What should I pay attention to when adding refrigerant to a water-cooled chiller

In our life, we believe that everyone is

very familiar with refrigeration. In the central air conditioning and

industrial production process cooling industry, small water-cooled chillers is

more common. This unit is composed of a compressor in the fuselage, a

horizontal shell and tube condenser, an evaporator, a thermal expansion valve,

and some related parts. Under the cooperation of these auxiliary parts, the

overall small water cooled chiller is compact in structure, convenient in

operation and control, and is popular among the public in the market.

For refrigeration systems that do not have

a high pressure reservoir and a low pressure vapor-liquid separator, the

control of refrigerant charge is particularly important. Because the

refrigeration system is a condenser and also acts as a high-pressure reservoir,

the refrigerant is stored in the condenser, and the condenser is cooled. The

heat dissipation area is reduced and the condensing pressure is increased,

resulting in a decrease in cooling capacity.

For the control of the refrigerant charge

of such small water-cooled chillers, the following methods are followed during

the filling process:

First, touch the temperature of the

condenser casing.

The upper outlet of the condenser outlet is

heated above the outlet, and the outlet below the outlet is cool. (There is a

description of the high temperature exhaust of the compressor in the inside.

The cooling indicates that the small water-cooled chillers is a liquid space.)

Second, look at the inspiratory pressure.

Corresponding to the temperature of the

refrigerant water in the evaporator. (That is, corresponding to the evaporation

temperature.)

Third, look at the compressor return pipe

temperature.

The high-temperature unit return pipe

should be cooled and dew, but it can be dew condensation to the compressor

return valve; the low-temperature unit return pipe should be frosted, but the

frost can be connected to the compressor return valve. If condensation or frost

builds up on the compressor casing, liquid refrigerant will enter the

crankcase, causing the compressor to run back and cause liquid

problem.

The above is a partial analysis of our

LNEYA technicians for water-cooled chillers. Regarding the specific use of our

water-cooled chillers, you can contact us sales@lneya.com for more detailed

instructions.

Verwandte Empfehlungen

-

Drei häufige Ausfälle von luftgekühlten Schraubenkühlern

21491. Communication Failure: Computer-Controller steuert verschiedene Module durch Telekommunikationsleitungen und insgesamt Interface-Board, so dass die Hauptursache für die Kommunikation Fehler ist schlechter Kontakt oder Bruch der Kommunikationsleitungen, insbesondere die Schnittstelle oxida...

Details anzeigen -

Zweikanal-Kühlgeräte für die Halbleiterindustrie

1560Zweikanal-Kühlgeräte werden in einer Vielzahl von Prozessen in der Halbleiterindustrie eingesetzt. Der Hauptzweck besteht darin, eine präzise Temperaturregelung zu gewährleisten, um sicherzustellen, dass die Geräte im Halbleiterherstellungsprozess funktionsfähig...

Details anzeigen -

LNEYA hot and cold machine SUNDI manual

2039The temperature range of the hot and cold machine ranges from -120 ° C to 350 ° C. It has superior performance and unique performance. It has high precision and intelligent temperature control. The high cooling power is from 0.5 to 1200 kW. High p...

Details anzeigen -

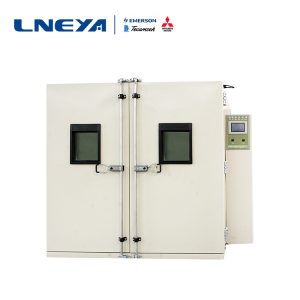

Step-by-step test box brand advantage description

1802The walk-in test box is developed and produced by LNEYA. It is specialized in pharmaceutical production technology and provides customers with various models of brands. Next, we will introduce the next step-in test box. Welcome to refer to and lea...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant