Halbleiterkühlung Temperaturregelung Tischkühler Betriebsanleitung

The power supply switching of the control system of the transformer cooling system of the semiconductor refrigeration temperature control station uses the imported dual power automatic switching device. Its main function is automatic switching between the active and standby working power sources. When the common power failure occurs, it automatically switches to the standby power supply. When both power supplies are normal, the common power supply works and the standby power supply is in standby state. The semiconductor refrigeration temperature control station programmable controller (PLC) is the control center of the execution part of the strong oil air cooler control device. It receives various status signals from the transformer to control the execution part.

When the transformer of the semiconductor refrigeration temperature control console is put into operation, a group of coolers will be put into operation, that is, the working group cooler is operated. The auxiliary cooler is controlled according to the oil surface temperature of the transformer, the winding temperature, the load signal, etc., and the auxiliary cooler can be activated as follows. The cooling method of the semiconductor refrigeration temperature control transformer is forced oil circulation air cooling, and at least one group of coolers should be operated after the transformer is put into operation. The control box of the semiconductor refrigeration temperature control station is controlled by intelligent equipment, and the cooling device for controlling the transformer is mainly controlled by a main switch such as a change switch on the control panel.

The structure and operation description of the semiconductor refrigeration temperature control station are as shown above. When the user operates the semiconductor refrigeration temperature control station, the operating efficiency of each component is ensured as much as possible, so that the overall operating efficiency of the semiconductor refrigeration temperature control station can be improved.

Verwandte Empfehlungen

-

Is it right to extend battery life by lowering the ambient temperature?

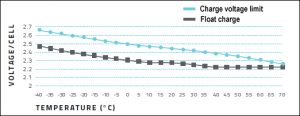

1507The battery can work in a wide temperature range, but this does not allow the battery to be charged under high temperature conditions. The charging process is more delicate than the discharging process, and extreme care must be taken. Extreme cold...

Details anzeigen -

Core Maintenance Points of Ten High and Low Temperature Test Chamber Manufacturers

1557According to many years’ production experience of high and low temperature test chamber in Wuxi Guanya, it is found that many users are not very familiar with the maintenance of high and low temperature test chamber. As one of the top ten manufact...

Details anzeigen -

Battery module test equipment selection error description

1614Many battery module companies have certain misunderstandings about LNEYA's battery module test equipment. There are some errors in selecting the battery module test equipment model, so try to select the battery module test equipment. Avoid some mi...

Details anzeigen -

Was sind die Merkmale des Reaktorheizsystems?

1253Wuxi Guanya LNEYA Reaktorheizsystem Der Flüssigkeitsumlauf des gesamten Systems ist geschlossen, das System hat ein Ausdehnungsgefäß, das Ausdehnungsgefäß und der Flüssigkeitsumlauf sind adiabatisch, nehmen nicht am Flüssigkeitsumlauf teil, nur die...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant