Relationship Between Condensation Temperature And Condensation Temperature In Ultra Low Temperature

The chilling temperature of the ultra low temperature recirculating chillers refers to the temperature at which the state of the substance changes from a gaseous state to a liquid state under a certain pressure. Different substances have different condensation temperatures. For the same substance, changes in external pressure can also cause changes in the condensing temperature. The condensation temperature of the pure substance is a temperature point, and for the mixture, the boiling range elongation condensation is a temperature range. In general, as the outside air pressure increases, the condensing temperature also rises, and vice versa. In short, it is a function of matter, composition and pressure.

The level of condensation temperature depends mainly on the temperature and flow rate of the cooling medium, the condensation area and the form of the condenser. Reducing the condensing temperature can increase the refrigeration capacity of the compressor and reduce the power consumption, thereby increasing the refrigeration coefficient and improving the economics of operation. However, the condensing temperature should not be too low, otherwise it will affect the circulation of the refrigerant, and the cooling capacity will decrease. If the condensing temperature is too high, not only the cooling capacity will decrease, but also the power consumption will increase, and the exhaust temperature of the compressor will increase, the temperature of the lubricating oil will increase, and the viscosity will decrease.

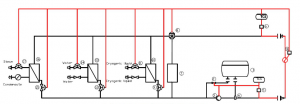

There is also a certain correspondence between the condensation temperature of the ultra low temperature recirculating chiller and the condensing pressure. Therefore, the adjustment of the condensing temperature can also be achieved by adjusting the condensing pressure. When the temperature of the cooling medium (water or air) is constant, the adjustment of the condensing pressure can be achieved by changing the flow rate and the condensation area of the cooling medium. The flow rate of the cooling medium is increased, and the flow rate is correspondingly increased, the heat transfer temperature difference can be reduced, thereby reducing the condensation temperature; and increasing the heat transfer area can also achieve the purpose of reducing the condensation pressure.

Verwandte Empfehlungen

-

Hot and cold dynamic constant temperature control equipment cryopump installation points

1765The performance of each component in the cold and heat source dynamic constant temperature control equipment is different. We must make full use of each accessory to make the equipment run better. The cryopump is one of the main accessories, and i...

Details anzeigen -

Das Kälteprinzip des Glykol-Kältesystems

1662Manchmal muss der Kälteträger eine Temperatur unter 0 C erreichen. Wenn das Eis den Koch trägt, friert er ein, so dass die Zugabe von Gefrierschutzflüssigkeit das Einfrieren verhindern kann, und Glykol kann das Einfrieren verhindern. glycol chillers ,

Details anzeigen -

LNEYA isolation explosion-proof cooling heating circulation system SR-35N

1046LNEYA isolation explosion-proof cooling and heating circulation system mainly uses heat transfer medium for heating and refrigerant for cooling. So what are the main accessories in the isolated cold and hot water circulation system? What effect do...

Details anzeigen -

Prozesssteuerungssystem für die chemische Synthese Temperatursteuerungssystem TCU

1748Today, let's talk about our DCS integrated control system (temperature and other control of synthetic process). Scalability: the system is an open system, which provides standard TCP / P data communication interface protocol, interface software an...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant