How Does An Industrial Chillers Work?

An industrial chiller is a type of refrigeration equipment designed to provide low-temperature cooling fluids. Its primary function is to reduce the temperature of machinery or processes by circulating chilled water or other cooling liquids. In modern manufacturing and production settings, Industriekälteanlagen play an increasingly vital role. This article will give you a comprehensive understanding of how industrial chillers work.

Fundamental Principles of Industrial Chillers

The working principle of an industrial chiller is similar to that of a household air conditioner, but with much greater cooling capacity. Industrial chillers use a refrigeration cycle to compress, condense, expand, and evaporate a refrigerant—much like Freon in home air conditioners. During this process, the refrigerant absorbs heat from its surroundings, lowering the temperature of circulating water or other fluids. This cooled fluid is then used to remove heat from various types of industrial equipment.

Phase Change

The phase change process is at the core of the refrigeration cycle. In an industrial chiller, the refrigerant undergoes phase changes—shifting between liquid and gas—to absorb and release heat efficiently.

Heat Flow

Naturally, heat flows from the higher temperature areas to the lower temperature areas. In an industrial chiller, this process removes unwanted heat from the environment.

The Refrigeration Cycle Explained

The refrigeration cycle is made up of four primary stages: compression, condensation, expansion, and evaporation.

Komprimierung

During the compression process, the compressor compresses the low-temperature, low-pressure refrigerant into a high-pressure gas. This step drives the entire refrigerant cycle.

Kondenswasser

During the condensation process, the condenser transfers heat from the system to an external medium. This enables the high-temperature refrigerant to change from a gaseous state to a liquid.

Expansion

The refrigerant experiences a drop in pressure and undergoes throttling as it passes through the expansion device.

Evaporation

During the evaporation process, the evaporator absorbs heat from circulating air or water outside the system. This causes the low-temperature refrigerant to evaporate from a liquid into a gas, creating the cooling effect.

Through this continuous refrigeration cycle, an industrial chiller can repeatedly absorb and release heat, effectively lowering the temperature of the object or medium being cooled.

Key Components of Industrial Chillers

An industrial chiller’s refrigeration system comprises four essential components: the compressor, condenser, expansion device, and evaporator. The four parts are connected in a specific sequence using copper tubing to form a closed-loop system. A fixed amount of refrigerant continuously circulates within this sealed system to enable efficient heat transfer.

Kompressor

The compressor serves as the heart of an industrial chiller. It controls the refrigerant flow and compresses it into a high-pressure gas. During this process, heat is transferred into the refrigerant, making it a crucial stage in the cooling cycle.

Verdampfer

The high-pressure refrigerant then enters the evaporator. In the evaporator, it absorbs heat from another cooling medium. This causes the refrigerant’s temperature to drop. Inside the evaporator, the refrigerant changes from a high-pressure gas to a low-pressure gas or liquid.

Verflüssiger

The low-pressure refrigerant circulates back through the cooling system to the condenser. In the condenser, it releases the absorbed heat and changes back into a high-pressure gas or liquid. Condensers typically use cooling water or another cooling medium to absorb this heat and lower the refrigerant’s temperature.

Expansion Device

The high-pressure refrigerant then flows through the expansion valve, which limits its flow and releases it into a low-pressure region.

This is the basic working principle of an industrial chiller. By understanding how it operates, you will be better equipped to choose the right chiller for your specific industrial needs.

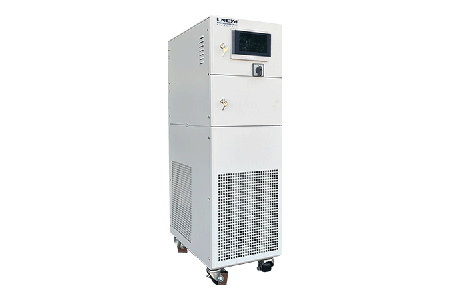

Recommended Chillers

LTZ +5℃-90℃

Glykol-Kühler

Cooling capacity 4kW~20kW

Heizleistung 3,5kW~15kW

temperature accuracy ±0.3℃

LTZ -40℃~90℃

Flüssigkeitskühler

Cooling capacity 0.7kW~11.5kW

Heating power 2.5kW~10kW

temperature accuracy ±0.3℃

LTZ +5℃~30℃

Laborkühler

Kühlleistung 23 kW ~ 155 kW

Circulation Pump MAX 5m³/h~28m³/h 2bar

Temperaturgenauigkeit ±0,5℃

LTZ -25℃~30℃

Sub-Zero-Kühler

Cooling capacity 7kW~64.5kW

Circulation Pump MAX 2.5m³/h~15m³/h 2bar

Temperaturgenauigkeit ±0,5℃

LTZ -45℃~20℃

Kühlmittelkühler

Cooling capacity 5.7kW~32.4kW

Circulation Pump MAX 1.5m³/h~7.7m³/h 2bar

Temperaturgenauigkeit ±0,5℃

LTZ -60℃~-30℃

luftgekühlte Kältemaschinen

Cooling capacity 6.2kW~31.7kW

Circulation Pump MAX 2.4m³/h~12.1m³/h 2bar

Temperaturgenauigkeit ±0,5℃

LTZ -80℃~-50℃

wassergekühlte Kältemaschinen

Cooling capacity 3.7kW~30kW

Circulation Pump MAX 2.3m³/h~12m³/h 2bar

Temperaturgenauigkeit ±0,5℃

LTZ -115℃~-80℃

kryogene Kühler

cooling capacity 0.6kW~2.8kW

Circulation Pump MAX 20L/min~40L/min 2bar

Temperaturgenauigkeit ±0,5℃

Chiller Videos

The LNEYA chiller has a temperature control range of 5°C to 35°C, adjustable heat transfer liquid temperature, stable performance, and can work continuously for 24 hours.

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant