Routinewartungspunkte von speziellen Kühlgeräten für Laborgeräte

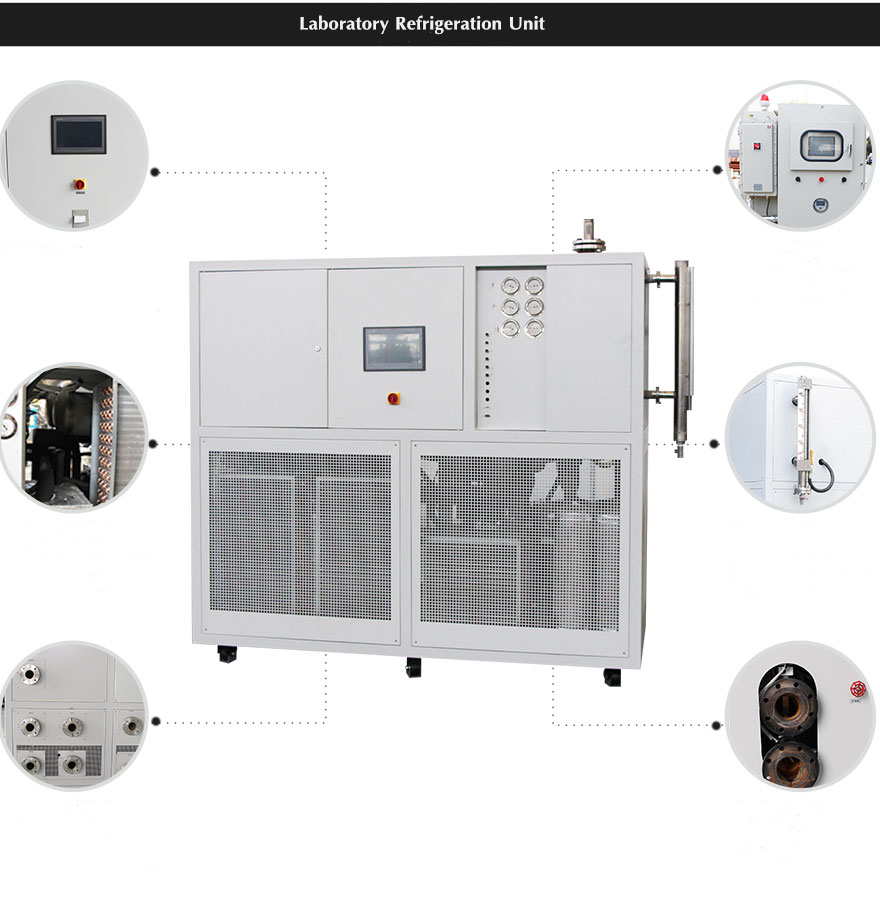

Industrial refrigeration units dedicated to laboratory instruments are used more in the pharmaceutical and chemical industries, and care must be taken when using them.

The daily maintenance of the industrial refrigeration unit dedicated to experimental instruments is mainly reflected in the following aspects:

1. Condenser

The high-temperature and high-pressure Freon of the refrigeration system of the industrial refrigeration unit dedicated to the experimental instrument comes out of the compressor and enters the condenser, releasing a large amount of heat to the cooling medium and being liquefied by the cooling.

If the industrial refrigeration unit dedicated for laboratory instruments has been used for more than half a year, or the high and low pressure engines frequently fail, or the cooling capacity is reduced, please arrange a technician to clean the condenser. The fin condenser is generally cleaned with a high-pressure water gun. Be careful not to clean it sideways, which can easily cause the fin to fall over. Shell-and-tube condensers are generally immersed and circulated with descaling chemicals, and then the end cover is opened, and the pipes are cleaned one by one with a gun gun. Cleaning the condenser can significantly improve the refrigeration efficiency of the industrial refrigeration unit dedicated to laboratory instruments.

2. Compressor

Every time the compressor operating time of the industrial refrigeration unit dedicated to the experimental instrument exceeds one thousand hours, all details of the compression equipment should be checked. For example: whether the lubricating oil is normal; whether the running current of the compressor is normal; whether there is any abnormality when the compressor is running. Of course, the current refrigeration technology is quite mature, there are many sensors and protectors. When the unit alarms the fault, it should be repaired according to the fault location. When the compressor makes abnormal noise when it is running, it should be shut down for maintenance, mostly due to insufficient lubricant.

3. Refrigerant

The industrial refrigeration unit dedicated to experimental instruments is an indispensable equipment for industrial production now, and each unit is inseparable from the participation of refrigerant, so the lack of refrigerant will affect the normal operation of the machine and will appear The cooling capacity of the industrial refrigeration unit dedicated to the experimental instrument is insufficient, or the cooling temperature is very slow.

Routine maintenance cannot be ignored. Effective maintenance can keep the industrial refrigeration unit dedicated to laboratory instruments in an effective state of operation.

Verwandte Empfehlungen

-

-

Betriebsanleitung für den Verdampfer eines großen Industriekühlschranks

1162Im Betriebsprozess von Wuxi Guanya LNEYA großen industriellen Kühlschrank, aufgrund der großen Anzahl von Teilen und komplex, müssen wir den Betrieb der Komponenten in großen industriellen Kühlschränken zu verstehen. Der Verdampfer ist einer der wichtigsten K...

Details anzeigen -

Analyse der Gründe für die Nichtkühlung kryogener Kühlanlagen

1064Ultra-Niedrigtemperatur-Kälteanlagen werden hauptsächlich in der industriellen Kälteverarbeitung eingesetzt. Im Gegensatz zu einigen Herstellern von Ultra-Niedrigtemperatur-Kälteanlagen verwendet LNEYA Ultra-Niedrigtemperatur-Kälteanlagen umweltfreundliche...

Details anzeigen -

Price Analysis of High Low Temperature Test Chambers

1023As the saying goes, “ You get what you've paid. ” The price of the high low temperature test chamber is related to the quality of its configuration. The technology of Wuxi LNEYA itself is priceless. In the test chamber industry, the high low tempe...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant