Failures of Heating Cooling Circulators

Die Heiz-Kühl-Umwälzpumpe can be used in many chemical pharmaceuticals and laboratories. Then, how to solve the failures of the heating cooling circulator?

Failure of circulating pump

The failure of the circulating pump is generally the heat overload of the circulating pump. There are 4 main reasons for this failure:

1. The external circulation pipeline is too long. It is suggested to shorten the external circulation pipeline, reduce the bending of the external circulation pipeline, and then click the Reset button of the electric cabinet surface heat relay;

2. The circulating pipe is blocked. It is suggested to check the degree of cleanliness of the circulating pipe, install a filter, and then click the Reset button of the electric cabinet heat relay;

3. The circulation pump voltage is too low. It is suggested to measure whether the circulation pump voltage is in line with the prescribed range, improve the voltage environment, and then click the Reset button of the electric cabinet heat relay;

4. The regulating current of the heat relay is too small. It is suggested to measure the pump current, compare the heat relay range, turn up the heat relay current properly with the cross screwdriver, and then click the Reset button of the electric cabinet heat relay.

Failure of sensor

The great possibility of sensor failure is the wiring error. At this time, check the wiring in time, and we should pay attention to two kinds of situations, one is the sensor is short-circuited or the temperature is < -160 ℃, the other is the sensor is open circuited or the temperature is > 349℃.

If the sensor is short-circuited or the temperature is <-160 ℃, it may be the fault of the sensor itself. At this time, change the sensor (there is a standby sensor in the equipment line slot), if the sensor connection is wrong, it is suggested to check the connection condition (the control circuit diagram) to correct.

If the sensor is open circuited or the temperature is > 349 ℃, it should be the fault of the sensor itself. At this time, replace the sensor in time (there is a standby sensor in the equipment line slot). It is necessary to pay attention to whether the temperature is too high and beyond the range. If the equipment is out of electricity, check the power supply of the equipment.

The above two failures of the heating cooling circulator are relatively simple. I believe that you can quickly solve these failures with these tips.

Verwandte Empfehlungen

-

Beschreibung der Einschaltauslösung des Hochleistungskühlschranks

903Der Wuxi Guanya LNEYA Hochleistungskühlschrank ist mit Markenzubehör ausgestattet. Die Kühlleistung des gesamten Hochleistungskühlschranks ist relativ stabil. Sobald die Power-On-Auslösung auftritt, muss sie rechtzeitig verarbeitet werden, um die...

Details anzeigen -

Hersteller Analyse - 90 ° C einstufige Kälteanlage Verdichter gemeinsame Form

1146Es gibt viele Arten von Verdichtern in der einstufigen -90 °C-Kälteanlage. Die am häufigsten verwendeten sind die Kolbenkompressoren. Aber wissen Sie, welche Typen es gibt? In der Kälteanlagenbranche sind die am häufigsten verwendeten Kältemittelverdichter...

Details anzeigen -

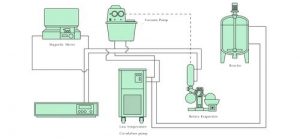

Low-temperature coolant circulation pump used with rotary evaporator

1258The chemical and pharmaceutical fields are the largest end consumer markets for cryogenic coolant circulation pumps. With the increasing demand for low-temperature coolant circulation pumps in this market, the application of cryogenic pumps in the...

Details anzeigen -

How to ground the electric vehicle battery test driver?

1012The electric vehicle battery test is in the running state, and it is necessary to understand the operation of the accessories, and the drive and other accessories are in operation. If the electric vehicle battery test is not isolated between the A...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant