Troubleshoot the main points of failure of the high and low temperature cooling system

When the industrial high and low temperature cooling system is in use, what is the general reason if the temperature cannot drop down? How should we deal with such failures?

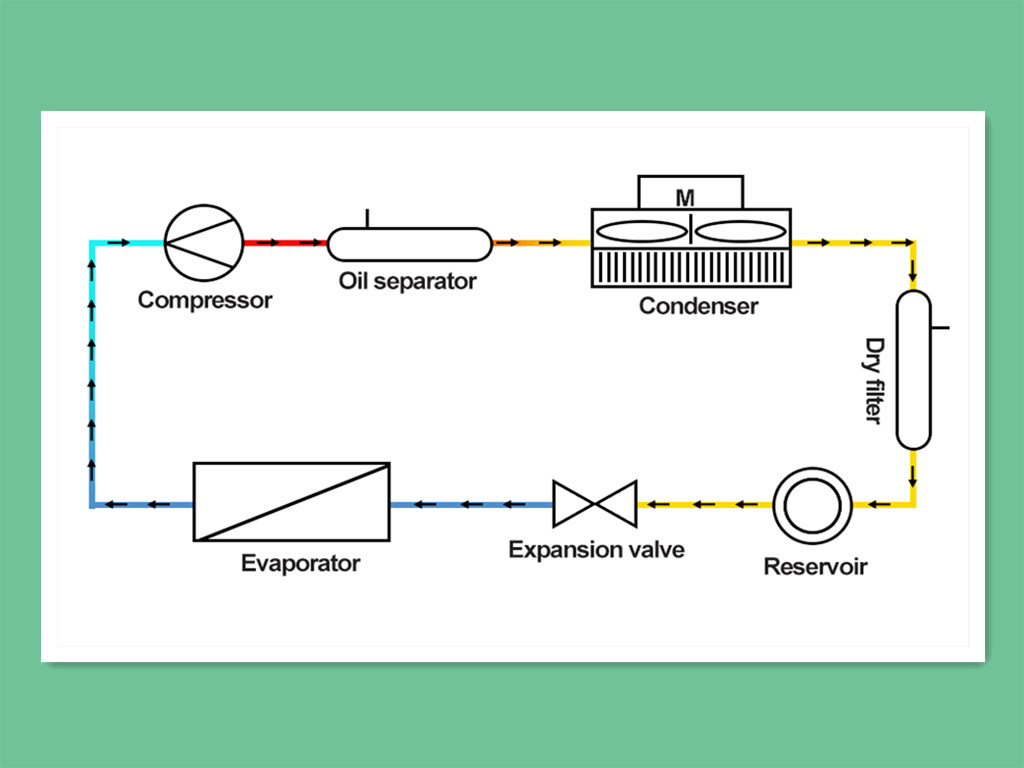

Let’s first analyze the principles and methods of industrial cooling. The circulating heat transfer medium is different. Generally, the high and low temperature cooling system industry mostly uses direct cooling, while indirect cooling is used, with plate heat exchangers or oil coolers installed inside. In other devices, the heat medium and cooling water source in the system exchange heat in the heat exchanger to reduce the temperature of the medium.

The temperature of the high and low temperature cooling system cannot be reduced. Generally, we conduct inspection and maintenance from the following aspects:

1. The cooling solenoid valve is damaged: it is necessary to check whether the solenoid valve coil can work normally, if it is damaged, it needs to be replaced; the panel does not output a cooling signal, carefully check the circuit or use the component replacement method to check.

2. Circuit failure: Check the circuit part of the system, the cooling water inlet or outlet pipeline is blocked: check whether the valve in the cooling water pipeline is fully opened, and ensure that the flow and pressure of the cooling water are sufficient, and the heating contactor is stuck, Always heating: observe the pull-in state of the contactor, and worsen damaged electrical parts.

In addition to troubleshooting the above two possible causes of failure, we also need to check whether the cooling plate is replaced or the cooling exchanger is blocked.

The advantage of using indirect cooling is that it has high temperature control accuracy and strong adaptability. It can be applied to the temperature control of high and low temperature cooling system industries. And because the heat transfer medium is cooled first, the cooling impact on the temperature control equipment is relatively small. Of course The disadvantage is that the cooling speed is relatively slow, and the price is more expensive than direct cooling.

Verwandte Empfehlungen

-

Vorteile von Labor-Niedertemperatur-Thermostaten

1280Der Labor-Niedertemperatur-Umwälzthermostat kann gleichzeitig konstante Temperatur und aktuelle Kühl-, Heiz- und Temperiergeräte bereitstellen. Die Labor-Niedertemperatur-Thermostat hat eine vernünftige Struktur, einfache Operati...

Details anzeigen -

Was ist die Funktion eines Hochtemperatur-Wärmeübertragungssystems??

1588Das Hochtemperatur-Wärmeträgerflüssigkeitssystem verfügt über ein vollständig geschlossenes Zirkulationssystem, so dass während des Hochtemperaturbetriebs kein Ölnebel entsteht und eine Hochtemperaturkühlung realisiert werden kann. Es ist die Temperaturregelung Ausrüstung u...

Details anzeigen -

Misunderstanding about the operation of the factory boiler

1436The boiler is a very common equipment in the factory. LNEYA Xiaobian tells everyone that many people have misunderstandings about it. Misunderstanding 1 The higher the steam pressure, the better. The choice of boiler steam pressure depends mainly ...

Details anzeigen -

How to choose a heating and cooling circulating water bath?

2127Heating and recirculating water bath In the process of selection, heating power, cooling power, pressure and flow are also factors that users need to consider. Good system design and accessory brand selection are related to the whole heating and c...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant