Analyse der Gründe für die Nichtkühlung kryogener Kühlanlagen

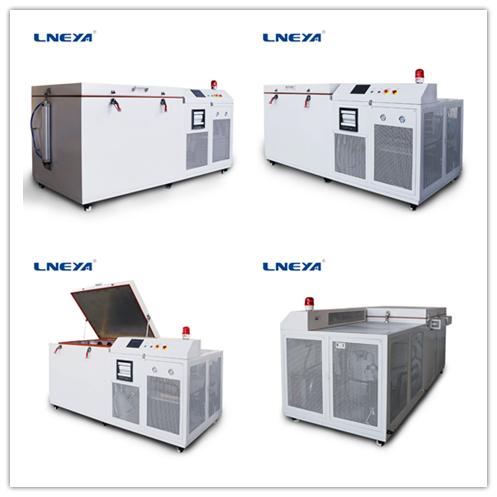

Ultra-low temperature refrigeration equipment is mainly used in industrial cold processing. Unlike some manufacturers of ultra-low temperature refrigeration equipment, LNEYA ultra-low temperature refrigeration equipment uses environmentally friendly refrigerant, which is conducive to the operation of ultra-low temperature refrigeration equipment. If the ultra-low temperature refrigeration equipment does not cool, how to Solve it?

Generally speaking, if the ultra-low temperature freezer is not cooled, there are four main reasons. One is that the filter is clogged. When the filter is clogged, the dust on the condenser will accumulate more and more, and the refrigeration effect of the refrigeration equipment will be affected over time. . In the long run, it may even cause refrigeration equipment to fail to cool. Solution to filter blockage: Clean the filter regularly or irregularly. It is also possible that the coolant content is small, and the ultra-low temperature refrigeration coolant content is too small, which may cause the equipment to not absorb oil and reduce the cooling effect. Less coolant content Solution: Always check the coolant to see if the coolant level is maintained at high or low, and add coolant when the coolant is too low.

If the refrigeration equipment is not cooled, there may be a lack of refrigerant. In the refrigeration, after the refrigerant is used for a long time, the refrigerant will volatilize after a long use time, thereby affecting the cooling effect. Solution: Refrigerant may have certain harm to the human body, so if you encounter this situation, you should find a professional refrigeration equipment company to add. There is also the possibility that the ultra-low temperature refrigeration supply voltage is low or the power of the refrigeration equipment is insufficient, and the equipment may not be cooled.

In general, the reasons and solutions for the non-refrigeration of ultra-low temperature refrigeration equipment are as shown above. It is recommended to find that the refrigeration faults are resolved in time to avoid affecting the production of the enterprise.

Verwandte Empfehlungen

-

Wie kann die Lebensdauer des dynamischen Temperaturkontrollsystems gewartet und verlängert werden?

958Dynamic temperature control system is a fully enclosed refrigeration and heating temperature control device that provides cold and heat sources. The service life is related to the usual maintenance and cleaning. Dynamic temperature control system...

Details anzeigen -

Why choose LNEYA’s reactor automatic temperature control equipment?

1286With the rapid development of pharmaceutical and chemical industry, the market demand for automatic temperature control equipment for reactors is expanding. The requirements for automatic temperature control equipment for reactors are also rising,...

Details anzeigen -

Wie vakuumiert man das Tiefkühlsystem der Ultratiefkühltruhe?

1031Wenn der Anschluss des LNEYA-Ultra-Tiefkühlgeräts an den Innen- und Außenbereich abgeschlossen ist, beobachten Sie die Ölanzeige der Ölpumpe, um zu sehen, ob genügend Öl vorhanden ist, und starten Sie dann die Vakuumpumpe, um zu sehen, ob sie normal funktioniert. Dann schrauben Sie das große Ventil zurück ...

Details anzeigen -

Installation method of heating and cooling temperature control system for automobile motor

1070In chemical and pharmaceutical, chemical laboratories, pilot plants and other industrial processes, the heating and cooling temperature control system is the most used equipment for temperature control in chemical manufacturing, so a highly dynami...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant