Principle Analysis of Glycol Chiller

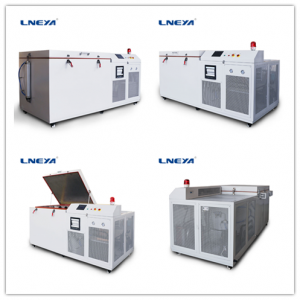

Glycol chiller is an industrial chiller

with glycol as refrigerant. The structure of glycol chiller is roughly the same

as that of ordinary industrial chiller, which is composed of compressor,

evaporator, condenser and electric control system. In order to ensure the

stable operation of glycol chiller, we suggest that you take explosion-proof

measures and buy explosion-proof glycol chiller as far as possible.

1、 Operation of compressor

In order to ensure that the pressure inside

the evaporator is low enough and that the refrigerant is at such a low

temperature, the compressor is used to extract the evaporated refrigerant and

compress the low temperature and low pressure into high temperature and high

pressure refrigerant gas.

2、 Use of condenser

High temperature and high pressure

refrigerant condenses into liquid in the condenser. The refrigerant in the

condenser releases heat in air or water lower than its temperature. Of course,

the temperature of air or water must be lower than that of refrigerant.

3、 How to throttle

After passing through the restrictor, the

refrigerant of the chiller drops from the condensation pressure to the

evaporation pressure, so the liquid from the condenser can be placed in the

liquid reservoir. At this time, the refrigerant is in the state of normal

temperature and high pressure, and then passes through the expansion valve to

reduce the boiling point, enters the evaporator, and the liquid absorbs heat

and evaporates.

4、 Endothermic evaporation

After passing through the restrictor, the

refrigerant liquid with low temperature and low pressure exchanges with the

evaporator, and the absorbed heat becomes saturated or superheated steam.

Verwandte Empfehlungen

-

Introduction to the setting and operation of the ethylene glycol chiller at minus 30℃

1533The minus 30 degree ethylene glycol chiller is a single-fluid low-temperature refrigeration unit with compressor refrigeration. How should the user set it better when operating it? 1. Automatic logout time Automatic logout means that when a user ...

Details anzeigen -

Die Rolle der chemischen und pharmazeutischen Reaktorkühlung

1993In the process of pharmaceutical synthesis and fine chemical operation, we often encounter strong exothermic reactions such as oxidation reaction and acid-base neutralization. For these strong exothermic reactions, if the control is improper or th...

Details anzeigen -

Analyse der Gründe für die Nichtkühlung kryogener Kühlanlagen

1670Ultra-Niedrigtemperatur-Kälteanlagen werden hauptsächlich in der industriellen Kälteverarbeitung eingesetzt. Im Gegensatz zu einigen Herstellern von Ultra-Niedrigtemperatur-Kälteanlagen verwendet LNEYA Ultra-Niedrigtemperatur-Kälteanlagen umweltfreundliche...

Details anzeigen -

Niedertemperaturkühler für die Herstellung von chemischen Stoffen

15221. Temperaturempfindliche Reaktionen steuern viele chemische Reaktionen, die sehr temperaturempfindlich sind, insbesondere bei der Synthese von Polymermaterialien, pharmazeutischen Zwischenprodukten und anderen Feinchemikalien. Niedrige Temp...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant