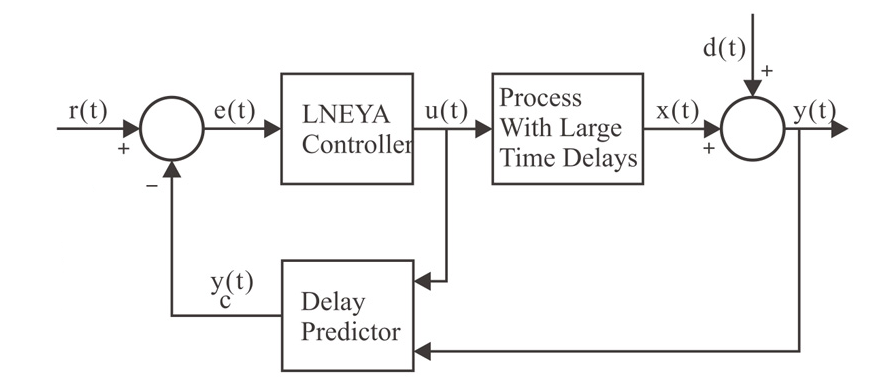

Dynamische Temperaturregelung

wie Reaktionen

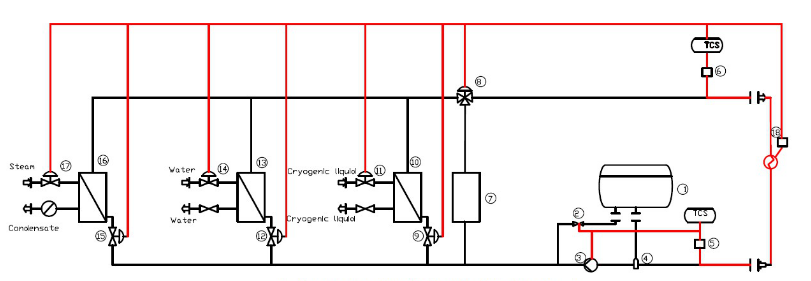

Einige biochemische Reaktionen müssen wiederholt zwischen hohen und niedrigen Temperaturen wechseln. Anpassung möglich

Prüfmittelgarantie

wie mechanische Kühlung

Eine Überhitzung der Geräte beschleunigt deren Alterung und kann sogar zu Bränden führen, was sich auf die Lebensdauer der Geräte auswirkt.

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant