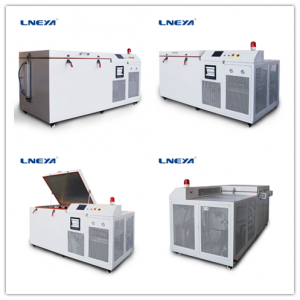

Kühl- und Heizungsthermostat für die Prüfung von elektronischen Bauteilen

If enterprises want the cooling and heating thermostats for electronic component testing to operate for a long time without any faults, they need to achieve the following points to maintain stable equipment performance.

1. Suitable working environment:

Provide a better operating environment for cooling and heating thermostats for electronic component testing. Keeping the environment clean and tidy can reduce the impact of various types of dust on the cooling and heating thermostats for electronic component testing, thereby improving its heat dissipation stability. Only by maintaining a good heat dissipation effect of the cooling and heating thermostat for electronic component testing can we improve cooling performance, reduce environmental temperature in a shorter period of time, and reduce energy consumption of equipment used by enterprises.

2. Maintain a low failure rate:

As long as meticulous maintenance and upkeep are carried out on a daily basis, the probability of failure of the cooling and heating thermostat for electronic component testing is very low. At the same time, it is necessary for operators to complete the opening and closing of the equipment according to the manufacturer’s required usage steps, in order to avoid incorrect operating behaviors that may affect the service life and even lead to various types of faults.

3. Timely repair in case of minor faults:

Small faults are inevitable in the cooling and heating thermostats used in electronic component testing. It is necessary for enterprises to promptly and effectively complete all maintenance processes to reduce the impact of small faults on the cooling and heating thermostats used in electronic component testing. Therefore, the operational stability must be within a high standard range.

4. The operation management of cooling and heating thermostats for electronic component testing is also crucial:

Mastering the scientific operating procedures, maintenance and repair methods of equipment, as well as the management of maintenance, renovation, and scrapping of refrigerators, can ensure that the cooling and heating thermostats used for electronic component testing are always in normal operation.

Verwandte Empfehlungen

-

Precautions for changing the refrigerating oil in the cooling system of the car charger

1247The cooling system of the car charger should pay attention to the condition of the refrigerating oil during the operation. After the compressor is started, carefully observe the changes in the oil temperature and oil pressure. If the oil changes c...

Details anzeigen -

What are the reasons for the power consumption of large-size refrigeration units?

1513During the operation of large-size refrigeration units, the cooling capacity and working conditions are the main issues of power consumption, but in order to avoid some unnecessary power consumption, we need to understand clearly. When the scale o...

Details anzeigen -

Instructions to Use Industrial Cryogenic Refrigerator

1775Industrial refrigerators are one of the cold water machines. It is classified according to the cooling mode of the cold water machine itself. It is divided into air cooling type refrigerators and water cooled refrigerators. Structural features: a ...

Details anzeigen -

Selection of Temperature Control System for Laboratory Resin Reaction Kettle

15691. Choose from the quality of the laboratory resin reactor temperature control system: can affect the quality of the laboratory resin reactor temperature control system, may be the use of accessories. There are some small factories on the market t...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant