Industry and introduction of low temperature chiller

In petroleum refining, petrochemical industry, organic synthesis, chemical products and other industrial production, refrigeration technology must be applied to control the reaction temperature during processes such as liquefaction, condensation, solidification, separation, refining, crystallization, concentration, and purification.

The chemical industry is mainly used for the cooling and cooling of chemical reaction kettles, and takes away the ordinary heat generated by chemical reactions in time to reach the purpose of cooling (cooling), in order to improve product quality. If the cold water (wind) provided by the refrigerator is used for cooling, not only the product quality can be greatly improved, but also the consumption efficiency can be improved. The pharmaceutical industry is mainly used to control the temperature and humidity of the workshop and to take out the heat of reaction during the process of consuming the drug substance.

Refrigerators in the industry are basically composed of components such as evaporators, single-stage compressors, oil separators, condensers, and liquid storage tanks. LNEYA’s freezer has exclusive technology, the temperature range is -5 ℃ ~ -150 ℃, which can meet different temperatures. This cooler uses international brand Carrier compressor, adopts automatic cascade refrigeration mode and mixed refrigerant, direct cooling ultra-low temperature freezer, single compressor automatic cascade refrigeration technology can freeze to minus 120 ° C in 3 minutes. Before delivery to customers, the production workshop provides machine installation and system testing. Users only need to complete the installation of refrigerant and cooling water.

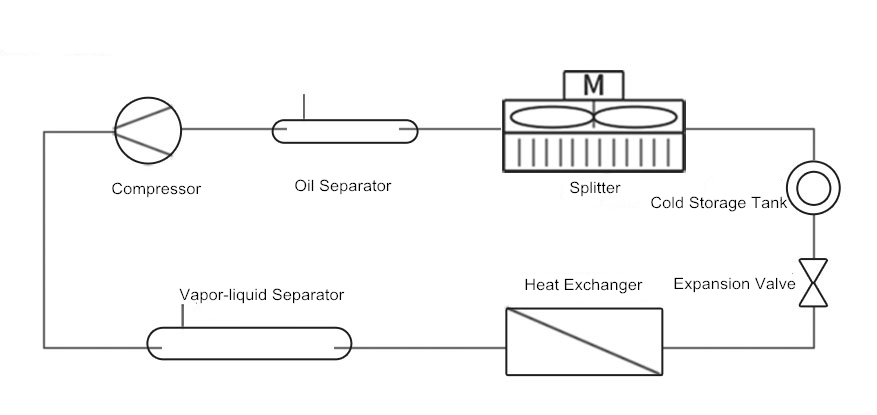

The working principle of LNEYA low temperature chiller is as follows:

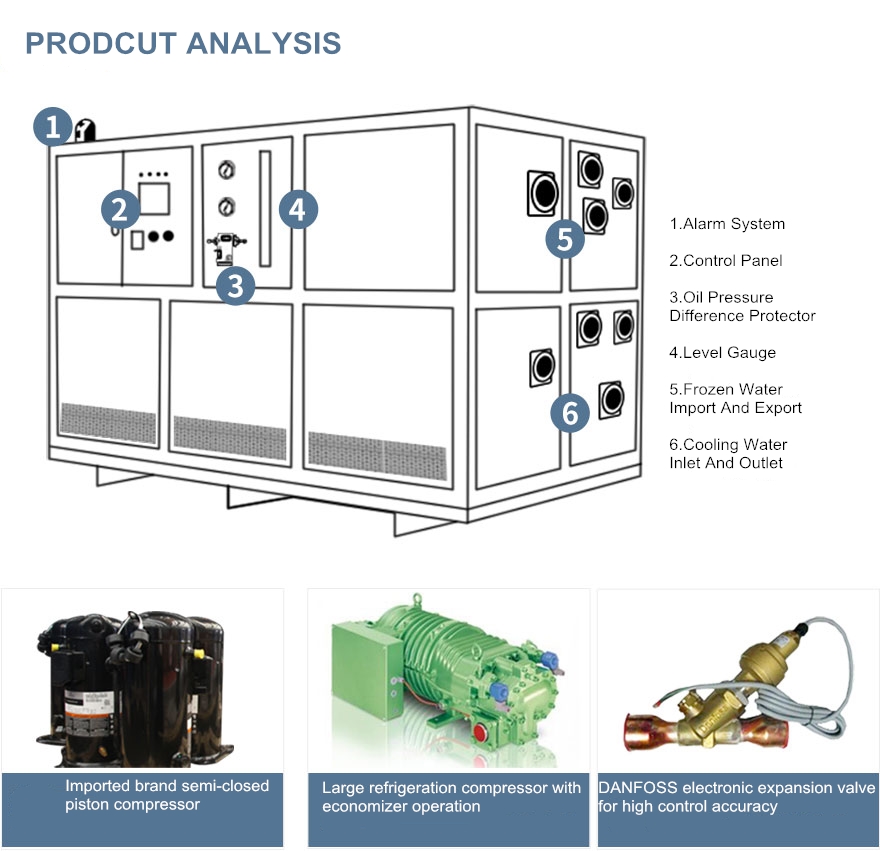

low temgperature chiller appearance:

Verwandte Empfehlungen

-

Organic waste gas treatment device noise description

1383With the increasingly stringent environmental requirements, various manufacturers have paid more and more attention to their own organic waste gas treatment. LNEYA organic waste gas treatment equipment specializes in the treatment of various organ...

Details anzeigen -

What is the principle of industrial air-cooled chillers

1568Many industrial productions are inseparablefrom the low-temperature production environment provided by the chiller andcannot obtain efficient production capacity. Therefore, industrial chillerequipment is a very important refrigeration equipmen...

Details anzeigen -

Ultra-high temperature material cold and hot impact box refrigeration oil

1181The ultra-high temperature material impact test chamber test device has too much frozen oil in the evaporator, which can also cause insufficient cooling and cause slow cooling. The oil stored in the evaporator of the ultra-high temperature materia...

Details anzeigen -

Recommendations for the use of integrated chip test equipment in the test process

1039From the perspective of the entire semiconductor industry, semiconductors can be divided into R & D, production, and application stages. At different stages, the role of testing is different. Control of test equipment, including test machines,...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant