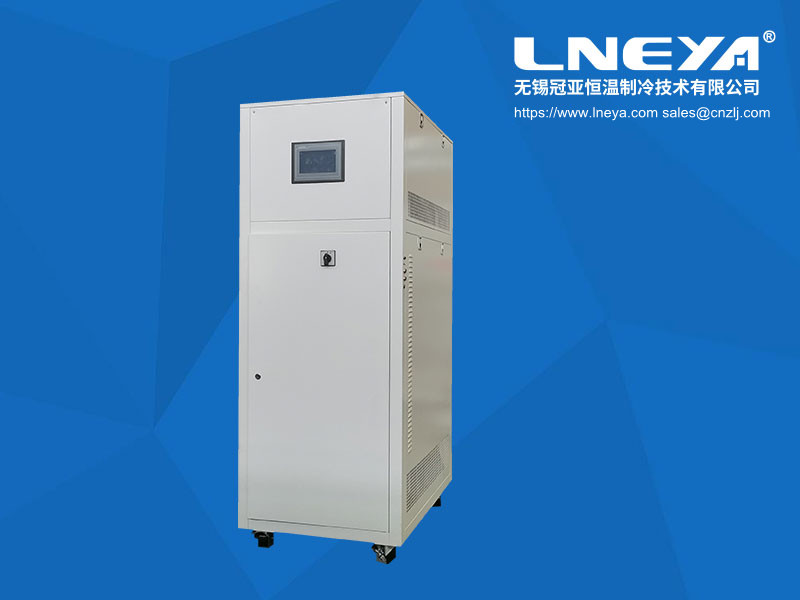

The entry point for the selection of industrial chillers

Industrial chillers are refrigeration devices that assemble refrigerators, condensers, evaporators, expansion valves, control systems, and switch boxes on a common base or frame. According to the heat rejection method of the unit, it can be divided into water-cooled and air-cooled chillers. The latter adopts heat pump circulation and is welcomed by users. After fully considering the above factors, what should we pay attention to when choosing a chiller?

The main configuration is:

Compressors, electrical components, water pumps, evaporators, condensers, high/low pressure controllers, high/low pressure gauges, LCD thermostats, expansion valves, antifreeze switches, hand valves, and fans. Screw chillers and high-precision constant temperature circulating chillers are trusted by well-known international and domestic vacuum instruments, analytical instruments, and other manufacturers.

Water circulatory system:

First inject a certain amount of water into the water tank of the chiller, cool the water through the chiller refrigeration system, and then send the low-temperature cooling water to the equipment that needs to be cooled by the water pump. The chilled water will take away the heat and increase the temperature before returning to The water tank achieves the cooling effect. The cooling water temperature can be automatically adjusted according to requirements, and long-term use can save water. Therefore, the chiller is a standard environmentally friendly and energy-saving equipment.

When choosing a chiller, you should also pay attention to the following points:

1. Generally, 2 to 4 refrigeration units are appropriate, 2 for small and medium-sized systems, 3 for larger ones, and 4 for extra-large ones. The possibility of mutual backup and switching between units should be considered. Combination schemes with different types and capacities of different units can be used in the same machine room to save energy consumption. At least one unit with a higher degree of automation, better regulation performance, and high efficiency operation under partial load should be selected among the units operating in parallel.

2. The refrigeration coefficient COP of the electric-driven refrigerator is higher than the thermal coefficient. However, each type of unit has its own characteristics and uses its strengths.

3. For the cold source of a large centralized system, it is advisable to choose a chiller with a compact structure, a small footprint, and a compressor, motor, condenser, evaporator, and automatic control components assembled on the same frame. For small systems, direct evaporative compression condensing units should be used.

4. Use domestically produced units as much as possible. my country’s refrigeration equipment industry has developed rapidly in the past ten years, and most of the product performance is close to the international advanced level, especially the small and medium-sized chillers, which are completely comparable to imported products, and have unparalleled advantages in price. Therefore, under the same conditions, domestic chillers should be selected first.

Verwandte Empfehlungen

-

Reactor Heating Circulator Related Instructions

1043Currently, reactor heating circulators are used more in the chemical industry. So, what do users need to pay attention to after purchasing? With the development of society, the process level of reactor heating circulators is becoming more and more...

Details anzeigen -

Wissensaustausch über Auswahl und Wartung von Kühlern

1131Kältemaschinen können in vielen Industriezweigen eingesetzt werden, aber wer ist der bessere Hersteller von Kältemaschinen für niedrige Temperaturen unter den Top-Kältemaschinenherstellern? Die Wahl des eigenen Modells und die Wartung sind auch sehr wichtig. Weiter, sehen Sie mit mir. 1. Bereich der...

Details anzeigen -

LNEYA stellt auf der Achema 2018 aus

837Die LNEYA Gruppe nimmt an der ACHEMA - Weltforum und Leitmesse für die Prozessindustrie in Frankfurt am Main teil und ist vom 11. bis 15. Juni 2018 an unserem Stand zu finden (detaillierte Informationen folgen),

Details anzeigen -

Battery test cooling device Chiller common configuration instructions

1272Under normal use, the battery test cooling device Chiller needs to be discovered in time when any part of the abnormality occurs. This requires a clear understanding of the basic configuration of the battery test cooling device Chiller. The batter...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant