How to choose the cooling and heating temperature control system?

The price of the refrigeration heating temperature control system is not the main factor. The main purpose is to implement the temperature control technology through the temperature control function. However, it is not the temperature control system of each refrigeration heating temperature control system manufacturer. All are the same, the industry has specialization, the technology of different manufacturers is also different, so users need to choose well, whether the refrigeration heating temperature control system that they spend a lot of money to buy is suitable for themselves, whether the quality is reliable, whether it is running efficiently.

Wuxi Guanya LNEYA refrigeration heating temperature control system has more than ten years of production experience, spending a lot of labor and money every year to carry out technical research, constantly innovating on the original technical basis of the refrigeration heating temperature control system, constantly researching, to modest The attitude constantly learns advanced technology and continuously creates a cooling and heating temperature control system that meets market demands.

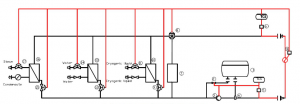

Wuxi Guanya LNEYA refrigeration heating temperature control system, suitable for high-pressure reactor cold and heat source dynamic constant temperature control, double-layer glass reactor cold and heat source dynamic constant temperature control, double-layer reactor cold and heat source dynamic constant temperature control, microchannel reactor Cold and heat source constant temperature control, small constant temperature control system, steaming system temperature control, material low temperature high temperature aging test, combined chemical cold source heat source constant temperature control, semiconductor equipment cooling heating, vacuum chamber cooling heating constant temperature control, etc. Fully closed circulation pipeline, no oil mist will be generated during high and low temperature operation, the closed pipeline will not cause pollution, no heat transfer medium will evaporate at high temperature, and it can be realized at -80 to 190 degrees without pressure. -70 to 220 degrees, -88 to 170 degrees, -55 to 250 degrees, and -30 to 300 degrees for continuous temperature control.

Said how to choose? In fact, it is very simple, the brand is the strength, Wuxi Guanya LNEYA refrigeration heating temperature control system professional manufacturers to produce efficient and energy-saving refrigeration heating temperature control system.

Verwandte Empfehlungen

-

Temperature control thermostat equipped with microchannel reactor

1977microchannel reactor temperature control

Details anzeigen -

Prozesssteuerungssystem für die chemische Synthese Temperatursteuerungssystem TCU

1750Today, let's talk about our DCS integrated control system (temperature and other control of synthetic process). Scalability: the system is an open system, which provides standard TCP / P data communication interface protocol, interface software an...

Details anzeigen -

How to use a multimeter to test the components of the chip test temperature control machine?

1583The chip test temperature controller is used for IC, CPU, GPU, DPU, BGA, FCBGA, LGA, QFN, QFP, CSP, WLCSP, Bare Die, and other Device Under Test. So, how to use a multimeter for these commonly used components What about testing? For electronic com...

Details anzeigen -

Welche Prüfungen werden bei Kühlwasserkühlern für neue Energieunternehmen durchgeführt?

1368Im Rahmen der Produktentwicklung, der Produktion und der Qualitätskontrolle führen die Unternehmen der neuen Energiewirtschaft eine Reihe von Tests mit Kaltwassersätzen durch. Kaltwassersätze spielen bei diesen Tests eine wichtige Rolle, um die Leistung zu...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant