What Is a Spindle Chiller and How It Works

Precise cooling is crucial for maintaining the precision and performance of high-speed machinery. Spindle chillers are industrial cooling systems that ensure optimal temperatures are maintained in machinery, especially high-performance equipment like CNC machine tools.

The spindle, which secures the tool during machining, generates heat due to friction and high speed. Without proper cooling, this heat buildup can reduce equipment precision, increase wear, and lead to machine failure.

This article explains what a spindle chiller is, how it works, and its applications.

What Is a Spindle Chiller?

A spindle chiller is a specialized cooling system designed to regulate the temperature of the spindle in CNC machines and other high-speed machinery. The spindle is a critical component in any machine tool, as it houses the rotating tool that performs the machining operations.

If the spindle overheats, it can lead to reduced performance, inaccuracies, and even long-term damage to the machine. Spindle chillers help to keep the temperature of the spindle within optimal operating limits, ensuring smooth operation and preventing damage caused by heat buildup.

How Does a Spindle Chiller Work?

Spindle chillers operate using a closed-loop cooling system. This system circulates a coolant (usually water or a water-based coolant) through the spindle to absorb the heat generated during high-speed cutting or machining processes.

As the coolant flows through the spindle, it absorbs the excess heat and carries it away from the spindle. This heated coolant is then passed through a cooling unit, where it is cooled down, before being recirculated back into the spindle to continue the cooling process.

In simple terms, the chiller acts like a temperature regulator for the spindle, ensuring it never gets too hot. The coolant absorbs the heat produced by friction and high-speed operations, preventing thermal expansion, loss of accuracy, and premature wear.

Benefits of Using a Spindle Chiller

Prevent Overheating

One of the primary functions of a spindle chiller is to prevent the spindle from overheating. As the spindle rotates at high speeds, friction generates heat. If this heat isn’t effectively dissipated, it can cause the spindle to expand and lose its accuracy.

A spindle chiller ensures that the temperature remains within safe limits, allowing the spindle to perform at its best without the risk of overheating. Preventing overheating also extends the lifespan of the spindle and other critical components.

Improved Precision and Efficiency

Temperature fluctuations can lead to thermal expansion, which can cause the spindle and other machine parts to shift or distort. This affects the precision of the machining process, leading to inaccurate cuts and poor-quality workpieces.

By maintaining a consistent temperature, a spindle chiller ensures that the spindle stays within its optimal operating range, helping to maintain the precision of the machining process. This not only improves the quality of the work but also increases the efficiency of the entire operation by reducing errors and the need for rework.

Increased Tool Life

Heat not only affects the spindle but also the cutting tools. High temperatures can cause the cutting edge of tools to wear out faster, reducing their lifespan and increasing the frequency of tool changes.

By keeping the spindle cool, a spindle chiller also helps to keep the cutting tools at a more stable temperature, reducing the risk of premature wear. This can significantly lower tool replacement costs and improve the overall cost-effectiveness of the machining process.

Applications of Spindle Chillers

Spindle chillers are widely used across various industries where high precision and high-speed operations are required. Let’s take a closer look at some of the industries that benefit from using spindle chillers:

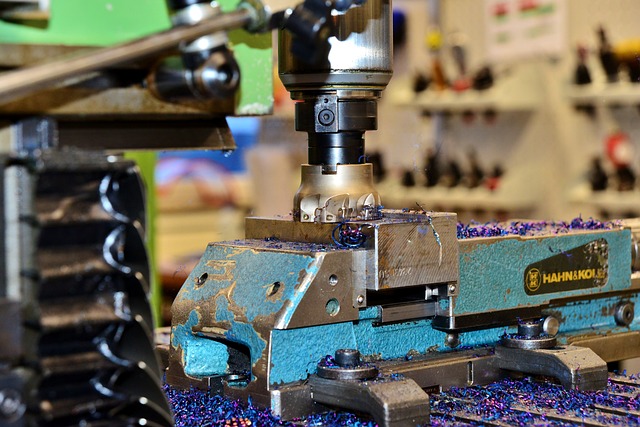

CNC Machining

In CNC machining, the spindle is the most critical component, as it holds the cutting tool and rotates it at high speeds. Spindle chillers are commonly used to keep the spindle cool during these operations, ensuring that the machine can work with high precision and speed without overheating.

This is especially important in industries like aerospace and automotive, where tight tolerances and high-speed operations are a standard requirement.

Automobilfertigung

The automotive industry relies heavily on CNC machines for precision manufacturing of parts like engine components, transmission parts, and chassis elements. These machines operate at high speeds and require precise temperature control to maintain their performance.

Spindle chillers help maintain the accuracy of CNC machines in automotive manufacturing by preventing overheating, reducing wear, and improving overall efficiency.

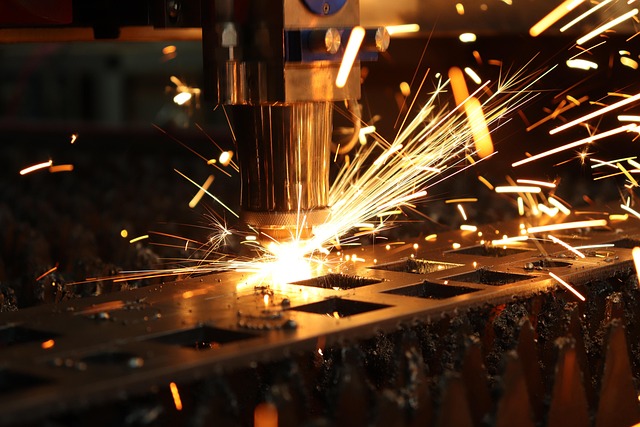

Luft- und Raumfahrt

In aerospace manufacturing, even the smallest error in machining can lead to catastrophic failures. High precision is essential when producing parts for aircraft and spacecraft. Spindle chillers help to maintain the accuracy and efficiency of CNC machines used in aerospace manufacturing by keeping the spindles at optimal temperatures, preventing distortion and ensuring high-quality parts.

Metalworking

Metalworking, especially high-precision processes like milling, drilling, and turning, requires stable temperatures to ensure that the machines produce high-quality parts.

Spindle chillers are used in metalworking to keep the spindles cool and prevent thermal expansion, which can affect the quality of the workpiece and the tool’s lifespan. They ensure that the process runs smoothly and efficiently, reducing the risk of defects.

Milling & Drilling

Milling and drilling are two of the most common machining processes that require high-speed spindles. These processes generate significant heat, which can negatively impact the performance and accuracy of the machine.

Spindle chillers are essential in milling and drilling applications, as they help maintain temperature control, improve precision, and increase the overall efficiency of the operation.

Schlussfolgerung

Spindle chillers are an essential part of high-speed machining operations, providing temperature control that helps prevent overheating, improve precision, and extend tool life.

Looking for a reliable spindle chiller? LNEYA offers luftgekühlt und water-cooled industrial cooling systems specifically designed for spindles, helping you precisely control heat in your process. Contact us to discuss your temperature control needs.

- Chiller Components and Refrigeration Fundamentals Guides

- Chiller Types and Selection Guides

- How Does a Peltier Cooler Work

- Peltier Chiller vs. Compressor Chiller

- What Is a Peltier Chiller

- OEM vs Aftermarket Chiller Spare Parts

- Chiller Surge

- Chiller Cooling Capacity Units

- Dezember 2025

- November 2025

- Oktober 2025

- September 2025

- August 2025

- Juli 2025

- Juni 2025

- Mai 2025

- März 2025

- Februar 2025

- Januar 2025

- Dezember 2024

- November 2024

- Oktober 2024

- September 2024

- August 2024

- Juli 2024

- Juni 2024

- Mai 2024

- April 2024

- März 2024

- Februar 2024

- September 2023

- Juli 2023

- Juni 2023

- Mai 2023

- Januar 2023

luftgekühlte Kältemaschine Kühler Installation der Kältemaschine Wartung von Kühlanlagen chiller refrigerant Kältemaschinen Kalte Montage Gefrierschrank Kaltwassersatz Kühl-Heizsystem cooling system dynamisches Temperaturkontrollsystem energieeffizienter Chiller explosionsgeschützter Kühler Gefrierschrank Heizungsumwälzpumpe Industriekühler Industriekälteanlagen Industriekühlung industrieller Gefrierschrank Industriekühlschrank Mantelreaktor Laborkühlschrank Niedertemperaturkühler Nachrichten Ölkühler Prozesskühler process cooling Reaktorkühler Reaktorkühlung Reaktorkühlung Heizung Reaktorheizung Kühlung Kältethermostat Schneckenkühler Halbleiter-Kühlgerät Halbleiter-Testkühler sundi tcu Temperaturkontrolle Prüfkammer Thermostat Ultra-Niedertemperatur-Kühler Fahrzeug-Test-Kühler Kaltwassersatz wassergekühlte Kältemaschine

Verwandte Chiller

KONTAKT US

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

Haben Sie eine Frage oder benötigen Sie ein Angebot? Füllen Sie das untenstehende Formular aus, und unser Team wird sich innerhalb von 24 Stunden bei Ihnen melden.

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant