Routinewartung der Multireaktor-Temperiergeräte der tcu

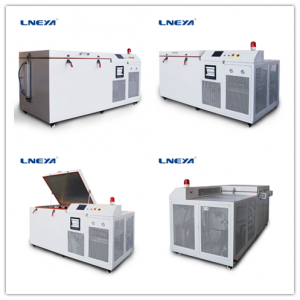

TCU multi-reactor temperature control equipment is widely used in research departments such as petroleum, chemical, electronic instruments, physics, chemistry, bioengineering, physical property testing and chemical analysis, colleges and universities, enterprise quality inspection and production departments to provide users with a liquid environment with controlled cold and hot, uniform and constant temperature when working.

1. Tcu multi-reactor temperature control equipment is a heating equipment that can control the temperature of the reaction material by heating the heat transfer oil in the jacket of the reactor to transfer heat energy to the material in the reactor indirectly.

2. The whole liquid circulation is a closed system. There is no absorption of water vapor at low temperature and no oil mist at high temperature. The heat transfer oil can work at a wide temperature; The same machine and the same heat conduction medium can realize continuous temperature rise and fall control.

3. Equipped with a heating and cooling integrated container, the heat exchange area is large, the heating and cooling rate is fast, and the demand for heat transfer oil is relatively small. It can realize continuous temperature rise and fall. Refrigeration heat exchanger adopts plate heat exchanger with high heat exchange efficiency and small floor area.

4. It has self-diagnosis function, refrigerator overload protection, high-voltage pressure switch, overload relay, thermal protection device and other reliable guarantee functions, fully ensuring reliable use;

5. In case of power failure, use dry compressed air regularly to clean the inside of the machine’s electric box and heat dissipation dust to avoid electrical failure caused by metal residues falling on the electrical components;

6. During normal use, use dry compressed air regularly to clean the metal residue and dust on the fan cover of the pump inside the machine to prevent the motor from radiating poorly after the fan cover is blocked, which may cause abnormal noise or jamming of the pump motor;

7. During long-term use, regularly maintain or replace other machine parts according to other requirements in the manual. In case of shutdown, regularly clean the filter at the oil return port of the machine to avoid over-temperature alarm and other faults caused by filter blockage; Customers can formulate effective maintenance plans according to the use of the machine and the site environment.

Verwandte Empfehlungen

-

Die Bedeutung der Auswahl eines Qualitätsherstellers von Kühlern

1226The first is professional operators.Professional refrigeration practitioners are the prerequisite for the maintenance, repair and maintenance of the chiller. If there are no professionals to work on the refrigeration equipment, it will not only c...

Details anzeigen -

Kühler für 200L Destillationskessel

1234Die Kältemaschine für 200L Destillationskessel muss zwei Hauptfunktionen gleichzeitig erfüllen: Eine ist es, Methanoldampf zu kondensieren, und die andere ist es, das Material während des Reaktionsprozesses zu kühlen. ...

Details anzeigen -

Instructions to Use Industrial Cryogenic Refrigerator

1778Industrial refrigerators are one of the cold water machines. It is classified according to the cooling mode of the cold water machine itself. It is divided into air cooling type refrigerators and water cooled refrigerators. Structural features: a ...

Details anzeigen -

Vocs Adsorptionsgeräte Kühlung Temperaturregelung Anweisungen

1634Mit der kontinuierlichen Verbesserung der Umweltschutzanforderungen hat sich jede Fabrik auch auf die Verarbeitung der in der Produktion erzeugten VCS-Gase konzentriert. LNEYA VCS-Adsorptionsanlagen können verschiedene VCS-Gase verarbeiten. Wie viel wissen Sie also...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant