Reparaturverfahren für Kompressoren von Maschinen mit geschlossenem Warm- und Kaltzyklus

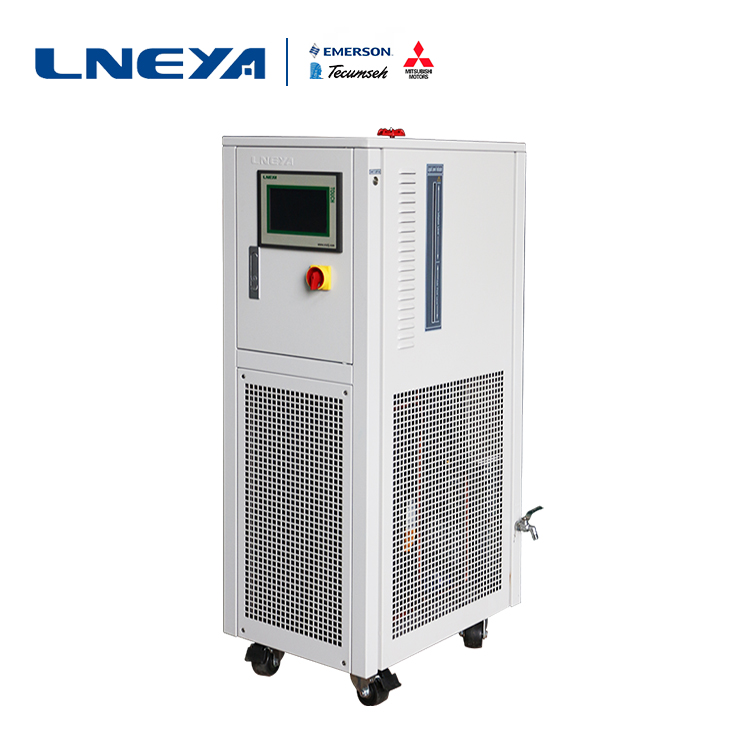

LNEYA’s closed-type hot and cold cycle machine adopts single-machine self-cascading refrigeration technology, and its compressor also uses the brand compressor, which is more stable in performance. Therefore, it is easy to choose a series of compressors with general performance. malfunction.

If the screw compressor is used in the closed type hot and cold cycle machine, the operation and maintenance process is very simple. Before the screw compressor of the closed type hot and cold cycle machine must be overhauled, if possible, the slide valve is unloaded to the “0” position. , normal shutdown, cut off the power. The compressor can be disassembled by cutting off the piping connected to the compressor and discharging the refrigerant and lubricating oil in the compressor. Be careful to develop good habits when disassembling. Parts of different parts should be placed separately and the necessary assembly marks should be made.

After removing the pipes, couplings and anchor bolts connected to the compressor of the closed type hot and cold cycle machine, the compressor is lifted to the workplace. Remove the suction filter, suction check valve, and remove the energy indicator. Remove the locating pin, remove the suction end cap in parallel, and take out the oil piston and balance piston. Note that when the positioning pin is taken, it can only be pulled out and cannot be pulled out. Be sure to take out the positioning pin first, then remove all the bolts to prevent the weight of the suction end cover from acting on the positioning pin and bend the positioning pin. Remove the shaft cover and remove the shaft seal. Be careful not to touch the moving and stationary rings, remove the positioning pin, remove the exhaust end cap, and remove the bearing gland, lock nut, washer, thrust bearing, adjusting pad, etc. To remove the locknut, use a special special tool and first open the lock tab of the lock washer. Mark them at any time and place them separately. After removing the compressor positioning pin, remove the exhaust end seat and use the special eye bolt to slowly and smoothly remove the active rotor, and do not collide with the body. At this time, the driven rotor rotates accordingly, and the driven rotor is taken out and the spool is taken out.

Wuxi Guanya (LNEYA) closed type hot and cold cycle compressor adopts Hanzhong, Bitzer, Copeland, Danfoss and other brands, and its performance is reliable. It is suitable for refrigeration, chemical and other industries, and has been highly praised by users.

Verwandte Empfehlungen

-

Use and maintenance of laboratory/bioengineering temperature control system

9421. Read the equipment manual carefully before use, get familiar with the operation process and key instructions, and operate in strict accordance with the conditions specified in the manual. 2. When moving the laboratory/bioengineering temperatur...

Details anzeigen -

Reglerfunktion einer industriellen Kältemaschine

1362Bei der Verwendung von industriellen Kaltwassersätzen ist der Regler der wichtigste Punkt. Kennen Sie also die Funktion des Temperaturreglers des Kaltwassersatzes? Heute, wir werden darüber sprechen! 1. Der Strömungsschalter der Kältemaschine wird als Steuerung oder Unterbrechung verwendet...

Details anzeigen -

How To Reduce Operating Costs For Electric Vehicle Power Battery Testing Equipment?

985Since many harsh environments easily affect the operating power of electric vehicle power battery testing equipment, in order to ensure the safety of equipment operation, enterprises need to choose a suitable safety environment when installing ele...

Details anzeigen -

Popularization of knowledge of Semiconductor Back-End Test high and low temperature control system

1062The Semiconductor Back-End Test high and low temperature control system is a necessary testing equipment for the metal, component, electronic and other material industries. It is used to test the degree of endurance of material structures or compo...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant