How to avoid improper operation of heating and cooling circulator?

When the user runs the heating and cooling circulator, the operation needs to follow the instructions. Then, how to avoid unsuitable operation?

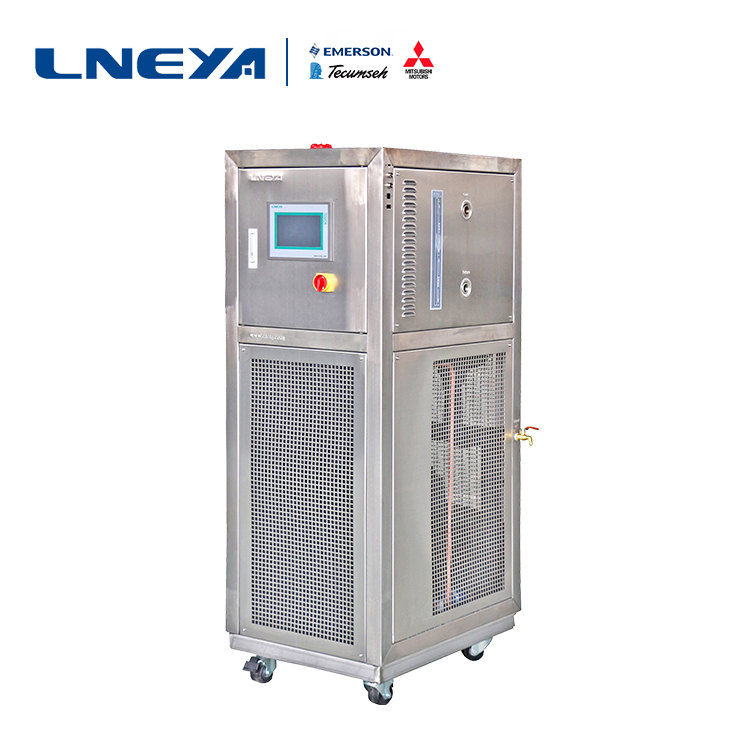

LNEYA heating and cooling circulator has multi-function alarm system and safety function. It uses plate heat exchanger and pipeline heater to increase heating and cooling rate. Large-screen touch screen graphic display, heating and cooling machine uses magnetic drive pump, no shaft seal leakage problem. Fully enclosed system, extending the life of the thermal fluid, a very wide temperature range, without the need to change the liquid medium.

Before the heating and cooling circulator is turned on, the inlet valve of the condenser on the unit that does not need to be opened is turned off to cause drowning, and a part of the cooling back water flows away from the condenser of the starting group, thereby reducing the cooling water in the condenser of the running unit. The flow rate causes the condensing pressure to rise. The operating current of the main unit increases. The cooling capacity of the unit is reduced, and the unit will be shut down seriously. It wastes electricity and reduces the cooling effect, and it is also easy to damage the equipment.

Due to the previous misoperation, the condensing pressure of the main engine and the temperature of the cooling water effluent rise, causing misjudgment to the operator. It is mistaken that the cooling water is not enough to open the condenser inlet valve and the cooling water pump outlet valve, and some also increase the cooling tower fan, resulting in increased power consumption of the pump and cooling tower fan. In addition, some users blindly added a cooling water pump. Although the addition of the cooling water pump can indeed reduce the cooling water temperature and the condensing pressure, after all, the power of one pump is wasted, so it is wrong.

The correct operation method of the heating and cooling circulator is that the unit condenser inlet valve is not required to be closed before starting to prevent drowning. Opening the heating and cooling unit will run the inlet and outlet valves on the unit condenser (the general outlet valve is normally open, the inlet valve is opened and closed as needed, and the condenser and evaporator are the same) to open the corresponding cooling water pump. Adjust the inlet and outlet pressure of the condenser to about 68.6 kPa (0.7 kg/cm). If the condenser inlet and outlet pressure gauges are swung too far, the cooling water system has air. The air should be vented until the pressure gauge indicates normal and continue to the next step.

During the use, do not handle all kinds of faults yourself, and avoid secondary damage caused by improper handling.

Verwandte Empfehlungen

-

Wuxi Guanya: Schwerpunkt auf Forschung und Entwicklung von Kühl- und Heizungsanlagen als Beitrag zur Entwicklung neuer Energien

2179On October 17, 2018, the three-day API was held in Nanjing International Expo Center. The exhibition was crowded with people. Wuxi Guanya was a frequent visitor to the API. Wuxi Guanya Constant Temperature Refrigeration Technology Co., Ltd. (herei...

Details anzeigen -

The difference between a large refrigeration and heating circulator and a test chamber

14311. For the high temperature test under special circumstances, the high and low temperature test chamber may not meet the requirements. Generally speaking, the high temperature upper limit of the high and low temperature test box is 200 ℃, and its ...

Details anzeigen -

Was ist zu tun, wenn der Hochdruckalarm des Kühlers?

2015People must pay attention to the maintenance of large-scale temperature control equipment such as industrial water chiller. Sometimes it is normal to encounter high-pressure alarm. We must first find out the causes of high-pressure of the industri...

Details anzeigen -

Beschreibung des Drucks der Labor-Kühlmaschine

1539The laboratory-specific chiller is one of the more popular equipments in the mechanical equipment industry. For this reason, the relevant pressure instructions have been specially compiled to help you better understand the laboratory-specific chil...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant