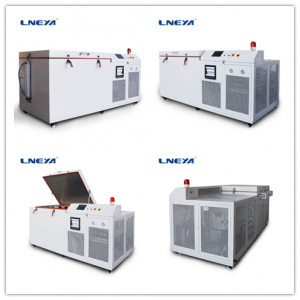

The advantages of water cooled chiller you need to know

Industrial

chillers can be generally divided into water-cooled and air-cooled according to

the type of refrigeration. The heat exchange medium of Water Cooled Chillers is

water.LNEYA has designed and developed a new type of temperature control

equipment according to the needs of many customers, which can be customized for

different process selections to achieve the cooling effect.

Our

water cooled chiller adopts a fully enclosed circulating pipeline, which avoids

the phenomenon of high temperature oil mist and low temperature absorption of

water, ensuring that the working environment will not produce pungent smell,

and also avoids the situation that the heat transfer medium becomes viscous and

adheres to the pipeline after absorbing water, resulting in poor refrigeration

effect. The water cooled chiller can meet the requirements of the enterprise’s

low temperature environment to achieve the purpose of high-efficiency operation

of the equipment.

Wasser

cooled chillers mainly rely on water circulation to cool down. In the actual

operation process, in order to achieve a better cooling effect, the water cooled

chiller adopts circulating water to continuously circulate, which has a larger

flow rate than tap water, and can achieve a relatively high energy efficiency

ratio and improve the service efficiency of the water cooled chiller.

Therefore, the number of customers buying water cooled chillers is also

increasing.

Die

water cooled chiller has a relatively strong environmental adaptability and can

also operate the chiller in an efficient way. Under the operation of a large

water cooled chiller, the overall load is relatively low. Even if it runs for a

long time, water cooled chillers can meet the needs of low-temperature

environments with relatively little energy consumption. Therefore, the water cooled

chiller has greater advantages in the use of the same equipment.

Verwandte Empfehlungen

-

Die Rolle der chemischen und pharmazeutischen Reaktorkühlung

1238In the process of pharmaceutical synthesis and fine chemical operation, we often encounter strong exothermic reactions such as oxidation reaction and acid-base neutralization. For these strong exothermic reactions, if the control is improper or th...

Details anzeigen -

LNEYA stellt auf der Achema 2018 aus

837Die LNEYA Gruppe nimmt an der ACHEMA - Weltforum und Leitmesse für die Prozessindustrie in Frankfurt am Main teil und ist vom 11. bis 15. Juni 2018 an unserem Stand zu finden (detaillierte Informationen folgen),

Details anzeigen -

How to choose the cooling and heating temperature control system?

1098The price of the refrigeration heating temperature control system is not the main factor. The main purpose is to implement the temperature control technology through the temperature control function. However, it is not the temperature control syst...

Details anzeigen -

Description of LNEYA industrial ultra-low temperature freezer

1238LNEYA industrial ultra-low temperature freezer is mainly used in industrial cold treatment to precipitate uniform, fine and dispersed carbides on the metal structure matrix. The appearance of such a carbide will bring about a significant increase ...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant