Factors affecting cooling capacity during temperature control of battery test equipment

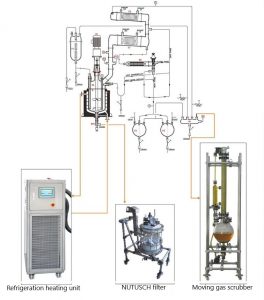

Battery Test Equipment Refrigeration System The greater the power of the battery test equipment compressor, the higher the cooling capacity. According to the size of the battery test equipment, the compressors of different types are selected. For example, the small battery test equipment is piston type, and the medium type is optional. Scroll type. When the water temperature of the battery test equipment (the evaporation temperature is different, the cooling capacity is different), the higher the cooling capacity, the lower the water temperature, the smaller the cooling capacity. Battery test equipment pump power water circulation amount, directly affects heat transfer speed, evaporator, condenser form, divided into water tank coil test, shell tube type, stainless steel plate type, etc., we need to configure according to certain requirements, thermal material Medium copper tube heat transfer is better.

There are also external factors affecting the cooling capacity of battery test equipment. Most of the battery test equipment is air-cooled. Therefore, the external ambient temperature needs to be within a reasonable range. The condensation temperature should not exceed 45 degrees. Once the cooling capacity is exceeded, it will be significantly weakened. Can not be too low, the battery test equipment air is also very important for convection, the vents can not have a barrier, reference to the standard outlet vents can not have obstacles within 1 meter.

The cooling capacity of the battery test equipment is related to the operation process of the entire battery test equipment. Therefore, the cooling capacity of the battery test equipment must be guaranteed, so that the battery and the motor operate well in the process of cooling and heating.

Verwandte Empfehlungen

-

-

LNEYA jet cooling heating temperature control device application note

1528The jet cooling heating temperature control device is applied to components to provide accurate and rapid ambient temperature for chips, modules, integrated circuit boards, electronic components, etc., and is indispensable for product electrical p...

Details anzeigen -

Wartung des Glykol-Kühlungs-Heizungs-Regelsystems

1604Abgesehen von der Aufmerksamkeit, die während des täglichen Gebrauchs erforderlich ist, sind die regelmäßige Überprüfung und Wartung des Glykol-Kühlungs-Heizungs-Regelsystems ebenfalls sehr wichtig. Um Ihnen zu helfen, lernen, Glykol Kühlung Heizung effizienter zu nutzen, LNEYA Ref...

Details anzeigen -

Instructions On Refrigeration Of Low Temperature Chiller Circulating Machine Screw Compressor

2060Due to different compressors, the performance of low temperature chiller circulation machine is also different. Screw compressor is different from the piston compressor, whose structure is more sophisticated. Therefore, if the user needs to choose...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant