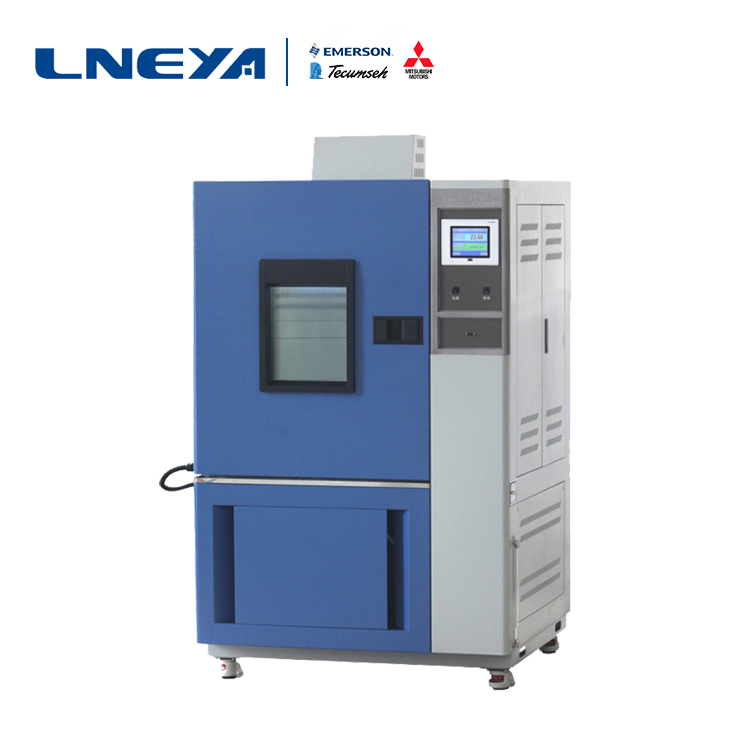

What should do if the equipment of the thermal shock test chamber does not reach the set temperature

The choice of the manufacturer of the thermal shock test chamber is related to the quality of the thermal shock test chamber. Once the quality is set, the temperature setting of the equipment will not be closed. What should I do if I encounter the temperature setting problem?

The temperature set by the thermal shock test chamber is not up to the possibility that the heat exchange humidification tube is broken. You can either repair the factory or replace the new thermal shock test chamber directly. In the high temperature test, if the temperature does not change. When testing the temperature value, the electrical system can be inspected to eliminate the fault one by one, or the temperature probe may be broken, causing the device to not work when the water temperature is lower than the set standard temperature or 37 degrees.

The temperature and temperature of the thermal shock test chamber is too long or the heating tube is aging and damaged. When the actual water temperature is far below 37 degrees, the equipment has not worked, or the work is not working. If the temperature rises directly to cause over-temperature protection, the controller fails and the control instrument must be replaced. If the temperature is too high, you need to set the PID setting parameters first.

If the temperature rises very slowly, it is necessary to check the air circulation system to see if the regulating baffle of the air circulation is normally turned on. If the temperature of the thermal shock test box rises very quickly, check whether the motor of the air circulation is running normally. Because there is a time limit for use, so the running time is too long, it is inevitable that there will be some kinds of various faults, usually pay attention to regular maintenance and maintenance, generally can be largely avoided. If you encounter a large technical problem, you should seek solutions in time with the manufacturer.

LNEYA thermal shock test box manufacturer is a professional hot and cold impact test box manufacturer integrating R&D, production and sales. It has more than ten years of experience in refrigeration and heating equipment production, and has reached cooperation with many domestic enterprises.

Verwandte Empfehlungen

-

LNEYA star refrigeration heating system SUNDI-320/420W/430W

1189Today, I will introduce the model of LNEYA's refrigeration heating system: SUNDI-320/420W/430W. It has three kinds of medium temperature range: -30°C~180°C; -40°C~180°C; -40°C~200°C. The control system is programmed to program up to 10 programs...

Details anzeigen -

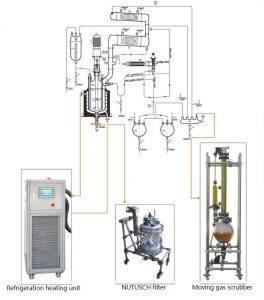

200L Kristallisationsauflösungs-Kessel Kühl- und Heizsystem

824Für die Bedürfnisse der 200L Kristallisation Auflösung Kessel Kühlung und Heizung System-Anwendungen, diese Art von Ausrüstung ist in der Regel in der Kristallisation, Auflösung und andere Prozesse in den Bereichen der chemischen Industrie, Pharmazie...

Details anzeigen -

Kühl-Heiz-System ergänzt Temperatur-Lösung für die pharmazeutische und chemische Industrie

959LNEYA ist seit mehr als zehn Jahren ein professioneller Hersteller von verschiedenen Temperaturkontrollinstrumenten. Es ist in der pharmazeutischen, chemischen, wissenschaftlichen Forschung, Industrie, neue Energie, Chip und anderen Branchen tätig. Die Forschung und Entwicklung von

Details anzeigen -

Hochwertige professionelle Ausrüstung hilft dem Labor, unendlich viele Ergebnisse zu erzielen

1741In recent years, China's economy has continued to grow. Under the development opportunity of professional high and low temperature integrated machines, laboratory scientific and technological achievements are also in sustainable development. LNEYA...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant