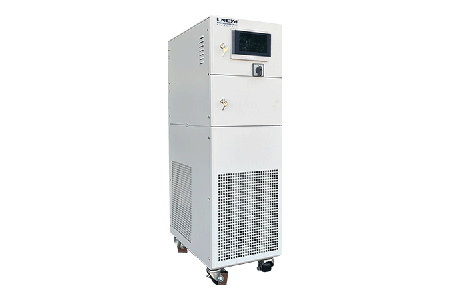

ALLE KÜHL- UND KÜHLMASCHINEN MODELL

LTZ +5℃-90℃

Glykol-Kühler

Kühlleistung 4kW~20kW

Heizleistung 3,5kW~15kW

temperature accuracy ±0.3℃

LTZ -40℃~90℃

Flüssigkeitskühler

Kühlleistung 0,7kW~11,5kW

Heizleistung 2,5kW~10kW

temperature accuracy ±0.3℃

LTZ +5℃~30℃

Laborkühler

Kühlleistung 23 kW ~ 155 kW

Circulation Pump MAX 5m³/h~28m³/h 2bar

temperature accuracy ±0.5℃

LTZ -25℃~30℃

Sub-Zero-Kühler

Kühlleistung 7kW~64.5kW

Circulation Pump MAX 2.5m³/h~15m³/h 2bar

temperature accuracy ±0.5℃

LTZ -45℃~20℃

Kühlmittelkühler

Kühlleistung 5,7kW~32,4kW

Circulation Pump MAX 1.5m³/h~7.7m³/h 2bar

temperature accuracy ±0.5℃

LTZ -60℃~-30℃

luftgekühlte Kältemaschinen

Kühlleistung 6,2kW~31,7kW

Circulation Pump MAX 2.4m³/h~12.1m³/h 2bar

temperature accuracy ±0.5℃

LTZ -80℃~-50℃

wassergekühlte Kältemaschinen

Kühlleistung 3,7kW~30kW

Circulation Pump MAX 2.3m³/h~12m³/h 2bar

temperature accuracy ±0.5℃

LTZ -115℃~-80℃

kryogene Kühler

Kühlleistung 0,6kW~2,8kW

Umwälzpumpe MAX 20L/min~40L/min 2bar

temperature accuracy ±0.5℃

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant