Design und Testtechnologie von Hochtemperatur-Umweltkammern Vertrieb

1. Temperature selection

(1) The climatic zones of the region; Whether the product is exposed to the solar radiation environment near the heating device; Surrounding air, solar radiation and ways of heat transfer from heating devices to products; The actual technical state of the product (open or shaded).

(2)Use similar product temperature. Similar products refer to those with similar USES, performance and installation locations, such as upgrading products

2. The conditions of environmental chamber sales

(1) High-temperature storage

Thermostatic storage: after the sample reaches temperature stability (the temperature of internal components, components, modules, components, etc., also reaches stability) in the high-temperature environment, it can be maintained for at least 2 hours, and the longest can be 48 hours. If the storage time is over 48 hours, the temperature stability time will be included.

Cyclic storage: at least 7 cycles (24h for one cycle). If the key material or high temperature sensitive material is affected by high temperature environment, the cycle number should be increased appropriately.

(2) Hot operation in environmental chamber sales

Thermostatic work: after samples reached the stable in high temperature working environment(judgment methods: the differences of the internal heat of samples of the largest feature or key components should be less than 2 ℃ per hour , If the temperature of the internal element (part) cannot be measured, the temperature time shall be determined according to the thermal analysis to ensure that the temperature of the whole sample is stable)keep it at least 2 h, and then let the sample work, and make it on the specified working temperature to achieve stability, began to test the functionality and performance. After the test is completed, the sample will stop working and the air temperature in the box will be adjusted to the standard atmospheric conditions. After reaching the stability under the standard atmospheric conditions, the overall appearance, function and performance will be tested.

3. Temperature monitoring in environmental chambers

When monitoring the test temperature, the position of the temperature sensor should ensure that the influence of thermal diffusion is negligible, and pay attention to avoid the influence of thermal radiation.

Verwandte Empfehlungen

-

Environmental Conditions for Installation of Air Cooled Chillers

1635As we all know, the installation of most machines needs to match the environment and conditions. Of course, our industrial air-cooled chillers are no exception. If the air-cooled chiller is not installed for the first time, it will bring a lot of ...

Details anzeigen -

How to judge the operating status of the chemical and pharmaceutical constant temperature control sy

1521Nowadays, many pharmaceutical and chemical industries use LNEYA's constant temperature control system. How to judge its operation status during operation? There should be no noise in the cylinder of the chemical and pharmaceutical thermostatic con...

Details anzeigen -

Vorkehrungen für die Installation von Reaktorkühl- und Heizkreislaufgeräten

2208Einbau der Reaktortemperiereinheit

Details anzeigen -

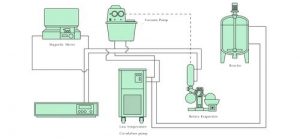

Low-temperature coolant circulation pump used with rotary evaporator

1906The chemical and pharmaceutical fields are the largest end consumer markets for cryogenic coolant circulation pumps. With the increasing demand for low-temperature coolant circulation pumps in this market, the application of cryogenic pumps in the...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant