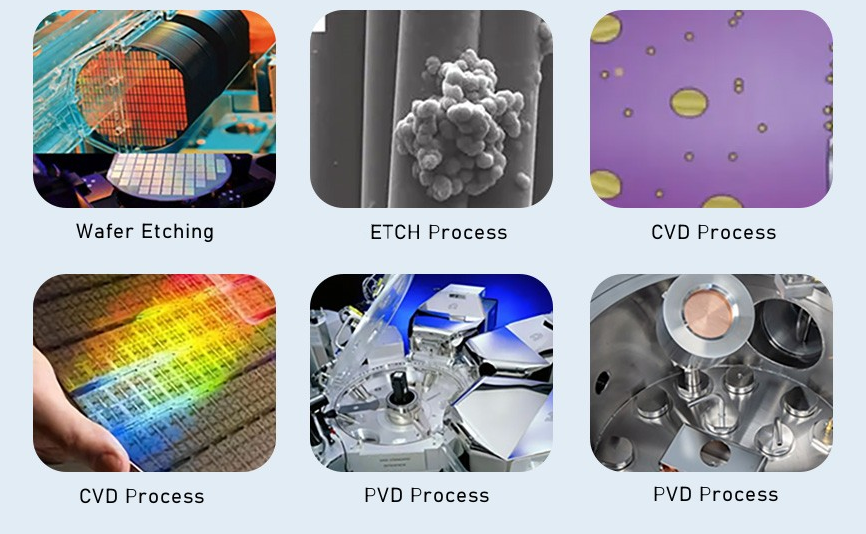

Wafer Dünnschichtabscheidung Temperaturregelung Ausrüstung Kühler Verwendung Umwelt

The wafer thin film deposition temperature control equipment chiller is an equipment used for cooling and heating temperature control testing in the component semiconductor manufacturing industry. So what should you pay attention to when using the environment?

1.Power distribution requirements for chiller unit of wafer thin film deposition temperature control equipment:

- Main power supply voltage: Within the rated voltage requirements, when the main power supply voltage fluctuation exceeds the specified range, the component high and low temperature testing machine chiller is not allowed to be started, otherwise it will be regarded as improper operation, and the damage caused thereby is not within the scope of our company’s maintenance. The water flow switch, water pump, cooling tower motor and other interlocking circuits of the water system can be correctly connected to the unit control circuit when necessary.

- The chiller unit of the wafer thin film deposition temperature control equipment is equipped with various measures and control circuits such as current overload protection, high and low pressure protection at the compressor exhaust end, motor coil overheating protection, anti-icing protection, cooling water flow chain protection, etc. The control circuit of the chiller group of LNEYA’s wafer thin film deposition temperature control equipment has been installed and debugged in the factory. Do not make any unauthorized changes. If you need to make any changes, please contact the technical department.

2.The following matters should be noted during installation:

- When lifting and installing the wafer thin film deposition temperature control equipment chiller, be careful not to damage the unit, and arrange the surrounding space reasonably to facilitate the maintenance of the wafer thin film deposition temperature control equipment chiller.

- According to the requirements for piping system design and construction and installation, the frozen water and cooling water system should be reasonably designed and installed to give full play to the chiller performance of the wafer thin film deposition temperature control equipment. It should be placed horizontally and installed in a ventilated position. For unit piping, please refer to the LNEYA product manual for recommended installation and construction.

When the environment around the water source and radiator tower is harsh, the chilled water and cooling water circuits must be installed with Y-type filters and cleaned regularly. An automatic exhaust valve must be installed at the top of the closed chilled water system, and a

7 * 24 kostenlose Beratung und umfassende Lösungen anbieten

E-Mail: sales@cnzlj.com

WhatsApp: 086 13912479193

Verwandte Empfehlungen

-

Precautions for using the wafer testing temperature control system

1447Precautions for using the wafer testing temperature control system

Details anzeigen -

LTS -80℃~80℃

2109It is widely used in the semiconductor manufacturing process to control the temperature of the reaction chamber, the temperature of the heat sink, and the temperature control of the non-flammable fluid of the heat transfer me...

Details anzeigen -

TES -45℃~250℃

2893Temperature control range:-45°C ~ 250°C ;Power range:2.5kW~25kW;Temperature control accuracy:±0.3°C Chip-Specific High and Low Temperature Test Boxes In the manufacture of semiconductor electronic components for harsh env...

Details anzeigen -

LTS -20℃~80℃

2138Es wird häufig in der Halbleiterherstellung verwendet, um die Temperatur der Reaktionskammer, die Temperatur der Wärmesenke und die Temperatur der nicht brennbaren Flüssigkeit des Wärmeübertragungsmediums zu kontrollieren...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant

Zur Konsultation einreichen

Wir werden Ihnen innerhalb von 24 Stunden antworten