Precautions for changing the refrigerating oil in the cooling system of the car charger

The cooling system of the car charger should pay attention to the condition of the refrigerating oil during the operation. After the compressor is started, carefully observe the changes in the oil temperature and oil pressure. If the oil changes color, the oil must be changed until the system is clean. Piston refrigerators that are normally put into production and operation must undergo a limited period of maintenance after long-term operation and replace the refrigerating oil.

1. Refrigerating oil replacement operating procedures

1. Close the high-pressure exhaust and low-pressure suction shut-off valves, and use the process valve needle on the compressor to release the refrigerant inside the compressor to make the crankcase of the compressor communicate with the atmosphere.

2. Unscrew the oil drain plug at the bottom of the crankcase, drain the refrigerant oil in the crankcase, and remove the filter for cleaning.

3. Nitrogen can be blown in from the low-pressure inflation valve needle, and the oil drain port can be blocked by hand to increase the pressure in the body, and further remove the residual oil in the body, dry the cleaned filter into the body and tighten the oil drain plug .

2. Refrigerating oil injection

Plan 1: Unscrew the process port plunger on the side of the compressor crankcase, use it as a filling port to pour the refrigerated oil into the crankcase through a suitable tool;

Option 2: (for piston machine) connect the low-pressure pipe of the fluorine-filling meter to the low-pressure process valve needle of the cavity of the piston-type refrigerator, use a vacuum pump to pump the crankcase to negative pressure, and remove the other fluorine-filling pipe separately, one end Insert it into the container containing the refrigerated oil, and connect the other end to the valve needle of the low-pressure suction end of the oil pump, and suck the refrigerated oil into the crankcase by using the negative pressure in the crankcase.

Summary of considerations:

1. You can add a little less when changing the oil, and generally add it to the lower limit of the sight glass.

2. After the refrigerating oil filling is completed, tighten the process plunger or remove the fluorine filling tube, and connect the fluorine pressure gauge to vacuum the compressor.

3. After the vacuum is completed, open the compressor high and low pressure stop valve to check whether there is refrigerant leakage.

4. After turning on the cooling system, check the compressor lubrication and the oil level of the oil glass immediately. If the oil level is lower than the normal range, add refrigerating oil. If necessary, connect an oil pressure gauge to the needle valve of the oil pump to check the oil pressure.

5. The suction side pressure of the oil pump of the semi-hermetic piston compressor should be basically the same as the low pressure suction pressure, and the allowable value of the oil pressure difference.

Matters needing attention:

The refrigerated oil in the cooling system of the car charger is hygroscopic, and the moisture in the oil chemically reacts with the oil. It requires special care when working to minimize the air entering the system and the oil storage container; the refrigerating oil should not be added in excess. If the refrigerating oil is added in excess, There is a danger of liquid shock when the cooling system is reopened.

Verwandte Empfehlungen

-

Solution to oil spill of reactor cooling and heating circulator

1462When we use some reactor cooling and heating circulators, we will find that the system pressure fluctuates up and down as the temperature rises, and the oil tank is overflowing. So what are the reasons for these conditions in the cooling and heat...

Details anzeigen -

Kühlungs-Simulationssystem für die Prüfung der extremen Leistung von Batteriepacks

1683Mit der Entwicklung der Technologie werden reine Elektrofahrzeuge immer häufiger, aber reine Elektrofahrzeuge sind schwierig, eine bessere Lösung in Bezug auf Reichweite, Ladegeschwindigkeit und Umweltverschmutzung nach Batterieabfall zu bekommen. Dies macht...

Details anzeigen -

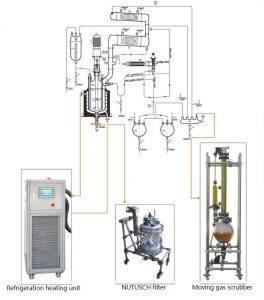

Hochwertige professionelle Ausrüstung hilft dem Labor, unendlich viele Ergebnisse zu erzielen

2826In recent years, China's economy has continued to grow. Under the development opportunity of professional high and low temperature integrated machines, laboratory scientific and technological achievements are also in sustainable development. LNEYA...

Details anzeigen -

Operating Principle of LNEYA Industrial Air Cooled Chillers

2074Industrial Air Cooled Chillers is a heatexchanger which USES air to cool the hot fluid. The hot fluid in the tube isheated through the exchange of heat between the tube wall, the fin and theoutside air, which is usually supplied by the ventilat...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant