Wofür werden Chiller verwendet

Wofür werden Chiller verwendet? Die kurze Antwort: Sie verhindern, dass Maschinen und Prozesse überhitzen. Nach jahrelanger Arbeit mit industriellen Kühlsystemen haben Sie vielleicht gesehen, wie Chiller millionenschwere Produktionsläufe retten, MRT-Geräte durch Nachtschichten zuverlässig betreiben und sogar sicherstellen, dass Limonadenflaschen die Linie bei genau der richtigen Temperatur verlassen.

Ein Chiller entzieht einem Prozess Wärme, führt sie durch einen Kühlzyklus und gibt sie an Luft oder Wasser ab. In der Praxis ist er das Rückgrat vieler Industrien. Ohne diese konstante Temperaturkontrolle würde der gesamte Betrieb zum Stillstand kommen.

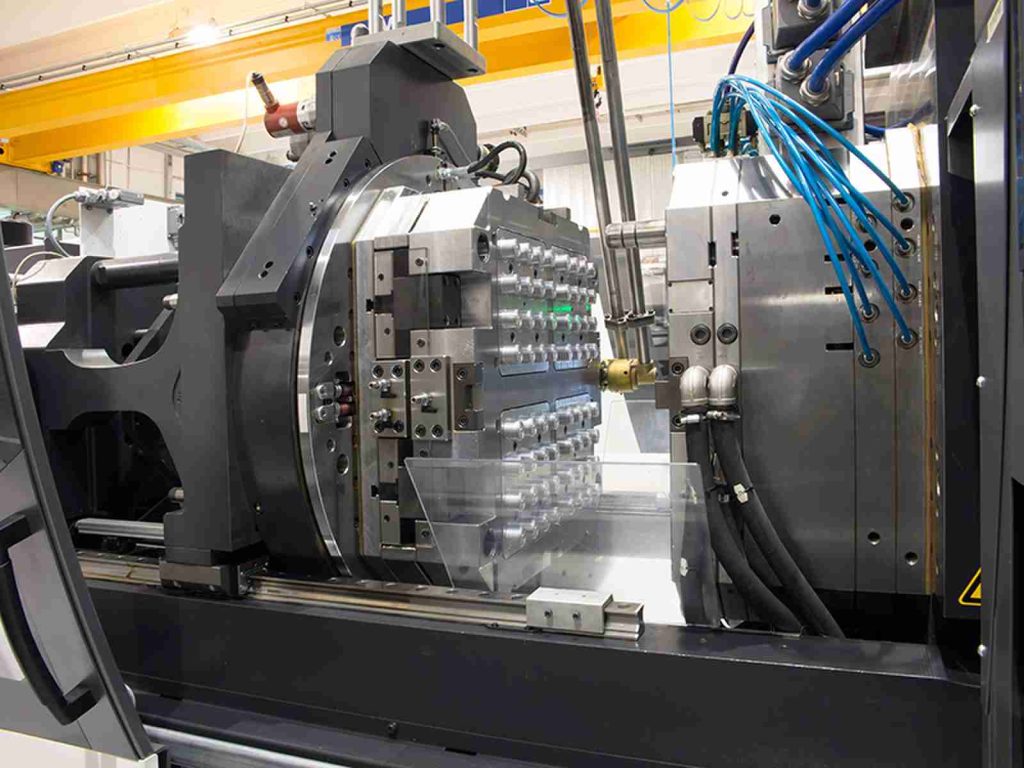

Kunststoff- und Spritzgussverfahren

Wenn Sie schon einmal beobachtet haben, dass eine Form zu früh öffnet, kennen Sie den Ärger. Teile kleben, Kanten verziehen sich, Zyklen verlangsamen sich. Die Kühlung bestimmt die Form jedes Kunststoffteils. Durch die konstante Temperaturhaltung der Form sorgt ein wassergekühlter Chiller für gleichbleibende Abmessungen und reduziert Ausschuss. Auf einer stark frequentierten Werkstattfläche bedeutet schnelleres Formen-Kühlen nicht nur bessere Qualität, sondern auch mehr Teile pro Stunde.

Halbleiter- und Elektronikfertigung

Mikrochips verzeihen keine Fehler. Schon wenige Grad Abweichung während der Lithografie können ganze Wafer ruinieren. Deshalb betreiben Fertigungen Halbleiter-Chiller mit redundanten Pumpen, Backup-Steuerungen und Sensoren überall.

Wenn Sie Wafer-Ätzer oder Teststationen im Millionenwert kühlen, machen die Ausfallkosten den Chiller günstig erscheinen. Hier geht es bei der präzisen Kühlung weniger um Komfort als darum, empfindliche Schaltungen zu schützen, die die Geräte antreiben.

Chemische und pharmazeutische Produktion

Zu viel Wärme und Sie erhalten Nebenprodukte, die niemand wollte. Zu wenig und die Ausbeuten leiden. Chemische Chiller stabilisieren Reaktoren, Kondensatoren und sogar Lagertanks, sodass Chemiker innerhalb sicherer, vorhersehbarer Fenster arbeiten können.

In der Pharmaindustrie kommt eine weitere Ebene hinzu: Compliance. Regulierungsbehörden möchten Nachweise, dass jede Charge unter kontrollierten Bedingungen hergestellt wurde. Eine zuverlässige Chiller-Schleife ist Teil dieses Nachweises, und ohne sie verlieren Sie nicht nur eine Charge – Sie riskieren die Zulassung.

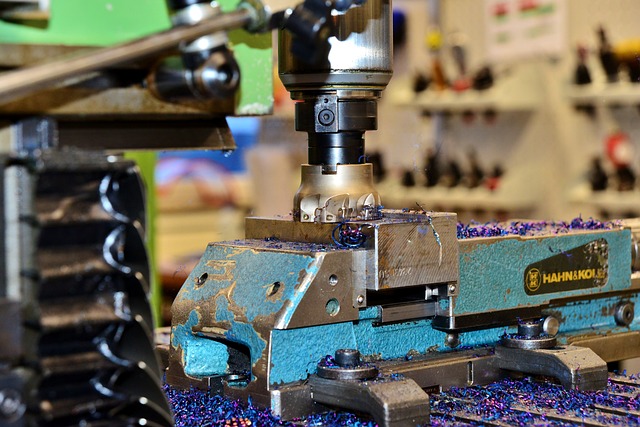

Metallverarbeitung und Zerspanung

Beim Zerspanen schleicht sich die Wärme unbemerkt ein. Spindeln erwärmen sich, Schneidöl wird dünner, und Toleranzen verschieben sich. Plötzlich entspricht das Luft- und Raumfahrtteil, das im Mikrometerbereich gemessen werden sollte, nicht mehr den Spezifikationen.

Ein Prozesskühl-Chiller hält CNC-Maschinen, Schleifmaschinen und Schneidflüssigkeiten im Griff. In hochpräzisen Werkstätten verfolgten Kunden stundenlang thermische Abweichungen. Am Ende erkannten sie, dass das Problem nicht das Werkzeug war, sondern das Fehlen stabiler Kühlung.

Medizinische Bildgebungsgeräte

Haben Sie sich schon einmal gefragt, warum ein MRT stundenlang ohne Unterbrechung läuft? Im Hintergrund zieht ein spezieller medizinischer Chiller die Wärme von Magneten und Elektronik ab. Wenn die Kühlung versagt, werden Scans unterbrochen, Patienten warten, und Krankenhäuser verlieren sowohl Einnahmen als auch Vertrauen.

Laborprozesse

Labore wirken ruhig, aber die Geräte sind es nicht. Rotationsverdampfer, Spektrometer, Destillationsanlagen — sie alle erzeugen Wärme und benötigen präzise Kühlung. Ein kompakter Laborkühler erledigt die Arbeit ohne Vibrationen oder Geräusche, die die Ergebnisse verfälschen könnten.

Eine zerstörte Probe mag unbedeutend erscheinen, aber wenn diese Probe Wochen an Forschung repräsentiert, vergisst niemand, den Kühlkreislauf erneut zu überprüfen.

Reinräume und pharmazeutische Labore

Reinräume konzentrieren sich auf die Kontrolle von Luft, Partikeln, Feuchtigkeit und Temperatur. Chiller versorgen die Luftbehandler und Geräte, die diese Räume stabil halten.

Pharma-Labore betreiben oft redundante Kühlsysteme nebeneinander. Fällt eines aus, übernimmt das andere sofort. Das Risiko ist zu hoch für einen einzigen Ausfallpunkt, da ein instabiler Reinraum Millionen an verschwendeten Produkten kosten kann.

Abfüllung und Verpackung

Dieses kalte Bier oder Erfrischungsgetränk in Ihrem Kühlschrank? Ein Chiller hat es berührt, bevor Sie es taten. Das Kühlen von Flüssigkeiten vor der Abfüllung bewahrt den Geschmack und verlängert die Haltbarkeit.

Auf der Verpackungslinie erzeugen Siegel und Klebstoffe Wärme. Ohne Kühlung verziehen sich Verpackungen oder Dichtungen versagen. Ein zuverlässiger Chillerkreislauf hält den Prozess schnell, stabil und lebensmittelsicher.

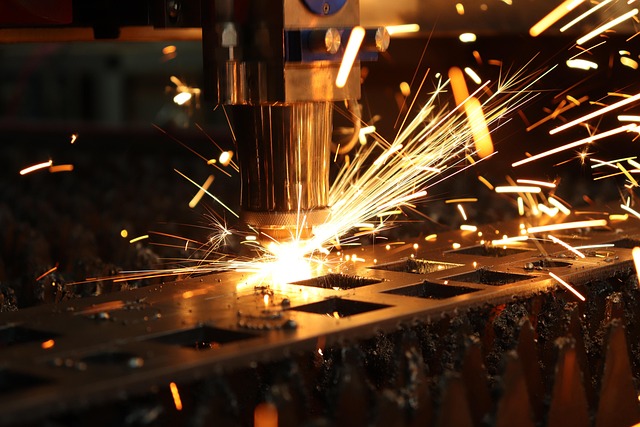

Laser- und Schweißgeräte

Laser und Schweißgeräte bringen enorme Energiemengen auf kleine Punkte. Optiken, Spiegel und Schweißbäder erhitzen sich schnell. Ein industrieller Chiller hält die Ausrichtung präzise und die Schweißqualität konstant.

Wir haben Werkstätten gesehen, in denen das Überspringen der richtigen Kühlung zu ständiger Nacharbeit führte. Mit dem richtigen Prozesskühler bleiben die Maschinen stabil, und die Bediener verbringen weniger Zeit mit Problemlösungen.

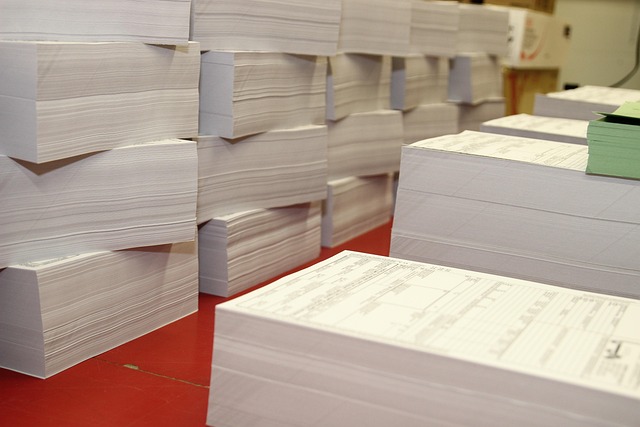

Druckindustrie

Lange Druckläufe erhitzen Walzen, Farbe und sogar Papier. Dann sieht man verschmierte Tinte oder gewellte Blätter. Chiller stabilisieren das System, sodass der erste Druck dem letzten entspricht.

In wettbewerbsfähigen Druckereien ist die Betriebszeit alles. Ein Druck-Chiller sorgt dafür, dass Deadlines eingehalten werden und der Abfall gering bleibt.

Suchen Sie einen neuen Chiller oder rüsten Sie Ihre alte Anlage auf?

Wenn Sie Optionen für Ihre Anlage, Ihr Labor oder Ihre Einrichtung abwägen, betrachten Sie den Chiller nicht als Nebensache. Das richtige System zahlt sich durch weniger Ausfälle und niedrigere Energiekosten aus.

Suchen Sie einen neuen Chiller oder planen Sie, Ihre alte Anlage aufzurüsten? Kontaktieren Sie uns! Wir gehen Ihren Prozess gemeinsam durch und finden ein System, das passt.

- Chiller Components and Refrigeration Fundamentals Guides

- Chiller Types and Selection Guides

- How Does a Peltier Cooler Work

- Peltier Chiller vs. Compressor Chiller

- What Is a Peltier Chiller

- OEM vs Aftermarket Chiller Spare Parts

- Chiller Surge

- Chiller Cooling Capacity Units

- Dezember 2025

- November 2025

- Oktober 2025

- September 2025

- August 2025

- Juli 2025

- Juni 2025

- Mai 2025

- März 2025

- Februar 2025

- Januar 2025

- Dezember 2024

- November 2024

- Oktober 2024

- September 2024

- August 2024

- Juli 2024

- Juni 2024

- Mai 2024

- April 2024

- März 2024

- Februar 2024

- September 2023

- Juli 2023

- Juni 2023

- Mai 2023

- Januar 2023

luftgekühlte Kältemaschine Kühler Wartung von Kühlanlagen Kältemaschinen Kalte Montage Gefrierschrank Kaltwassersatz dynamisches Temperaturkontrollsystem energieeffizienter Chiller Heizungsumwälzpumpe Industriekühler Industriekälteanlagen Industriekühlung industrieller Gefrierschrank Industriekühlschrank Mantelreaktor Laborkühlschrank Niedertemperaturkühler Nachrichten Prozesskühler process cooling Reaktorkühlung Reaktorheizung Kühlung Kältethermostat Schneckenkühler Halbleiter-Kühlgerät Halbleiter-Testkühler sundi tcu Temperaturkontrolle Prüfkammer Thermostat Ultra-Niedertemperatur-Kühler Fahrzeug-Test-Kühler Kaltwassersatz wassergekühlte Kältemaschine

Verwandte Chiller

KONTAKT US

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

Haben Sie eine Frage oder benötigen Sie ein Angebot? Füllen Sie das untenstehende Formular aus, und unser Team wird sich innerhalb von 24 Stunden bei Ihnen melden.

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant