How Many Types of Test Chambers Are There

Have you ever bought a product that started having problems after only a few uses? Sometimes, everyone who purchased the same batch experiences similar issues. Why does this happen? Often, these products were not tested under the real conditions they might face, such as temperature, humidity, altitude, or vibration, before mass production. This is a design flaw.

To prevent such problems, most manufacturers use Prüfkammern during product development and design. These chambers simulate real-world conditions to optimize the product before it reaches customers.

So, what is a test chamber and what types are available?

What is a Test Chamber

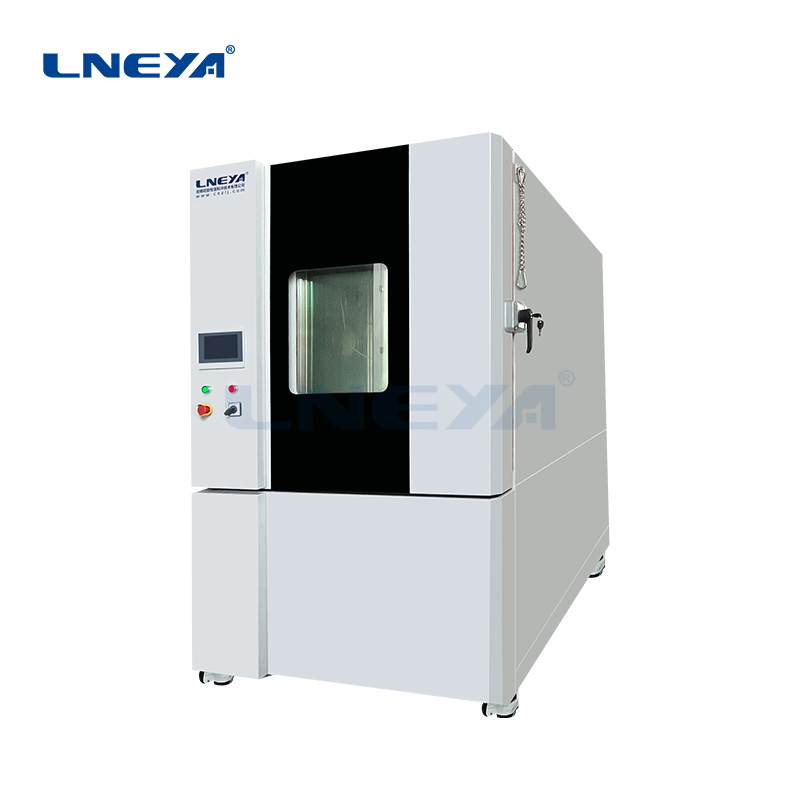

A test chamber, also called an Umweltprüfkammer or climate test chamber, looks similar to a refrigerator. Before testing, you place the sample inside the chamber and set the desired test parameters on the control panel, such as temperature, humidity, altitude, pressure, or vibration. Some chambers have transparent doors so engineers can observe the sample throughout the test and record changes.

Test chambers are essential for evaluating product performance and ensuring compliance with quality standards. This is especially critical in fields like aerospace, where safety and reliability are non-negotiable.

Types of Test Chambers

Test chambers can be categorized by the environment they simulate. Choosing the right type ensures accurate and meaningful testing results. Here are seven common types of test chambers and their functions, testing purposes, and applications.

Temperature and Humidity Chambers

Temperature and humidity chambers control both temperature and moisture inside the chamber. They can maintain fixed conditions or follow pre-set temperature and humidity profiles. These chambers test how samples perform under different climate conditions and help evaluate stability and lifespan.

Electronics, packaging materials, and plastics are commonly tested in these chambers to ensure they withstand environmental stress over time.

Thermal Shock Chambers

Thermal shock chambers expose samples to rapid temperature changes. These chambers usually have two compartments, one hot and one cold. Samples are placed in a basket and quickly moved between the two zones according to a set cycle.

The purpose is to simulate extreme conditions. For instance, a car might leave a warm garage in winter and be exposed to -20°C outside. Or spacecraft components may experience even harsher thermal shocks. Testing at this stage helps reveal material defects before products are used in the field.

Altitude Chambers

Altitude chambers, sometimes called low-pressure chambers, simulate high-altitude environments where air pressure is low. By reducing pressure inside the chamber, engineers can mimic mountain peaks or flight conditions. These chambers are widely used in aerospace and aviation.

They help researchers identify pressure-related failures during the design phase and ensure that products operate safely under low-pressure conditions.

Salt Spray Chambers

Salt spray chambers create a corrosive environment to test metals, coatings, or protective layers. These chambers are common in factories producing automotive parts, construction materials, and marine equipment. Engineers control exposure cycles and monitor corrosion development throughout the test. This helps evaluate the material’s durability in harsh chemical conditions.

Vibration Test Chambers

Vibration test chambers apply mechanical stress while controlling temperature and humidity. They help identify potential structural looseness or failures caused by vibration during operation or transportation.

This testing is widely used in electronics and automotive component manufacturing. Engineers can observe how products react to combined environmental and mechanical stress.

Drive-In and Walk-In Chambers

Drive-in and walk-in chambers are large environmental testing units. Their size allows testing full vehicles, machinery, or multiple large components simultaneously. They can simulate temperature, humidity, and combined stresses to evaluate how all parts of a product interact under specific conditions. These chambers are common in automotive, aerospace, and industrial testing.

Vacuum Ovens

Vacuum ovens create low-pressure environments by removing air or moisture. They are used for drying, curing, or testing materials sensitive to oxygen or humidity, such as electronic components, medical devices, and composites.

Engineers can monitor thermal decomposition, curing time, and material stability without interference from air or moisture. These ovens are essential for precise thermal processes in both laboratory and production settings.

Schlussfolgerung

Test chambers do not all serve the same purpose. Each type has its unique function. Choosing the right chamber depends on your testing needs. LNEYA provides a variety of climate test chambers, including temperature and humidity chambers, walk-in chambers, thermal cycling chambers, and thermal shock chambers.

If you are unsure which one is right for your application, our test chamber experts offer free advice to help you select the best solution.

- Chiller Components and Refrigeration Fundamentals Guides

- Chiller Types and Selection Guides

- How Does a Peltier Cooler Work

- Peltier Chiller vs. Compressor Chiller

- What Is a Peltier Chiller

- OEM vs Aftermarket Chiller Spare Parts

- Chiller Surge

- Chiller Cooling Capacity Units

- Dezember 2025

- November 2025

- Oktober 2025

- September 2025

- August 2025

- Juli 2025

- Juni 2025

- Mai 2025

- März 2025

- Februar 2025

- Januar 2025

- Dezember 2024

- November 2024

- Oktober 2024

- September 2024

- August 2024

- Juli 2024

- Juni 2024

- Mai 2024

- April 2024

- März 2024

- Februar 2024

- September 2023

- Juli 2023

- Juni 2023

- Mai 2023

- Januar 2023

luftgekühlte Kältemaschine Kühler Installation der Kältemaschine Wartung von Kühlanlagen chiller refrigerant Kältemaschinen Kalte Montage Gefrierschrank Kaltwassersatz Kühl-Heizsystem cooling system dynamisches Temperaturkontrollsystem energieeffizienter Chiller explosionsgeschützter Kühler Gefrierschrank Heizungsumwälzpumpe Industriekühler Industriekälteanlagen Industriekühlung industrieller Gefrierschrank Industriekühlschrank Mantelreaktor Laborkühlschrank Niedertemperaturkühler Nachrichten Ölkühler Prozesskühler process cooling Reaktorkühler Reaktorkühlung Reaktorkühlung Heizung Reaktorheizung Kühlung Kältethermostat Schneckenkühler Halbleiter-Kühlgerät Halbleiter-Testkühler sundi tcu Temperaturkontrolle Prüfkammer Thermostat Ultra-Niedertemperatur-Kühler Fahrzeug-Test-Kühler Kaltwassersatz wassergekühlte Kältemaschine

Verwandte Chiller

KONTAKT US

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

Haben Sie eine Frage oder benötigen Sie ein Angebot? Füllen Sie das untenstehende Formular aus, und unser Team wird sich innerhalb von 24 Stunden bei Ihnen melden.

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant