-80 °C refrigerator manufacturer operating equipment points

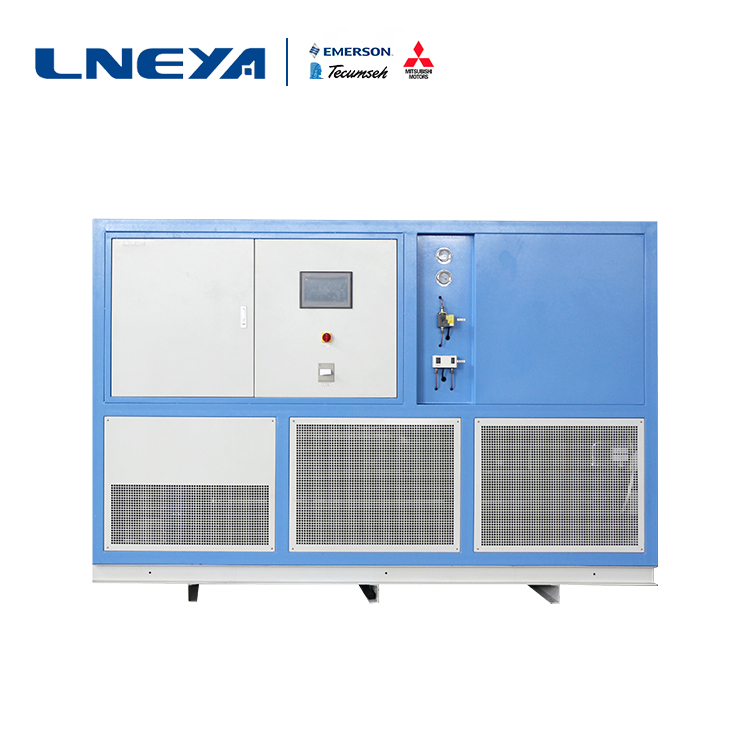

When the user chooses the -80 °C refrigerator, it is definitely necessary to have a reliable quality. Wuxi Guanya (LNEYA)-80 °C refrigerator should pay attention to its operation details during operation to avoid equipment failure caused by improper operation.

The following items should be mastered during use. Please check if the -80 °C refrigerator is damaged during installation, and choose the right place for installation and future maintenance. The site where the unit is installed must be the floor, mounting mat or foundation with a level of 6.4 mm and can withstand the operating weight of the unit. – It should be placed in a machine room with a room temperature of 4.4-43.3 °C. There should be enough space around and above the unit for routine maintenance work. A pipe space for cleaning the condenser tube bundle should be left at one end of the device, or a door hole or other suitable hole can be used.

Select the water pipe of the appropriate pipe diameter, the cooling system and the cold water system of the -80 °C refrigerator unit during high power operation, and connect them correctly. For normal applications, the water flow rate through the evaporator and condenser is between 1.0 and 3.6 m/s.

Under any load, the water flow rate should be stable. All chilled water and cooling water pipes should be designed and installed according to the conventional method. The chilled water pump should be located on the inlet pipe of the unit to ensure the positive pressure and flow in the unit. The piping should be provided with a damping tube to ensure proper flexibility and to prevent the evaporator water from being drained when the pump is shut down. The piping should have a solid support independent of the -80 °C refrigeration unit to prevent stress from being applied to the refrigeration unit components. The hangers are set up to facilitate pipe alignment.

-80 °C refrigerator manufacturers will provide corresponding instructions when the equipment is shipped from the factory, users need to read and operate carefully when using.

Verwandte Empfehlungen

-

Energy Conservation is Crucial for Developing Ultra Low Temperature Recirculating Chillers

2201With the continuous development of chemical, refrigeration and pharmaceutical industries, environmental pollution is put on the agenda earlier. As an editor of which is the industrial chiller, I can say that except for corresponding to the environ...

Details anzeigen -

What should I pay attention to when replacing a water-cooled chiller compressor

999Once the compressor of the water-cooledchiller fails, the compressor needs to be replaced in time, but the replacementof the compressor is not as simple as imagined.Before the water-cooled chiller compressoris replaced, the reasons for the dama...

Details anzeigen -

Application and advantages of new energy automotive motor test equipment

993LNEYA's new energy motor test equipment is used in HEV (Hybrid Electric Vehicle), BEV (Electric Vehicle), Hydrogen Power Vehicle, Fuel Cell Electric Vehicle, EREV (Extended Range Electric Vehicle) and other new energy vehicles. LNEYA's equipment a...

Details anzeigen -

Wie wählt man die Kältemaschine zur Kühlung des Mischtanks aus?

1155Mischbehälter werden in den Bereichen Beschichtungen, Medizin, Baustoffe, Chemikalien, Pigmente, Harze, Lebensmittel, wissenschaftliche Forschung und anderen Branchen zum Rühren, Mischen, Vermengen und Homogenisieren von Materialien verwendet. Der Mischbehälter erzeugt während des Mischvorgangs Wärme...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant