-80 °C refrigerator manufacturer operating equipment points

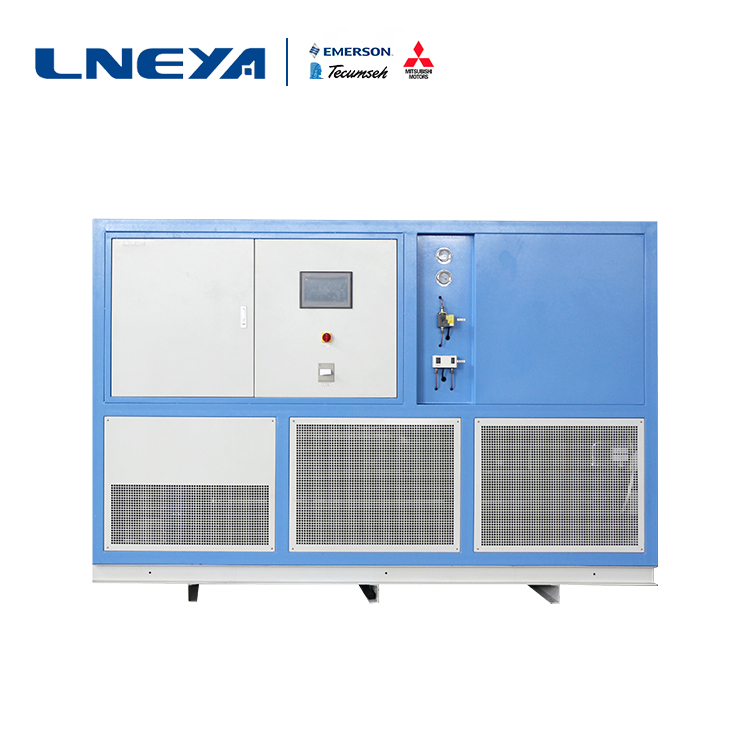

When the user chooses the -80 °C refrigerator, it is definitely necessary to have a reliable quality. Wuxi Guanya (LNEYA)-80 °C refrigerator should pay attention to its operation details during operation to avoid equipment failure caused by improper operation.

The following items should be mastered during use. Please check if the -80 °C refrigerator is damaged during installation, and choose the right place for installation and future maintenance. The site where the unit is installed must be the floor, mounting mat or foundation with a level of 6.4 mm and can withstand the operating weight of the unit. – It should be placed in a machine room with a room temperature of 4.4-43.3 °C. There should be enough space around and above the unit for routine maintenance work. A pipe space for cleaning the condenser tube bundle should be left at one end of the device, or a door hole or other suitable hole can be used.

Select the water pipe of the appropriate pipe diameter, the cooling system and the cold water system of the -80 °C refrigerator unit during high power operation, and connect them correctly. For normal applications, the water flow rate through the evaporator and condenser is between 1.0 and 3.6 m/s.

Under any load, the water flow rate should be stable. All chilled water and cooling water pipes should be designed and installed according to the conventional method. The chilled water pump should be located on the inlet pipe of the unit to ensure the positive pressure and flow in the unit. The piping should be provided with a damping tube to ensure proper flexibility and to prevent the evaporator water from being drained when the pump is shut down. The piping should have a solid support independent of the -80 °C refrigeration unit to prevent stress from being applied to the refrigeration unit components. The hangers are set up to facilitate pipe alignment.

-80 °C refrigerator manufacturers will provide corresponding instructions when the equipment is shipped from the factory, users need to read and operate carefully when using.

Verwandte Empfehlungen

-

LNEYA Low temperature thermostatic bath instructions

1989Low temperature thermostat is widely used in petroleum, chemical industry, electronic instruments, physical, chemical and biological engineering, medicine and health, life sciences, food industry, physical testing and chemical analysis and researc...

Details anzeigen -

The Effect of Battery Test Temperature Simulation System on Testing Electric/Hybrid Vehicle Cooling

1741In the electric vehicle industry, batteries are an important part of automobiles, and their performance directly affects the performance of hybrid/electric vehicles. For this reason, relevant manufacturers in the market have launched a battery coo...

Details anzeigen -

Advantages of Industrial Chillers in Refrigeration

1686In recent years, the manufacturing industryhas entered a golden age. The market competition is fierce, and therequirements for product quality have been greatly improved. In fact, in theprocess of improving product quality, manufacturers oft...

Details anzeigen -

Detailed Electric Vehicle Motor Test And Test System

1583New energy vehicles need to have power system, drive system, control system integration test capability, and electronic electronic control test system function test capability. For component manufacturers, this test development capability is also ...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant