Water cooled low-temperature circulators in the testing industry of new energy vehicles

The development of the new energy vehicle industry is relatively rapid. Driven by technological innovation, it is believed that the new energy vehicle industry is facing opportunities. However, with the development of the new energy vehicle industry, some problems have been exposed in the power battery system, such as uneven quality reference, poor technical level, and weak reliability. So for new energy vehicle companies and power battery manufacturers, the stability test of power batteries is an inspection process, which is an important detection method to reduce thermal runaway during power battery operation and avoid spontaneous combustion accidents.

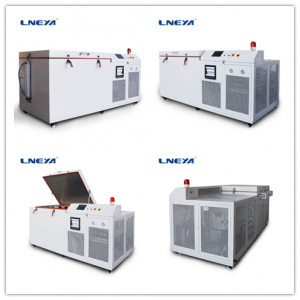

LNEYA has explored the application of industrial refrigeration equipment in the new energy vehicle industry. Through continuous exploration, it has accumulated valuable experience in inspection processes such as battery pack testing and temperature control, battery pack PACK liquid cooling testing, and low-temperature testing. Combining its technical advantages in industrial refrigeration equipment research and design, it has developed specialized chiller equipment suitable for battery pack PACK liquid cooling testing, low-temperature testing, temperature impact, and other aspects.

In the hydrogen energy industry, during the testing and testing of hydrogen fuel engines, reactions generate a large amount of heat energy. Timely cooling can extend the service life of the test bench and improve the overall testing effect. A domestic enterprise engaged in hydrogen fuel cells and stacks needs to promptly cool down the engine test bench during hydrogen fuel cell engine testing to ensure its normal operation, reduce equipment loss rate, and extend service life due to expanding its hydrogen energy production base.

The water-cooled refrigeration constant temperature refrigerator supports one drag multiple, that is, one refrigeration heating temperature control flow host can control 2 to 6 different test benches or demand temperature control flow devices. Guanya Refrigeration supports two one drag multiple modes, one is that temperature/flow/pressure can be independently controlled (T series), and the other is that temperature groups are consistent, and flow/pressure can be independently controlled (S series).

Verwandte Empfehlungen

-

Description of LNEYA industrial ultra-low temperature freezer

1813LNEYA industrial ultra-low temperature freezer is mainly used in industrial cold treatment to precipitate uniform, fine and dispersed carbides on the metal structure matrix. The appearance of such a carbide will bring about a significant increase ...

Details anzeigen -

Temperaturanforderungen für Ionenimplantationskühler in Halbleiterfertigungsprozessen

1316Ion implantation is an important step in semiconductor manufacturing processes to precisely dope and control the electrical properties of semiconductor materials by implanting high-energy ions into them. This process generates a lot of hea...

Details anzeigen -

What should pay attention to after purchasing the -150°C ultra-low temperature refrigerator?

1850-150 ° C ultra-low temperature refrigerator is used in the industry, so what should users pay attention to after purchasing equipment from the manufacturer? Next, Wuxi Guanya (LNEYA)-150 °C ultra-low temperature refrigerator manufacturers for ever...

Details anzeigen -

Simulation control of temperature change in the cooling and heating temperature control system of th

1312Industrial cooling and heating temperature control system is a temperature control equipment used in the cooling and heating process of reaction kettle in the pharmaceutical and chemical industry. What are the characteristics of lneya's equipment?...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant