Precautions for safe use of heat transfer oil temperature control equipment

With the extensive use of thermal oil temperature control equipment, the safe use of thermal oil temperature control equipment is a concern for users. For manufacturers, it is very important to share the precautions for the use of thermal oil temperature control equipment.

For users of thermal oil temperature control equipment, the fire protection of these electric heating equipment is very important. Firstly, analyze the cause of the general fire in the electric heating equipment. Place the electric heater that is energized near the flammable or inflammable material, and cause a fire under the high temperature baking for a long time. The electric heater is not equipped with a plug, and the electric wire head is directly inserted into the socket, so that a short circuit may occur and a fire may occur. The user of the heat-conducting oil temperature control device does not remove the plug of the electric heater when leaving, and the time is too long, causing the electric heater to overheat and igniting the adjacent combustible material to cause a fire. The heat-conducting oil temperature control equipment heating wire is used after repeated repairs, which may cause the line to be overloaded and cause a fire. It is worth noting that the heating wire of the heat-conducting oil temperature control device is made of nickel or chrome alloy. Since the power of the electric heater is relatively large, the user may accidentally ignore the safety, and the fire may occur at any time.

In order to prevent the heat conduction oil temperature control equipment from catching fire, the wire must be installed with a plug. The wire end should not be directly inserted into the socket. The temperature of the heat conduction oil temperature control equipment should be replaced in time. The electric heater without the fuse installed in the circuit should not be used. When the temperature control equipment of the heat transfer oil is used, it must be taken care of. When leaving, the plug should be unplugged. In the course of use, if there is a power outage, the plug should be pulled out in time, and should not be forgotten. For the heating wire that has been repaired many times, it is recommended not to use it, and a new heating wire should be replaced. Inflammable and explosive materials are strictly prohibited from drying with heat-conducting oil temperature control equipment. The electric oven should have a temperature-controlled device that prevents the temperature from being too high and prevents the baking time from being too long.

Users and friends, when using heat transfer oil temperature control equipment, can not place flammable materials near the heat transfer oil temperature control equipment, it is recommended to maintain a certain safe distance. (This article is from the source network, if there is any infringement, please contact Lneya to delete, thank you.)

Verwandte Empfehlungen

-

Why do special gases used in semiconductor manufacturing processes require chillers?

1365When using special gases in semiconductor manufacturing processes, a chiller is required, mainly due to the following reasons: 3. Process requirements: In semiconductor manufacturing processes such as chemical vapor deposition...

Details anzeigen -

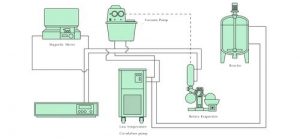

Low-temperature coolant circulation pump used with rotary evaporator

1906The chemical and pharmaceutical fields are the largest end consumer markets for cryogenic coolant circulation pumps. With the increasing demand for low-temperature coolant circulation pumps in this market, the application of cryogenic pumps in the...

Details anzeigen -

Regelverfahren für Halbleiter-Testkühler zur Erfüllung von Temperaturanforderungen

1748In der Biopharmazie ist eine hochpräzise Temperatur erforderlich, um die Aktivität von Enzymen und die Herstellung von Produkten zu steuern; in der chemischen Industrie sind bestimmte Temperaturen erforderlich, damit chemische Reaktionen stabil ablaufen; in der...

Details anzeigen -

Operation Instructions of Heating Cooling Circulator

1663Heating cooling circulator is a process that refrigerant transfers heat from low temperature state to high temperature state, so that its cooling can reach the state of low temperature environment, thus maintaining the low temperature state and re...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant