Compressor Inspection And Routine Maintenance Of Small Water Cooled Chillers

When people are hungry, they have to eat, and when the machine is broken, of course, it has to be repaired. In daily use, kleine wassergekühlte Kältemaschine requires regular maintenance and other operations. Today, I would like to share with you how to judge whether the compressors of small water cooled chillers are working properly and its daily maintenance methods.

1. Regularly check the operation status of the compressor equipment to check the exhaust gas temperature, especially when changing seasons. If the temperature difference is too large, it may affect the operation of the machine. If it is abnormally viewed in time, adjust the system condensation temperature and liquid supply status.

2. For small water cooled chiller equipment, it is also necessary to check the turbidity of the cooling water regularly and replace it if necessary.

3. Check whether the pump is working normally, check the running, dripping and leaking of the water supply system.

4. The refrigeration oil and filter of the chiller are replaced once every six months under normal conditions, depending on the usage.

Small water cooled chillers should be checked about the oil return of the compressor regularly in the later work, and keep it clean. When the oil level is reduced, it is necessary to replace the new oil in time to prevent the machine from being damaged due to poor lubrication.

Verwandte Empfehlungen

-

Umfassendes Testsystem für Automobilmotoren mit neuer Energie

1786When the LNEYA new energy vehicle motor integrated test system is running, the control panel settings are required. At the time of setting, if the user does not know how to use it, you can check the manual for use. The indicator of the new energy ...

Details anzeigen -

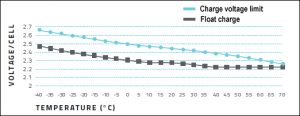

Is it right to extend battery life by lowering the ambient temperature?

1508The battery can work in a wide temperature range, but this does not allow the battery to be charged under high temperature conditions. The charging process is more delicate than the discharging process, and extreme care must be taken. Extreme cold...

Details anzeigen -

Changes in temperature control methods during semiconductor testing

1685As the use of semiconductor devices expands into new areas, such as automotive electronics, stricter requirements are imposed on their performance. Example: Devices are now required to operate at very low temperatures (about -40°C). To determine w...

Details anzeigen -

New energy vehicle quality test water cooling chiller simulation equipment

1426It is mainly used in the water cooling system stability test of new products such as electric drives, motors, reducers, and charging piles of new energy vehicles. Constant temperature, constant pressure and constant current heat test (5-85°C), h...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant