Normal & Low Temperature Chillers -40℃~160℃

Control Temperature & Flow Systems

For Vehicle Components Testing,Hydrogen energy industry

Das Temperatur- und Durchflusssystem unterstützt ein bis mehrere Systeme, d. h. ein Kühl- und Heizungs-Temperatursteuerungs-Host kann 2-6 verschiedene Prüfstände oder Temperatursteuerungs-Durchflussgeräte steuern. Unterstützt zwei "one to many"-Modi, d.h. Temperatur/Durchfluss/Druck können unabhängig voneinander gesteuert werden (T-Serie), und die Temperatur ist über mehrere Gruppen hinweg konsistent, und Durchfluss/Druck wird unabhängig voneinander gesteuert (S-Serie).(LNEYAs Kühler unterstützt sowohl Innen- als auch Außenoptionen.)

The automotive industry must ensure that its products operate over this wide temperature range and do not fail or material fatigue under rapid temperature changes.

Therefore, material and component testing, including temperature simulation, is very important and indispensable for the automotive industry, including all suppliers.

On the test benches in the automotive industry, highly dynamic temperature control systems are used for material and component testing, which can achieve precise regulation and rapid temperature changes. Only precise temperature management can provide reliable and repeatable results. The temperature control system provides a constant temperature or a complex temperature curve to the test bench directly or indirectly through a liquid medium. In addition to the temperature of the medium, temperature control systems also allow precise control of flow rates and operating pressures. Temperature control systems are used primarily in two ways: They simulate external ambient conditions in climate chambers or replace internal systems, such as the cooling circuit of an engine. The latter allows realistic conditions to be created on test benches, where test specimens are supplied with coolant according to operational requirements, such as in a vehicle.

Wir beliefern unsere Kunden aus der Automobilindustrie mit leistungsfähigen Geräten. Diese decken nicht nur den gesamten Temperaturbereich von -40°C bis +160°C und die auf Prüfständen erforderlichen schnellen Temperaturwechsel dynamisch ab.

KRY series advantages

● Efficient production stability and repeatability results;

Einsatz von Plattenwärmetauschern und Rohrleitungsheizungen zur Verbesserung der Kühl- und Heizleistung;

● Very wide temperature range, no need to replace liquid medium;

Vollständig geschlossenes System, das die Lebensdauer von wärmeleitenden Flüssigkeiten verlängert;

● Adopting magnetic drive pump, there is no problem of shaft seal leakage

LOW TEMPERATURE SERIES

KRY -20℃~+100℃

| Modell |

KRY-255

KRY-255W |

KRY-275

KRY-275W |

KRY-2A10

KRY-2A10W |

KRY-2A15

KRY-2A15W |

KRY-2A25

KRY-2A25W |

KRY-2A38W |

| Temperaturbereich |

-20℃~+100℃ |

| Temperaturregelgenauigkeit |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

| Rückmeldung zur Temperatur |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

| Temp-Anzeige |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

| Ausgabe der Durchflussmenge |

1~15 L/min |

1~25 L/min |

1~30 L/min |

1~40 L/min |

1~40 L/min |

1~40 L/min |

| Genauigkeit des Durchflusses |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

| Heizleistung |

5,5 kW |

7,5 kW |

10kW |

15kW |

25kW |

38kW |

| Kühlleistung |

100℃ |

5,5 kW |

7,5 kW |

10kW |

15kW |

25kW |

38kW |

| 20℃ |

5,5 kW |

7,5 kW |

10kW |

15kW |

25kW |

38kW |

| 0℃ |

5,5 kW |

7,5 kW |

10kW |

15kW |

25kW |

38kW |

| -15℃ |

2,8 kW |

3,8 kW |

4,6 kW |

7kW |

12kW |

16kW |

| Größe der Verbindung |

G3/4 |

G3/4 |

G3/4 |

G3/4 |

G3/4 |

G3/4 |

| Water-cooled type W at 25℃ |

1900L/H

ZG3/4 |

2500L/H

ZG3/4 |

3000L/H

ZG1 |

4000L/H

ZG1 |

6000L/H

DN32 |

9000L/H

DN40 |

| Leistung 380V50HZ |

11kW |

14kW |

19kW |

23kW |

31kW |

45kW |

| Abmessungen(cm) |

55*100*175 |

55*100*175 |

70*100*175 |

80*120*185 |

100*150*185 |

100*150*185 |

| Gewicht |

230kg |

250kg |

300kg |

320kg |

570kg |

830kg |

| Optional |

Extend to -40~+135℃ |

KRY -40℃~+100℃

| Modell |

KRY-455

KRY-455W |

KRY-475

KRY-475W |

KRY-4A10

KRY-4A10W |

KRY-4A15

KRY-4A15W |

KRY-4A25

KRY-4A25W |

KRY-4A38W |

KRY-4A60W |

| Temperaturbereich |

-40℃~+100℃ |

-40℃~+100℃ |

-40℃~+100℃ |

-40℃~+100℃ |

-40℃~+100℃ |

-40℃~+100℃ |

-40℃~+100℃ |

| Temperaturregelgenauigkeit |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

| Rückmeldung zur Temperatur |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

| Temp-Anzeige |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

| Ausgabe der Durchflussmenge |

1~25 L/min |

1~25 L/min |

1~25 L/min |

1~40 L/min |

1~40 L/min |

1~40 L/min |

1~40 L/min |

| Genauigkeit des Durchflusses |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

| Heizleistung |

5,5 kW |

7,5 kW |

10kW |

15kW |

25kW |

38kW |

60kW |

| Kühlleistung |

100℃ |

5,5 kW |

7,5 kW |

10kW |

15kW |

25kW |

38kW |

60kW |

| 20℃ |

5,5 kW |

7,5 kW |

10kW |

15kW |

25kW |

38kW |

60kW |

| 0℃ |

5,5 kW |

7,5 kW |

10kW |

15kW |

25kW |

38kW |

60kW |

| -20℃ |

2,8 kW |

4,5 kW |

6kW |

10kW |

16kW |

25kW |

35kW |

| -35℃ |

1,2 kW |

1,8 kW |

2,5 kW |

4kW |

6,5 kW |

10kW |

15kW |

| Größe der Verbindung |

ZG3/4 |

ZG3/4 |

ZG3/4 |

ZG3/4 |

ZG3/4 |

ZG3/4 |

ZG3/4 |

| Water-cooled type Wat25度 |

1900L/H

ZG3/4 |

2500L/H

ZG3/4 |

3000L/H

ZG1 |

4000L/H

ZG1 |

6000L/H

DN32 |

9000L/H

DN40 |

15000L/H

DN50 |

| Leistung 380V50HZ |

10kW |

14kW |

17kW |

25kW |

38kW |

58kW |

84kW |

| Abmessungen(cm) |

55*100*175 |

55*100*175 |

70*100*175 |

80*120*185 |

100*150*185 |

100*150*185 |

200*145*205 |

| Gewicht |

250kg |

280kg |

320kg |

360kg |

620kg |

890kg |

1300KG |

| Optional |

Extend to -40~+135℃ |

KRY -40℃~+100℃ 2T

| Modell |

KRY-475/2T

KRY-475W/2T |

KRY-4A15W/2T |

KRY-4A25W/2T |

KRY-4A38W/2T |

KRY-4A60W/2T |

| Temperaturbereich |

-40℃~+100℃ |

| Temperaturregelgenauigkeit |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

| Rückmeldung zur Temperatur |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

| Temp-Anzeige |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

| Genauigkeit der Durchflusskontrolle/Gruppe |

1~25 L/min |

1~40 L/min |

1~40 L/min |

1~40 L/min |

1~40 L/min |

| Durchflussgenauigkeit/Gruppe |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

| Anzahl der Fluidausgangsgruppen |

2 Gruppen |

2 Gruppen |

2 Gruppen |

2 Gruppen |

2 Gruppen |

| Druckregelung/Gruppe |

0.2bar~2.5bar |

0.2bar~2.5bar |

0.2bar~2.5bar |

0.2bar~2.5bar |

0.2bar~2.5bar |

| Heizleistung |

7.5kW*2 |

10kW*2 |

15kW*2 |

25kW*2 |

38kW*2 |

| Kühlleistung |

100℃ |

7.5kW*2 |

15kW*2 |

25kW*2 |

38kW*2 |

60kW*2 |

| 20℃ |

7.5kW*2 |

15kW*2 |

25kW*2 |

38kW*2 |

60kW*2 |

| 0℃ |

7.5kW*2 |

15kW*2 |

25kW*2 |

38kW*2 |

60kW*2 |

| -20℃ |

4.5kW*2 |

8.5kW*2 |

14kW*2 |

22kW*2 |

35kW*2 |

| -35℃ |

1.8kW*2 |

4kW*2 |

6.5kW*2 |

10kW*2 |

15kW*2 |

| Water-cooled type Wat 20度 |

4000L/H

ZG1 |

8000L/H

DN32 |

12000L/H

DN40 |

20000L/H

DN50 |

30000L/H

DN65 |

| Abmessungen(cm) |

28kW |

45kW |

70kW |

108kW |

158kW |

| Wassergekühlt cm |

80*100*185 |

100*150*185 |

200*145*205 |

200*145*205 |

250*145*225 |

| Gewicht |

660KG |

850KG |

1350KG |

1800KG |

2600KG |

| Optional |

Extend to -40~+135℃ |

KRY -20℃~+100℃ 6S

| Modell |

KRY-2A25W/6S |

KRY-2A38W/6S |

KRY-2A60W/6S |

| Temperaturbereich |

-20℃~+100℃ |

| Temperaturregelgenauigkeit |

±0.3℃ |

±0.3℃ |

±0.3℃ |

| Rückmeldung zur Temperatur |

Pt100 |

Pt100 |

Pt100 |

| Temp-Anzeige |

0.01k |

0.01k |

0.01k |

| Genauigkeit der Durchflusskontrolle/Gruppe |

1~25 L/min |

1~25 L/min |

1~40 L/min |

| Durchflussgenauigkeit/Gruppe |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

| Anzahl der Fluidausgangsgruppen |

6 Gruppen |

6 Gruppen |

6 Gruppen |

| Druckregelung/Gruppe |

0.2bar~2.5bar |

0.2bar~2.5bar |

0.2bar~2.5bar |

| Heizleistung |

15kW |

25kW |

38kW |

| Kühlleistung |

100℃ |

25kW |

38kW |

60kW |

| 20℃ |

25kW |

38kW |

60kW |

| 0℃ |

25kW |

38kW |

60kW |

| -15℃ |

10kW |

15kW |

24kW |

| Water-cooled type Wat 20度 |

8000L/H

DN40 |

12000L/H

DN50 |

20000L/H

DN65 |

| Leistung 380V50HZ |

36kW |

51kW |

75kW |

| Wassergekühlt cm |

200*145*205 |

200*145*205 |

200*145*205 |

| Gewicht |

900kg |

1100kg |

1750kg |

KRY -40℃~+100℃ 6S

| Modell |

KRY-4A25W/6S |

KRY-4A38W/6S |

KRY-4A60W/6S |

| Temperaturbereich |

-40℃~+100℃ |

| Temperaturregelgenauigkeit |

±0.3℃ |

±0.3℃ |

±0.3℃ |

| Rückmeldung zur Temperatur |

Pt100 |

Pt100 |

Pt100 |

| Temp-Anzeige |

0.01k |

0.01k |

0.01k |

| Genauigkeit der Durchflusskontrolle/Gruppe |

1~25 L/min |

1~25 L/min |

1~40 L/min |

| Durchflussgenauigkeit/Gruppe |

±0.2 L/min |

±0.2 L/min |

±0.2 L/min |

| Anzahl der Fluidausgangsgruppen |

6 Gruppen |

6 Gruppen |

6 Gruppen |

| Druckregelung/Gruppe |

0.2bar~2.5bar |

0.2bar~2.5bar |

0.2bar~2.5bar |

| Heizleistung |

15kW |

25kW |

38kW |

| Kühlleistung |

100℃ |

25kW |

38kW |

60kW |

| 20℃ |

25kW |

38kW |

60kW |

| 0℃ |

25kW |

38kW |

60kW |

| -20℃ |

14kW |

22kW |

35kW |

| -35℃ |

5kW |

8kW |

13kW |

| Water-cooled type Wat 20度 |

8000L/H

DN40 |

12000L/H

DN50 |

18000L/H

DN65 |

| Leistung 380V50HZ |

38kW |

55kW |

82kW |

| Abmessungen(cm) |

200*145*205 |

200*145*205 |

200*145*205 |

| Gewicht |

900kg |

1200kg |

1950kg |

| Optional |

Extend to -40~+135℃ |

NORMAL TEMPERATURE SERIES

KRY 0℃~+100℃

| Modell |

KRY-25 |

KRY-55 |

KRY-75 |

KRY-A10 |

KRY-A15

KRY-A15W |

KRY-A25

KRY-A25W |

KRY-A38W |

KRY-A60W |

| Temperaturbereich |

0℃~+100℃ |

| Temperaturregelgenauigkeit |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

| Rückmeldung zur Temperatur |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

| Temp-Anzeige |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

| Ausgabe der Durchflussmenge |

2~20 L/min |

2~25 L/min |

2~25 L/min |

2~25 L/min |

2~25 L/min |

2~25 L/min |

5~50 L/min |

5~50 L/min |

| Genauigkeit des Durchflusses |

±0.2 L/min |

| Heizleistung |

2,5 kW |

5,5 kW |

7,5 kW |

10kW |

15kW |

15kW |

25kW |

38kW |

| Kühlleistung |

100℃ |

2,5 kW |

5,5 kW |

7,5 kW |

10kW |

15kW |

25kW |

38kW |

60kW |

| 20℃ |

2,5 kW |

5,5 kW |

7,5 kW |

10kW |

15kW |

25kW |

38kW |

60kW |

| 5℃ |

1,8 kW |

3,8 kW |

5,2 kW |

7kW |

11kW |

18kW |

27kW |

42kW |

| Größe der Verbindung |

G3/4 |

G3/4 |

G3/4 |

G3/4 |

G3/4 |

G3/4 |

G3/4 |

G3/4 |

| Water-cooled type Wat25度 |

|

|

|

|

3200L/H

ZG1 |

6000L/H

G1 1/4 |

9000L/H

DN40 |

15000L/H

DN50 |

| Leistung 380V50HZ |

4.5kW220V |

8,5 kW |

11,5 kW |

16kW |

18kW |

28kW |

40kW |

61kW |

| Abmessungen(cm) |

50*85*145 |

55*100*175 |

55*100*175 |

70*100*175 |

80*120*185 |

100*150*185 |

100*150*185 |

100*150*185 |

| Gewicht |

220kg |

250kg |

280kg |

320kg |

360kg |

620kg |

890kg |

1300KG |

KRY 0℃~+100℃ 2T

| Modell |

KRY-25/2T |

KRY-55/2T |

KRY-75/2T |

KRY-A10/2T |

KRY-A15W//2T |

KRY-A25W/2T |

KRY-A38W/2T |

KRY-A60W/2T |

| Temperaturbereich |

0℃~+100℃ |

| Temperaturregelgenauigkeit |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

±0.3℃ |

| Rückmeldung zur Temperatur |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

Pt100 |

| Temp-Anzeige |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

0.01k |

| Ausgabe der Durchflussmenge |

2~20 L/min |

2~25 L/min |

2~25 L/min |

2~25 L/min |

2~25 L/min |

2~25 L/min |

5~50 L/min |

5~50 L/min |

| Genauigkeit des Durchflusses |

±0.2 L/min |

| Heizleistung |

2.5kW*2 |

5.5kW*2 |

7.5kW*2 |

10kW*2 |

15kW*2 |

15kW*2 |

25kW*2 |

38kW*2 |

| Kühlleistung |

100℃ |

2.5kW*2 |

5.5kW*2 |

7.5kW*2 |

10kW*2 |

15kW*2 |

25kW*2 |

38kW*2 |

60kW*2 |

| 20℃ |

2.5kW*2 |

5.5kW*2 |

7.5kW*2 |

10kW*2 |

15kW*2 |

25kW*2 |

38kW*2 |

60kW*2 |

| 5℃ |

1.8kW*2 |

3.8kW*2 |

5.2kW*2 |

7kW*2 |

11kW*2 |

18kW*2 |

27kW*2 |

42kW*2 |

| Größe der Verbindung |

ZG3/4 |

ZG3/4 |

ZG3/4 |

ZG3/4 |

ZG3/4 |

ZG3/4 |

ZG3/4 |

ZG3/4 |

| Water-cooled type Wat25度 |

|

|

|

|

5600L/H

DN32 |

10000L/H

DN40 |

17000L/H

DN50 |

24000L/H

DN65 |

| Leistung 380V50HZ |

9kW |

19kW |

23kW |

29kW |

34kW |

52kW |

80kW |

120kW |

| Abmessungen(cm) |

55*100*175 |

70*100*175 |

80*120*185 |

100*150*185 |

100*150*185 |

200*145*205 |

200*145*205 |

250*145*225 |

| Gewicht |

260KG |

320KG |

400KG |

580KG |

750KG |

1250KG |

1600KG |

2400KG |

KRY 0℃~+100℃ 6S

| Modell |

KRY-A25W/6S |

KRY-A38W/6S |

KRY-A60W/6S |

| Temperaturbereich |

0℃~+100℃ |

| Temperaturregelgenauigkeit |

±0.3℃ |

±0.3℃ |

±0.3℃ |

| Rückmeldung zur Temperatur |

Pt100 |

Pt100 |

Pt100 |

| Temp-Anzeige |

0.01k |

0.01k |

0.01k |

| Genauigkeit der Durchflusskontrolle/Gruppe |

2~25 L/min |

2~25 L/min |

2~25 L/min |

| Durchflussgenauigkeit/Gruppe |

±0.2L/min |

| Anzahl der Fluidausgangsgruppen |

6 Gruppen |

6 Gruppen |

6 Gruppen |

| Druckregelung/Gruppe |

0.2bar~2.5bar |

0.2bar~2.5bar |

0.2bar~2.5bar |

| Heizleistung |

15kW |

25kW |

38kW |

| Kühlleistung |

100℃ |

25kW |

38kW |

60kW |

| 20℃ |

25kW |

38kW |

60kW |

| 5℃ |

18kW |

27kW |

42kW |

| Water-cooled type Wat 20度 |

6000L/H

DN32 |

9000L/H

DN40 |

15000L/H

DN50 |

| Leistung 380V50HZ |

38kW |

55kW |

82kW |

| Abmessungen(cm) |

200*145*205 |

200*145*205 |

200*145*205 |

| Gewicht |

900kg |

1200kg |

1950kg |

Frequency Conversion Series

KRYZ -40℃~+100℃

| Modell |

KRYZ-475

KRYZ-475W |

KRYZ-4A15W |

KRYZ-4A25W |

| Temperaturbereich |

-40℃~+100℃ |

-40℃~+100℃ |

-40℃~+100℃ |

| Temperaturregelgenauigkeit |

±0.1℃ |

±0.1℃ |

±0.1℃ |

| Rückmeldung zur Temperatur |

Pt100 |

Pt100 |

Pt100 |

| Temp-Anzeige |

0.01k |

0.01k |

0.01k |

| Ausgabe der Durchflussmenge |

1~25 L/min |

1~25 L/min |

1~25 L/min |

| Genauigkeit des Durchflusses |

±0.1 L/min |

±0.1 L/min |

±0.1 L/min |

| Heizleistung |

7,5 kW |

15kW |

25kW |

Kühlung

Kapazität |

100℃ |

7,5 kW |

15kW |

25kW |

| 20℃ |

7,5 kW |

15kW |

25kW |

| 0℃ |

7,5 kW |

15kW |

25kW |

| -20℃ |

4,5 kW |

10kW |

16kW |

| -35℃ |

1,8 kW |

4kW |

6,5 kW |

| Größe der Verbindung |

G3/4 |

G3/4 |

G3/4 |

| Water-cooled At20℃ |

2500L/H

ZG3/4 |

4000L/H

ZG1 |

6000L/H

DN32 |

| Leistung 380V50HZ |

14kW |

25kW |

38kW |

| Abmessungen(cm) |

55*85*175 |

70*100*175 |

80*120*185 |

| Gewicht |

280kg |

360kg |

620kg |

| Optional |

Extended to -40 ℃~+135 ℃ |

KRYZ -40℃~+100℃ 2T

| Modell |

KRYZ-475W/2T |

KRYZ-4A15W/2T |

KRYZ-4A25W/2T |

| Temperaturbereich |

-40℃~+100℃ |

| Temperaturregelgenauigkeit |

±0.1℃ |

±0.1℃ |

±0.1℃ |

| Rückmeldung zur Temperatur |

Pt100 |

Pt100 |

Pt100 |

| Temp-Anzeige |

0.01k |

0.01k |

0.01k |

| Ausgabe der Durchflussmenge |

1~25 L/min |

1~25 L/min |

1~25 L/min |

| Genauigkeit der Durchflusskontrolle/Gruppe |

±0.1 L/min |

±0.1 L/min |

±0.1 L/min |

| Anzahl der Fluidausgangsgruppen |

2 Gruppen |

2 Gruppen |

2 Gruppen |

| Druckregelung/Gruppe |

0.2bar~2.5bar |

0.2bar~2.5bar |

0.2bar~2.5bar |

| Heizleistung |

7.5kW*2 |

10kW*2 |

15kW*2 |

Kühlung

Kapazität |

100℃ |

7.5kW*2 |

15kW*2 |

25kW*2 |

| 20℃ |

7.5kW*2 |

15kW*2 |

25kW*2 |

| 0℃ |

7.5kW*2 |

15kW*2 |

25kW*2 |

| -20℃ |

4.5kW*2 |

8.5kW*2 |

14kW*2 |

| -35℃ |

1.8kW*2 |

4kW*2 |

6.5kW*2 |

| Water-cooled At20℃ |

4000L/H

ZG1 |

8000L/H

DN32 |

12000L/H

DN40 |

| Abmessungen(cm) |

80*120*185 |

100*150*185 |

200*145*205 |

| Leistung 380V50HZ |

28kW |

45kW |

70kW |

| Gewicht |

660KG |

850kg |

1350kg |

| Optional |

Extended to -40 ℃~+135 ℃ |

| Hourly power consumption kWh |

-40℃ |

-10℃ |

20℃ |

| KRY-475 |

5 |

6.2 |

8.4 |

| KRYZ-475 |

2.2 |

4 |

4.8 |

| Frequency conversion saves power consumption |

56% |

35% |

43% |

| Explain |

1. Empty load test data; 2. The test condition is an ambient temperature of 20 ℃; 3. Flow rate 15L/min |

Oil cooling chiller for motor test

KRYZ 0℃~+160℃

| Modell |

KRYO-A15W |

KRYO-A25W |

KRYO-A38W |

KRYO-A15W2S |

KRYO-A25W2S |

KRYO-A38W2S |

| Temperaturbereich |

0℃ ~ +160℃ Different viscosity oils have different temperature ranges |

| Temperaturregelgenauigkeit |

±0.3℃ |

| Genauigkeit des Durchflusses |

±0.2L/min |

| Druckkontrolle |

0.2bar~2.5bar |

| Heizleistung |

15kW |

25kW |

38kW |

15kW |

25kW |

38kW |

Kühlung

Kapazität |

125℃ |

15kW |

25kW |

38kW |

15kW |

25kW |

38kW |

| 20℃ |

12kW |

20kW |

30kW |

12kW |

20kW |

30kW |

| Kältemittel |

R410A |

| Sekundäres Kältemittel |

Öl |

| Größe der Verbindung |

G3/4 |

| Water-cooled At20℃ |

3000L/H |

4200L/H |

6200L/H |

3000L/H |

4200L/H |

6200L/H |

| Größe der Verbindung |

G3/4 |

G3/4 |

G1 |

G3/4 |

G3/4 |

G1 |

direct cooling heating series

Can meet the direct cooling/direct heating for battery pack and vehicle testing and testing. This equipment is mainly used for cooling and heating capacity testing. It uses variable frequency compressor with adjustable output;

KRYZ 0℃~+160℃

| Modell |

KRYZ-5W-ZLH |

KRYZ-5W-ZL |

| KRYZ-5-ZLH |

KRYZ-5-ZL |

| Kühlleistung |

0,5kW~10kW |

0,5kW~10kW |

| Heizleistung |

0,5kW~10kW |

|

| Unterkühlungsgrad |

Kühlung 0k~8K

Heizung bei 0k~6k in Niedrigtemperaturumgebung, 6k~20k |

Kühlung 0k~8K |

| Overheating degree |

Refrigeration 2k~20k

Heating 2k~10k |

Refrigeration 2k~20k |

| Genauigkeit der Kondensationsdruckregelung |

Better than ±50kpa |

Better than ±50kpa |

| Saugdruck |

300kpa~600kpa ±10kpa |

300kpa~600kpa ±10kpa |

| Temperatur der Testumgebung des Batteriepakets |

-40℃~50℃ |

-40℃~50℃ |

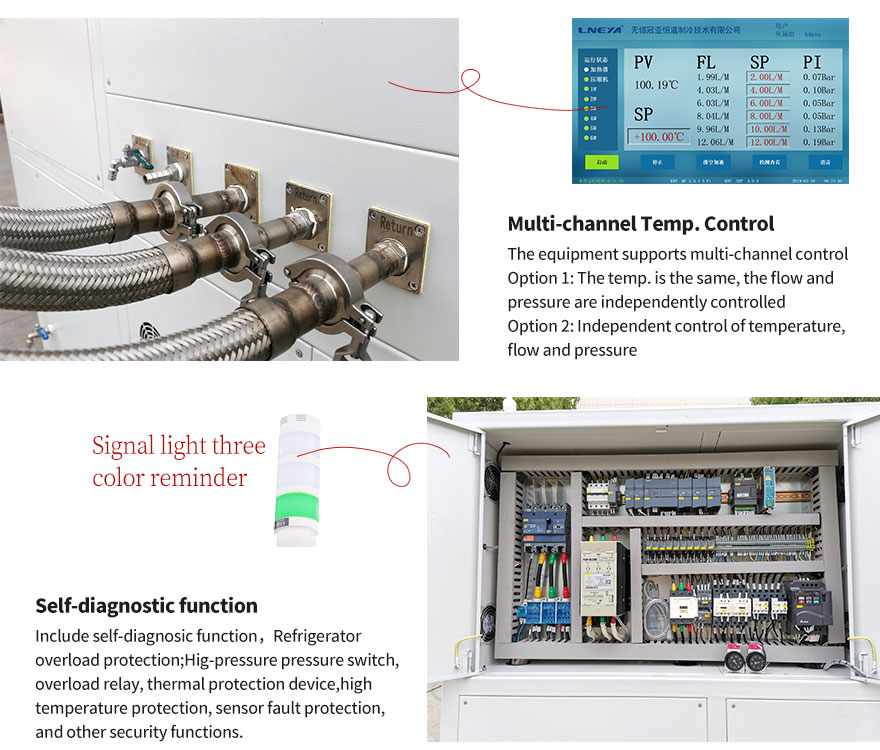

multi-channel independent temperature control

Nimmt LNEYA SPS-Steuerung, einfache Menüführung, 7″ Farb-Großbildschirm, facettenreiche und multifunktionale Bilder zur Anzeige umfassender wichtiger Dateninformationen. Die neu hinzugefügten Sicherheitsmaßnahmen gewährleisten einen kontinuierlichen unbeaufsichtigten Betrieb. Alle relevanten Betriebszustandsdaten werden kontinuierlich überwacht und auf dem Touchscreen visualisiert. Unterstützt eine unabhängige Eins-zu-Viel-Mehrkanalsteuerung, und jede Gruppe kann unabhängig eingestellt werden.

Appearance details

Application cases

The testing unit needs to use specific temperature change curves and record temperature changes; The temperature range is usually -40 ℃ to 100 ℃ (can expand to 150 ℃); When conducting tolerance testing, it is usually done in an infinite cycle.

High adaptability and wide applicationS

Suitable for more simulation test temperature control

Equipment application: new energy battery pack, battery module, battery cell, motor and controller, charger, DC/DC converter, electronic pump

EIN ANGEBOT ANFORDERN

Empfohlene Produkte

Temperature Control :-5℃~-150℃

Temperaturregelung für verschiedene Reaktoren, Destillations- oder Extraktionssysteme, Labore, Forschungsinstitute, Chemie, Pharmazie, Petrochemie, Biochemie, Medizin, Krankenhäuser, Forschungs- und Entwicklungswerkstätten, Halbleitertests, Luft- und Raumfahrt, Biologie.

Temperature Control :-120℃~350℃

Temperature control for high pressure reactor;Double-layer glass reactor;Double-layer reactor;Microchannel Reactor;Distillation system;Material aging test;Vacuum chamber etc.

Temperature Control: -40℃~100℃

Temperatur-Simulation für die Qualitätsprüfung von Fahrzeugen: Prüfung der Batterielebensdauer, Einspritzdüsen-/Motorprüfstand, Airbagtest, Komponentenprüfstand, usw. Es kann die externen Umweltbedingungen in der Klimakammer simulieren oder das interne System ersetzen, das die notwendigen tatsächlichen Temperaturbedingungen für den Prüfstand schaffen kann.

Temperature Control: -85℃~250℃

Suitable for semiconductor process wet washing, photolithography, etching, chemical meteorological deposition, physical meteorological deposition, and the electronics industry (photolithography process)

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant