What Does a 200 Ton Chiller Cost

A 200-ton chiller is a major investment, whether it is used for HVAC cooling, industrial processes, or large manufacturing lines. Buyers typically want a clear answer to one question: how much does a 200 ton chiller cost?

The truth is that pricing varies widely depending on the type of chiller, its configuration, and the application. This guide breaks down real cost ranges, explains what drives those differences, and help you understand what you should realistically budget for.

Price Breakdown by Chiller Type

1.How Much Does a 200 Ton Air-Cooled Chiller Cost?

A 200 ton air-cooled chiller typically costs more upfront, with prices ranging from USD 90,000 to USD 150,000 depending on efficiency, brand, and configuration.

The higher chiller price comes from its integrated condenser system, larger footprint, and reduced installation requirements.

Their cost is largely driven by the size of the condenser coils, the number of fans, and whether the system uses fixed-speed or variable-speed compressors.

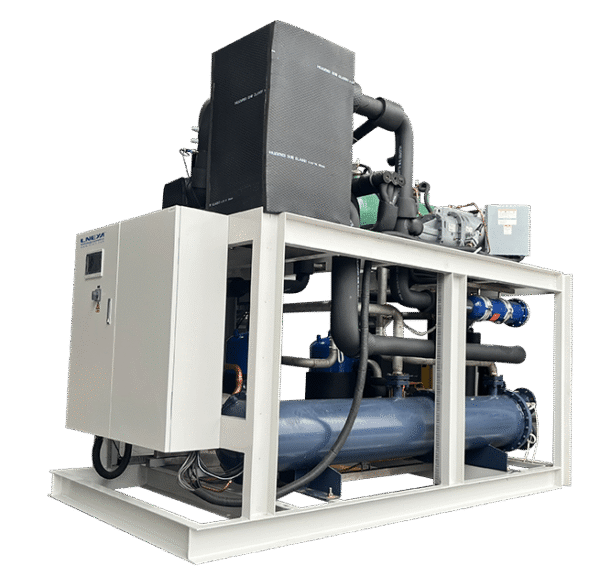

2.How Much Does a 200 Ton Water-Cooled Chiller Cost?

A 200 ton water-cooled chiller generally ranges from USD 70,000 to USD 120,000, making it slightly less expensive than air-cooled units in terms of equipment cost. However, the total system price can be higher once cooling towers, pumps, and piping are included.

The chiller cost is influenced by the evaporator type, compressor technology, and whether the chiller will run in a central plant configuration.

3.How Much Does a 200 Ton High-Precision Industrial Chiller Cost?

A 200 ton high-precision industrial chiller can cost between USD 130,000 and USD 220,000, depending on the required temperature stability and materials.

The higher chiller price reflects features such as stainless-steel piping, corrosion-resistant heat exchangers, variable-speed pumping systems, and advanced PLC logic. These designs are intended to achieve precise control, typically with an accuracy of ±0.1°C or higher.

4.How Much Do 200 Ton Modular / Multi-Compressor Systems Cost?

Modular or multi-compressor 200-ton chillers generally cost USD 140,000 to USD 250,000, depending on the number of modules and redundancy required. These are the most expensive among 200 ton chiller types.

Modular chillers are designed for facilities that cannot afford downtime. Instead of a single large compressor, they use multiple smaller compressors or modules that operate independently.

Their price also reflects the additional controls and piping needed to coordinate the modules.

What Determines the Price of a 200 Ton Chiller?

The cost of a 200 ton chiller varies because each system is designed around specific requirements. Several technical and practical factors influence the final chiller price.

1.Compressor Type

Screw compressors are more expensive but offer higher stability and longer life. Scroll compressors are cheaper but suited for lighter-duty applications. Inverter or variable-speed compressors typically increase chiller cost due to improved energy efficiency.

2.Heat Exchanger Material

Copper tubes, stainless steel plates, and titanium coils come with different price points. For corrosive or high-purity environments, the heat exchanger alone can add several thousand dollars to the total cost.

3.Kältemitteltyp

Low-GWP refrigerants and environmentally friendly options cost more. R134a, R410A, and R513A each affect performance and chiller price differently.

4.Controller & PLC System

Touchscreen PLCs, advanced diagnostics, and remote monitoring increase cost but improve long-term usability.

5.Pump Options

Fixed-speed pumps are cheaper. Variable-speed or high-lift industrial pumps increase the total chiller cost, especially in tall buildings or long-distance piping systems.

6.Ambient Temperature

High-temperature environments require oversized condensers or enhanced heat rejection designs, increasing the cost of a 200 ton chiller by several percent.

7.Customization Level

Anti-corrosion packages, explosion-proof designs, stainless-steel water circuits, and specialized coatings can raise the price significantly, especially in chemical or coastal regions.

Additional Costs You Should Expect

Beyond the equipment price, several project-related expenses influence the total 200 ton chiller cost.

How You Can Get an Accurate 200 Ton Chiller Quote?

To determine the exact 200 ton chiller cost for your application, suppliers will ask for key operating conditions. Providing accurate information ensures that the quote is neither over-designed nor under-capable.

Schlussfolgerung

Prices for 200-ton chillers vary significantly depending on the type and configuration. If you have specific requirements, LNEYA can provide you with a detailed quote.

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant