The influence of the evaporator of the semiconductor thermostat on the refrigeration effect

Different models of semiconductor thermostat equipment have different options for evaporation.

According to different models, the choice of evaporator is different. For example, box-type semiconductor thermostat equipment uses water tank coil type evaporator; open semiconductor thermostat equipment and screw type semiconductor thermostat equipment use shell-and-tube evaporator ; For acid and alkali resistant semiconductor thermostat equipment, titanium tube evaporator or stainless steel plate exchanger can be selected. A kind of ice water machine, there are many choices, of course, can also be customized according to user needs.

The factors affecting the evaporation temperature of industrial semiconductor thermostat equipment are as follows:

There is oil in the evaporator pipeline. Under normal circumstances, because the lubricating oil and the refrigerant are mutually soluble, no oil film will be formed on the surface of the heat exchanger. The thermal resistance of the oil film may not be considered, but in the case of additional lubricating oil, the same label as the original one must be selected Lubricating oil to prevent the production of oil film.

The air filter is blocked, and the filter must be replaced regularly to ensure the circulating air volume required by the air conditioner. Dry filter clogged: In order to ensure the normal circulation of the refrigerating agent, the refrigeration system must be kept clean and dry. If the system has impurities, the dryer filter will be clogged and the system will be difficult to supply liquid, which will affect the cooling effect. Too little refrigerant, add refrigerant.

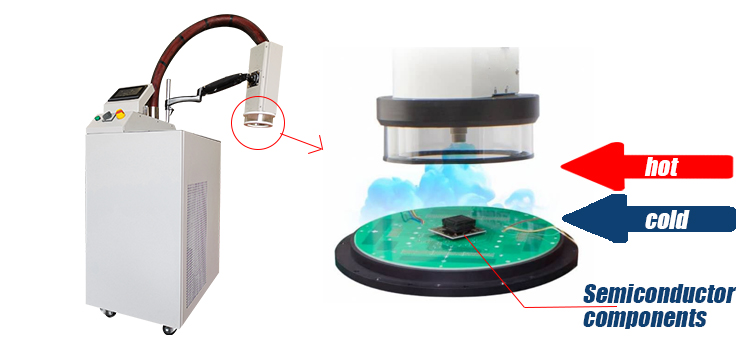

The temperature condition of the evaporator of the semiconductor constant temperature equipment. Under normal circumstances, the outer surface of the evaporator is very cold, and the condensed water drops continuously. The temperature of the inlet and outlet air is large. In abnormal conditions, the surface of the evaporator is not too cold and there is not much dew. , Or without condensation, the sound of refrigerant flowing is very loud, and the temperature difference between the inlet and outlet air is small. The reason is that the amount of refrigerant is insufficient, or the opening degree of the expansion valve is small.

The heat exchanger quality requirements of semiconductor thermostat equipment are very high. When choosing, users can also look at the quality and brand of their heat exchangers. It is recommended to choose a better one.

Verwandte Empfehlungen

-

Miniatur-Hochdruck-Reaktionskessel Kühlung Heizung Temperaturregelsystem

1553Das Miniatur-Hochdruck-Reaktionskessel-Kühl-Heiz-Temperaturregelsystem ist mit einer Gaszufuhreinheit, einer Flüssigkeitszufuhreinheit, einer Reaktionseinheit und einer Sammeleinheit ausgestattet. Das Rohmaterialgas und die Rohmaterialflüssigkeit werden gemischt und...

Details anzeigen -

Hersteller von Gefrierschränken bei -45 °C analysieren Methoden zur Erkennung und Reparatur von Kompressorausbrüchen

1444In the -45 ° C freezer, the compressor is one of the more important components, the manufacturer Wuxi Guanya (LNEYA) tells everyone that once the compressor fails, it needs timely inspection and maintenance, then how to check the work and maintena...

Details anzeigen -

Where can industrial heating circulators be useful?

1818The industrial heating circulator can provide a circulation device of cold source and heat source, and has a wide working range. It is used in the pharmaceutical, chemical, biological and other industries to provide heat and cold sources for reac...

Details anzeigen -

Was sind die Merkmale des Reaktorheizsystems?

1262Wuxi Guanya LNEYA Reaktorheizsystem Der Flüssigkeitsumlauf des gesamten Systems ist geschlossen, das System hat ein Ausdehnungsgefäß, das Ausdehnungsgefäß und der Flüssigkeitsumlauf sind adiabatisch, nehmen nicht am Flüssigkeitsumlauf teil, nur die...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant