What should do if the equipment of the thermal shock test chamber does not reach the set temperature

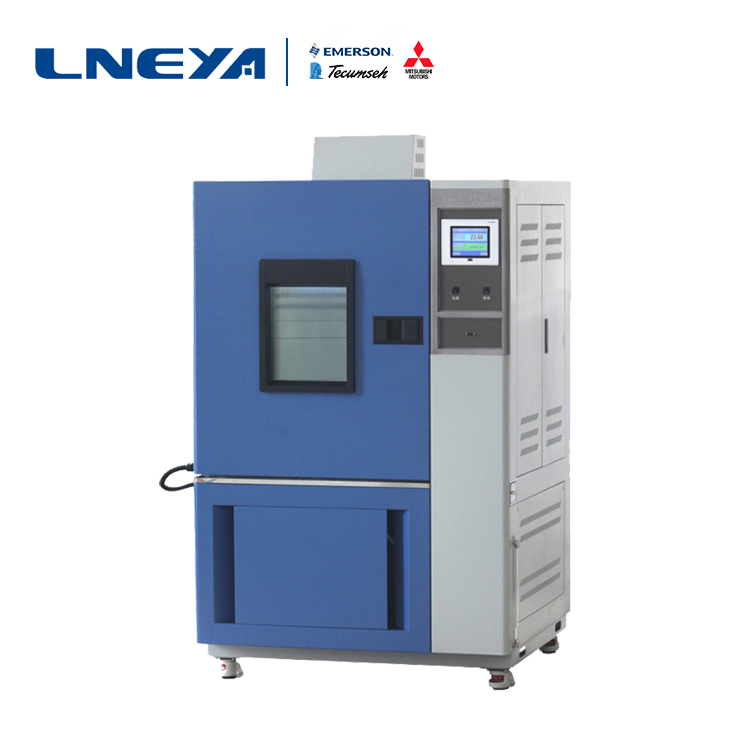

The choice of the manufacturer of the thermal shock test chamber is related to the quality of the thermal shock test chamber. Once the quality is set, the temperature setting of the equipment will not be closed. What should I do if I encounter the temperature setting problem?

The temperature set by the thermal shock test chamber is not up to the possibility that the heat exchange humidification tube is broken. You can either repair the factory or replace the new thermal shock test chamber directly. In the high temperature test, if the temperature does not change. When testing the temperature value, the electrical system can be inspected to eliminate the fault one by one, or the temperature probe may be broken, causing the device to not work when the water temperature is lower than the set standard temperature or 37 degrees.

The temperature and temperature of the thermal shock test chamber is too long or the heating tube is aging and damaged. When the actual water temperature is far below 37 degrees, the equipment has not worked, or the work is not working. If the temperature rises directly to cause over-temperature protection, the controller fails and the control instrument must be replaced. If the temperature is too high, you need to set the PID setting parameters first.

If the temperature rises very slowly, it is necessary to check the air circulation system to see if the regulating baffle of the air circulation is normally turned on. If the temperature of the thermal shock test box rises very quickly, check whether the motor of the air circulation is running normally. Because there is a time limit for use, so the running time is too long, it is inevitable that there will be some kinds of various faults, usually pay attention to regular maintenance and maintenance, generally can be largely avoided. If you encounter a large technical problem, you should seek solutions in time with the manufacturer.

LNEYA thermal shock test box manufacturer is a professional hot and cold impact test box manufacturer integrating R&D, production and sales. It has more than ten years of experience in refrigeration and heating equipment production, and has reached cooperation with many domestic enterprises.

Verwandte Empfehlungen

-

Effect of High Precision Semiconductor Constant Temperature Series Evaporator on Refrigeration

859The high-precision semiconductor constant temperature series of different models of the equipment, the choice of evaporation is also different, then, what effect does the heat exchanger have on the high-precision semiconductor constant temperature...

Details anzeigen -

Hauptpunkte der Wartung der LNEYA-Ultraniedrigtemperatur-Kälteumwälzpumpe

1087Ultra-low temperature refrigeration circulators need to be maintained after a long period of operation, so what aspects should be paid attention to? Check and maintain the ultra-low temperature refrigeration circulator on time. It can find problem...

Details anzeigen -

Feiern Sie den Neujahrstag und begrüßen Sie das neue Jahr

1278When the bells echo in the clear night sky,When the calendar turns to a new page,We are about to usher in a new year.Thanks for this year's harvestLet us have precious experience on our growthThere is always a reward for sweatThis yearWe sh...

Details anzeigen -

Das Prinzip und die Anwendung des Produktionskühlungsprozesses in der Pharmatechnik

1285Pharmazeutische Technik bezieht sich auf die Nutzung der Chemie. Der technische Prozess der Umwandlung von Rohstoffen in Arzneimittel durch eine Reihe von Produktionsprozessen unter Verwendung wissenschaftlicher Erkenntnisse und technologischer Mittel wie Biologie und Physiologie...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant