The Refrigeration Principle of Heating Cooling Circulator

Heating cooling circulator is the use of limited refrigerant in the closed refrigeration system, repeatedly refrigerant compression, condensation, expansion, evaporation, constantly in the evaporator heat absorption vaporization, cooling.

Die Heiz-Kühl-Umwälzpumpe is the circulation process that moves the heat from the low temperature object (such as the cold storage) to the high temperature object through the refrigerant, so as to cool the object below the ambient temperature and maintain the low temperature. This process is realized by the refrigeration device

The important parameter of the heating and cooling circulator is the coefficient of refrigeration, also known as the performance coefficient of the refrigeration unit, represented by the symbol COP. At a given ambient temperature, the lower the temperature of the cold storage, the smaller the coefficient of refrigeration.

The whole liquid cycle is closed, with the expansion vessel, the expansion vessel and the liquid cycle are insulated, do not participate in the liquid cycle, just mechanically connected, temperature the medium in the expansion vessel is less than 60 degrees no matter the liquid cycle temperature is high or low.

The whole liquid circulation is a closed system. At low temperature, there is no water vapor absorption, and at high temperature, there is no oil mist generation. Thermal oil has a wide range of operating temperature. No mechanical or electronic valves are used throughout the system.

Analysis of refrigeration principle

01.Compressed air refrigeration cycle

Due to the air constant temperature heating and constant temperature exhaust heat is not easy to achieve, so it can not run by the reverse cycle. In the compressed air refrigeration cycle, two constant pressure processes are used to replace the two constant temperature processes of the reverse cycle, so it can be regarded as the reverse cycle. In engineering applications, the compressor may be either piston or impeller type.

02.Compressed vapor refrigeration cycle

The reverse refrigeration cycle of compressed steam can be achieved in theory, but it will appear that the dry state is too low, which is not a positive factor for two-phase material compression. In order to avoid adverse factors, increase the refrigeration efficiency and simplify the equipment, in practical applications often use throttle valve (or expansion valve) to replace the expander.

Verwandte Empfehlungen

-

Wie erdet man den Testfahrer für die Batterie eines Elektrofahrzeugs?

1583The electric vehicle battery test is in the running state, and it is necessary to understand the operation of the accessories, and the drive and other accessories are in operation. If the electric vehicle battery test is not isolated between the A...

Details anzeigen -

Welches sind die üblichen Anschlussmethoden für industrielle Kältemaschinen?

1630There are several connection methods for industrial chillers, which are suitable for pipe connection under different conditions. First, welding connectionWelding is the most important and widely used connection method in pipeline engineering. Weld...

Details anzeigen -

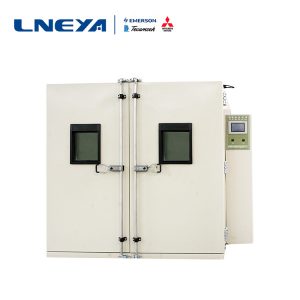

Beschreibung der Merkmale der begehbaren LNEYA-Prüfkammer

1321Einzigartige ausgewogene Temperaturregelung Methode, eine stabile und ausgewogene Heizleistung kann für eine hohe Präzision und hohe stabile Temperaturregelung verwendet werden.Die Temperatur, die von der Temperaturanzeige angezeigt wird,...

Details anzeigen -

Thermostatisches Bad SC der Firma Lneya refrigeration

2099Thermostatisches Bad von Lneya Kühlung Unternehmen ist weit verbreitet für die Trocknung, Destillation, Konzentration, Tauchen in chemischen Reagenzien, pharmazeutische und biologische Produkte verwendet werden, und kann auch für thermostatische Bad Heizung und andere...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant