Wie behebt man den Ausfall der Kältemaschine für Materialalterungstests?

Regular maintenance work for the material aging test chiller, and troubleshooting is also very important.

1. Exhaust at double high pressure, heat dissipation may be problematic.

When it is detected that the high and low pressure of the system are higher than normal, it is usually because there is air in the system or excessive refrigerant is added. At this time, it is necessary to re-evacuate and add an appropriate amount of refrigerant to solve the problem. However, there is another situation, that is, poor heat dissipation, especially when the ambient temperature is relatively high, which often leads to worse heat dissipation. The cause of this failure is generally that the heat sink is blocked, dirty, and the speed of the heat dissipation fan is not enough.

2. Refrigerant with low pressure loss, otherwise the system will be blocked.

When the high and low pressures are both low, there are two possibilities:

(1) If the system is blocked, the blocked part will produce throttling, and there will be a significant temperature difference in the throttling part, and the problem can be found by feeling it with your hands.

(2) The leakage of refrigerant leads to insufficient refrigerant. This situation is more common. At this time, the material aging test cooler detector must be used to find out the leaking location and perform replacement.

3. Low pressure, high pressure, low pressure, replace the compressor.

When the material aging test cooler pressure gauge detects that the low pressure is higher than normal, and the high pressure is lower than normal, at this time, it is recommended that the chiller refrigeration cannot achieve the effect of the normal material aging test Kühler. The reason is likely to be the wear and tear in the material aging test Kühler pump, resulting in a drop in power. At this time, it is often necessary to replace the compressor to solve the problem.

4. There is water vapor in the meter shake system, so it must be changed when it is timed out.

When the material aging test cooling machine system is working, if the pressure gauge needle keeps shaking, it means that there is moisture in the system. To solve this problem, it is generally necessary to re-evacuate, and the pumping time must be no less than 15 minutes. If necessary, the drying bottle needs to be replaced to drain the water in the system.

Verwandte Empfehlungen

-

For emergencies of the water-cooled chiller of the automatic temperature control system of the react

836In the pharmaceutical and chemicalproduction, the automatic temperature control system of the reactor is widelyvisible. In order to ensure the safe production of the enterprise, what shouldusers pay attention to when facing unexpected situation...

Details anzeigen -

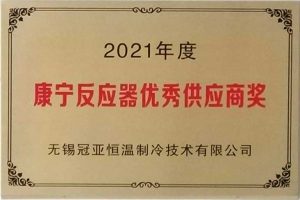

Ausgezeichnet als "Exzellenter Lieferant von Reaktor-Temperiergeräten im Jahr 2021".

3021LNEYA was awarded the "2021 Excellent Supplier of Reactor Technology" by Corning, a Fortune 500 company in the United States. Since 2015, LNEYA has won this award for 7 consecutive years. Therefore, in the reactor manufacturing industry, we have ...

Details anzeigen -

Effect of oil separator on ultra-low temperature refrigerator

1305In ultra-low temperature chillers, oil separators are an important accessory. In most cryogenic refrigerators, there are oil separators. What are the effects of oil separators on cryogenic refrigerators? Needless to say, the position of the cryoge...

Details anzeigen -

What are the functions of the controllers for semiconductor temperature control equipment?

759In the temperature control equipment of semiconductor components, each accessory has a different function. Due to the different functions, the function of the temperature control valve and controller of the semiconductor components of LNEYA is dif...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant