Application of Microchannel Reactor Temperature Control System in the Laboratory

Accurate control of reaction temperature has a significant impact on the results in laboratories and industrial production. In recent years, the emergence of microchannel reaction temperature control systems has provided researchers with a high-precision temperature control tool. In this article, we will delve into how microchannel reaction temperature control systems can meet various research and industrial production needs through their advantages.

- 1、 What is a microchannel reaction temperature control system?

Microchannel reaction temperature control system is a technology that utilizes microchannel structures for fast and accurate temperature control. The Guanya Refrigeration Heating and Temperature Control System utilizes refrigeration and heating technology to achieve the set temperature in a short period of time and accurately control the changes in reaction temperature.

- 2、 Application Fields of Microchannel Reaction Temperature Control Systems

Chemical synthesis: In the process of chemical synthesis, accurate control of reaction temperature by a temperature control system can significantly improve synthesis efficiency and product purity. The microchannel reaction temperature control system provides a suitable temperature control tool for researchers.

Biological research: In biological research, accurate control of cell growth and protein synthesis temperature by temperature control systems is crucial for the reliability of experimental results. The microchannel reaction temperature control system can meet this requirement and provide accurate experimental data for researchers.

Materials science: In the field of materials science, the preparation and properties of various materials are closely related to temperature. The microchannel reaction temperature control system can provide researchers with more precise temperature control, thereby better studying the properties and preparation process of materials.

7 * 24 kostenlose Beratung und umfassende Lösungen anbieten

E-Mail: sales@cnzlj.com

WhatsApp: 086 13912479193

Verwandte Empfehlungen

-

Anwendungstechnik zur Erkennung von Chip-Temperaturkontrollgeräten

1684Das Chip-Temperaturkontrollgerät wird hauptsächlich im Bereich der Chip-Prüfung eingesetzt. Für verschiedene Arten von Chip-Typen, die Erkennung Technologie muss auch Aufmerksamkeit, so ist es notwendig, die Aufmerksamkeit auf die praktische Anwendung der verschiedenen...

Details anzeigen -

How to extend the service life of heat transfer oil in dynamic temperature control system?

1520In the chemical industry, the heat transfer medium of the heat transfer oil of the dynamic temperature control system of the reactor is mainly determined by the heat transfer oil itself, the operating temperature of the heat transfer oil, the dyna...

Details anzeigen -

Memory chip test equipment system program description

1734With the rapid development of the component industry, the memory chip test equipment has also made great progress. So, how much do users know about the memory chip test equipment? In order to simplify the test steps, reduce the complexity of the t...

Details anzeigen -

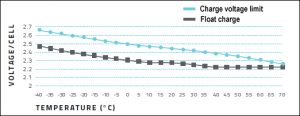

Is it right to extend battery life by lowering the ambient temperature?

1506The battery can work in a wide temperature range, but this does not allow the battery to be charged under high temperature conditions. The charging process is more delicate than the discharging process, and extreme care must be taken. Extreme cold...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant

Zur Konsultation einreichen

Wir werden Ihnen innerhalb von 24 Stunden antworten