Explosion-proof high temperature and low temperature machine factory note

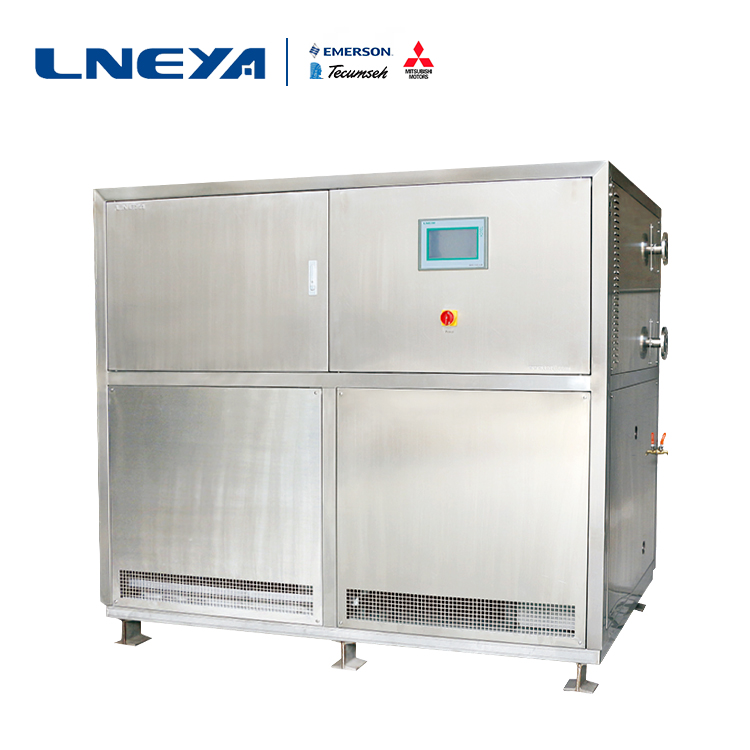

Explosion-proof high and low temperature integrated machine is the main product of LNEYA production and sales. It adopts dynamic temperature control system and fully closed pipeline design. The operation effect is relatively stable. What common problems should be paid attention to during the operation?

Explosion-proof high and low temperature integrated machine should be installed away from heat source, no direct sunlight, good ventilation, and the ambient temperature should not exceed 35 °C to prevent the condenser from dissipating heat and affecting the ice making effect. The installed floor should be solid and flat and must be level, as this will result in no ice detachment and noise during operation.

The explosion-proof high and low temperature integrated machine has a gap of not less than 30cm on the back and left and right sides, and the top clearance is not less than 60cm. Explosion-proof high and low temperature integrated machine should use independent power supply, special line power supply and equipped with fuse and leakage protection switch, and must be grounded reliably. Water should meet the national drinking water standards, and a water filtration device should be installed to filter impurities in the water to avoid clogging the water pipes, polluting the water tank, and affecting the cooling performance.

When cleaning the explosion-proof high and low temperature integrated machine, the power should be turned off. It is strictly forbidden to use the water pipe to directly align with the body. Use neutral detergent to scrub. Do not use acidic or alkaline corrosive solvents. It is necessary to unscrew the inlet hose head two months and clean the inlet valve screen to prevent the sand mud impurities from clogging the water inlet, which causes the water intake to become smaller, resulting in no refrigeration. Explosion-proof high and low temperature integrated machine must clean the surface of the condenser every two months, and poor condensation and heat dissipation will cause damage to the compressor components. When cleaning, use a vacuum cleaner, a small brush, etc. to clean the condensed surface oil dust. Do not use a sharp metal tool to clean it to avoid damaging the condenser.

Water pipes, sinks, storage refrigerators and protective film should be cleaned every two months. When not in use, it should be cleaned, and the ice mold and the moisture in the box should be dried with a hair dryer, and placed in a place free of corrosive gas and ventilated and dry, to avoid open storage. Also need to pay attention to maintenance, pay attention to the strength, do not damage the explosion-proof high and low temperature machine.

Verwandte Empfehlungen

-

Heating and cooling system for chemical reaction kettle reaction process

1155In the process of chemical chemical reaction, material temperature is an important production process parameter. For example, in salt crystallization, solution separation, organic pigment and intermediate processing, temperature control is particu...

Details anzeigen -

Trouble shooting method for water cut off of cooling system driven by wheel motor

999Long-term use of the wheel motor to drive the cooling system can encounter any kind of failure. For the wheel-side motor drive cooling system, if there is a water cut problem, it is very dangerous and must be dealt with in a timely and effective m...

Details anzeigen -

Warum brauchen Elektrounternehmen industrielle Kältemaschinen für Kühlsysteme?

910When electrical equipment is operating outdoors, it may encounter high temperature environments. For example, in direct sunlight in the summer, the temperature may be very high. If the equipment overheats, it will affect performance or even ...

Details anzeigen -

Niedertemperatur-Kühlsystem in Trocknungs- und Gefriertrocknungsanlagen vorhanden

817In der Trocknungs- und Gefriertrocknungsanlage ist das Niedertemperatur-Kühlsystem eine der Kernkomponenten, die für die Erzielung des Gefriertrocknungsprozesses entscheidend ist. Die Gefriertrocknung (Gefriertrocknung) ist eine wirksame Methode zur Entfernung von Feuchtigkeit...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant