Why do special gases used in semiconductor manufacturing processes require chillers?

If you have any questions, please contact us

When using special gases in semiconductor manufacturing processes, a chiller is required, mainly due to the following reasons:

- Gas purity control: Special gases are used as raw materials in semiconductor manufacturing, and their purity is crucial to the performance of the final semiconductor device. Some special gases are prone to decomposition or react with impurities such as oxygen and water vapor at high temperatures, reducing their purity. The low-temperature environment provided by the chiller helps maintain the purity of gas during storage and transportation.

- Gas transportation and storage: Some special gases are easy to store in a liquefied state

Transportation, chillers can be used to cool gases to low temperatures, liquefy them, and facilitate storage and metering. Meanwhile, a low-temperature environment is beneficial for slowing down the natural evaporation rate of gases and reducing losses.

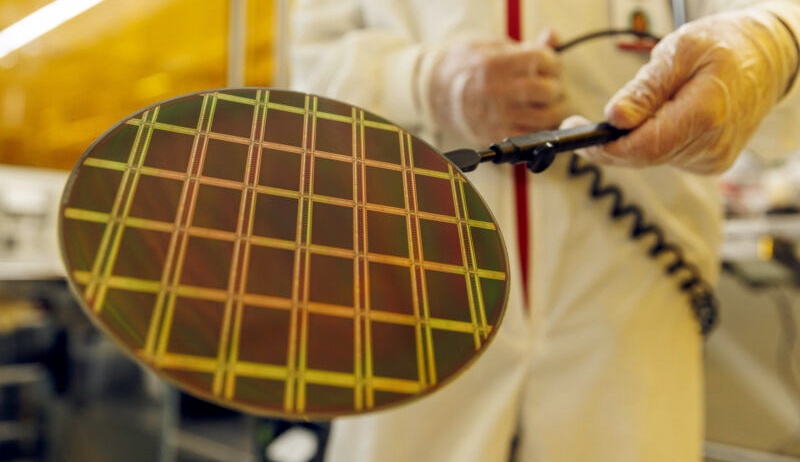

3. Process requirements: In semiconductor manufacturing processes such as chemical vapor deposition (CVD), physical vapor deposition (PVD), atomic layer deposition (ALD), etc., gas needs to go through a pre-treatment system, including a cooling system, before entering the reaction chamber to maintain gas transport at a specific temperature and prevent gas preheating or premature reaction in the pipeline.

4. Equipment cooling: Semiconductor production equipment generates a large amount of heat during operation, and requires a chiller to provide cooling for its internal gas delivery pipelines, reaction chambers, and other components to ensure that the gas maintains a stable temperature when entering and leaving the chamber. This is crucial for precise process control and product quality.

5. Safety considerations: Some special gases may become unstable or flammable and explosive at high temperatures. Using a chiller can reduce the risk of gas leakage accidents and ensure the safety of the entire process.

Therefore, the chiller is crucial for the storage, treatment, and use of special gases in the semiconductor manufacturing process, and is one of the key equipment to ensure the smooth progress of the semiconductor manufacturing process.

Request a quote

7 * 24 kostenlose Beratung und umfassende Lösungen anbieten

Verwandte Empfehlungen

-

Wie kann man das Expansionsventil eines Tiefkühlgeräts reparieren?

1793Der effektive Betrieb eines Tiefkühlgeräts hängt von der erforderlichen Kühlwirkung ab. Es ist wichtig, das Expansionsventil zu korrigieren, wenn eine bessere Kühlwirkung gewünscht wird. Wie kann man also das Expansionsventil eines Tiefkühlgeräts reparieren?Während ...

Details anzeigen -

Application of laboratory temperature control unit machines in the chemical industry

1606laboratory temperature control unit application

Details anzeigen -

Bedeutung von Kältemitteln in Batterietestsystemen für neue Energiefahrzeuge

1960Wenn die Durchflussmenge des Kältemittels im Testsystem für die neue Energiefahrzeugbatterie extrem gering ist, beginnt das Kältemittel, sich aus dem ersten dehnbaren Raum am hinteren Ende des Drosselventils auszudehnen. Der größte Teil der Ausdehnung am hinteren Ende der...

Details anzeigen -

Effect of High Precision Semiconductor Constant Temperature Series Evaporator on Refrigeration

1293The high-precision semiconductor constant temperature series of different models of the equipment, the choice of evaporation is also different, then, what effect does the heat exchanger have on the high-precision semiconductor constant temperature...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant

Zur Konsultation einreichen

Wir werden Ihnen innerhalb von 24 Stunden antworten