Miniatur-Hochdruck-Reaktionskessel Kühlung Heizung Temperaturregelsystem

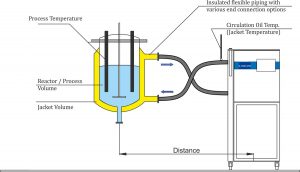

The miniature high-pressure reaction kettle refrigeration heating temperature control system is designed with a gas feed unit, a liquid feed unit, a reaction unit and a collection unit. The raw material gas and raw material liquid are mixed and preheated according to a certain ratio and enter the fixed bed reactor. The raw material gas is measured with the mass flow controller. The raw material liquid is measured by a metering pump. The reactor is heated by a three-stage electric heating furnace. The reaction product After coming out of the reaction unit, the gas-liquid separation is carried out first, the liquid material enters the liquid storage tank, and the tail gas is filtered and emptied or connected to the online analyzer.

The miniature high-pressure reaction kettle refrigeration heating temperature control system is a reaction kettle used in the laboratory for experiments, and is suitable for carrying out chemical and chemical reactions. It is necessary to simultaneously measure temperature, add inert gas, pressure, conductance, redox potential chemical synthesis reaction experiment. It is a type of production or experimental equipment that incorporates a reaction vessel, reaction condition control system, raw material feed, and product export system.

Temperature control is based on the temperature change of the thermal oil in the jacket of the miniature high-pressure reaction kettle cooling and heating temperature control system to control the temperature in the kettle body. slow. The liquid circulation of the entire system is closed. The system is equipped with an expansion vessel. The expansion vessel and the liquid circulation are adiabatic and do not participate in the liquid circulation. They are just mechanical connections. High temperature or low temperature, the medium in the expansion vessel is below 60 degrees.

The entire liquid circulation of the miniature high-pressure reaction kettle refrigeration heating temperature control system is a closed system. There is no water vapor absorption at low temperature, no oil mist is generated at high temperature, and the working temperature of the heat transfer oil is very wide; the same machine and the same heat transfer medium can be achieved -Temperature control from 100 degrees to 200 degrees.

Verwandte Empfehlungen

-

Das Kühlkreislaufsystem dient zum Auffangen des nicht kondensierbaren Abgases in der Destillation s

1570Die meisten Rektifikationstürme arbeiten mit einer zweistufigen Kondensation. In der ersten Stufe wird Kühlwasser verwendet, mit dem vor allem der Spitzendampf kondensiert wird, und in der zweiten Stufe wird Kaltwasser oder Ethylenglykol verwendet, das vor allem zur Aufbereitung des Abgases und zur Entfernung einer kleinen Menge...

Details anzeigen -

Die wichtigsten Punkte bei der Verwendung von Kryokühlschränken zur Kühlung von Reaktionen

1726The cryogenic refrigerator is also called chiller or cryogenic refrigeration circulator. It is an experimental instrument that can achieve low temperature -110 degrees refrigeration. This kind of equipment is often used in single-fluid refrigerati...

Details anzeigen -

For emergencies of the water-cooled chiller of the automatic temperature control system of the react

1346In the pharmaceutical and chemicalproduction, the automatic temperature control system of the reactor is widelyvisible. In order to ensure the safe production of the enterprise, what shouldusers pay attention to when facing unexpected situation...

Details anzeigen -

What is the connection between temperature and chemical reaction?

1346The chemical reaction can produce more stable products, and then as the temperature is released, the energy before the component reaction is released. On the other hand, the components of the reaction may produce different products, depending on t...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant