Umwelttechnische Beschreibung eines Kondensators für große industrielle Gefriergeräte

In der industriellen Kälteverarbeitung gehören große industrielle Gefrierschränke zu den am häufigsten verwendeten Geräten. Dabei ist der Kondensator eine der wichtigsten Komponenten, und seine Leistung ist sehr wichtig. Daher muss jeder bei der Auswahl noch verstehen,...

When the large industrial freezer system is in operation, the reason for the change of the condensing temperature is the change of the temperature of the cooling medium. The temperature of the condensing depends on the heat transfer area of the condenser, the temperature of the cooling medium, the purity and sufficient amount of the refrigerant, and the compressor. Exhaust temperature and displacement, etc. In normal operation, the condensing temperature and pressure are basically stable, and the space can be adjusted. It is often caused by a system failure (such as sudden water cut or improper number of condensers), causing the machine to malfunction. In operation, it should be checked frequently and found. When you have a problem, you should find the cause and solve it in time to avoid the more serious the damage to the machine.

The temperature environment of different types of condensers for large industrial freezers is different. The condensation temperature of vertical, horizontal shell and shower condensers is 4-6 °C higher than that of cooling water, and the condensation of evaporative condensers The temperature is 5 to 10 ° C higher than the wet bulb temperature of the outdoor air in summer, and the temperature of the air-cooled condenser is 8 to 12 ° C higher than the air temperature.

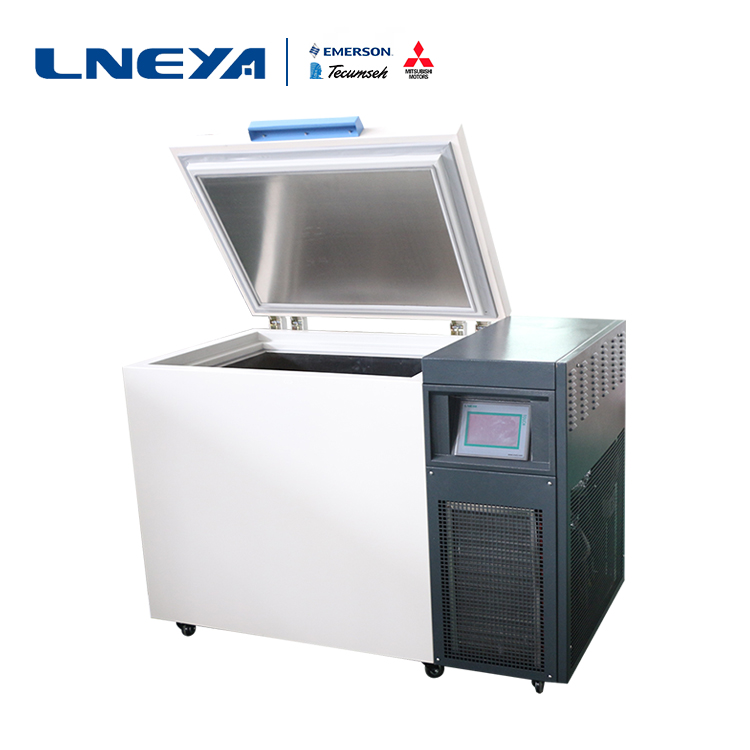

In Wuxi Guanya LNEYA large industrial freezer refrigeration system, the external heat release of the refrigerant is the normal operation of the condenser. After the high temperature gas discharged from the compressor enters the condenser, the heat is transferred to the medium (water or air), the refrigerant. The steam is cooled and condensed into a liquid, and the liquefied refrigerant enters the evaporator through throttling, thereby achieving the purpose of repeated cycle refrigeration of the industrial explosion-proof large-scale industrial refrigerator. If the accumulator and the condenser are installed in the large industrial freezer at the same height, the outlet pipe at the bottom of the condenser needs to be bent upward to the upper part of the accumulator. This may cause the liquid seal to appear in the pipe. The exhaust function of the compressor, once there is a certain liquid level in the reservoir, will reduce the condensation area of the condenser, increase the condensation temperature and pressure, increase the power consumption, and cause the operating conditions of the freezer refrigeration system to be poor.

The condenser and the accumulator in the large industrial freezer are one of the most important accessories. The above accessories knowledge hopes that everyone can understand clearly.

Verwandte Empfehlungen

-

What are the effects of the oil separator on the equipment analyzed by the chiller manufacturer

1339Oil separators use more accessories in thechiller refrigeration system. So as users, we need to understand where the mainimpact is in order to better use the equipment.In the configuration of the chiller, theposition of the oil separator is aft...

Details anzeigen -

kryogene Kältemaschinen für Prozesse der Drogenfluss-Chemie

1346Niedertemperaturkühler, die in der Arzneimittelfluss-Chemie (kontinuierliche Herstellungsverfahren) eingesetzt werden, sind eines der wichtigsten Geräte, um sicherzustellen, dass die Reaktionen unter präzisen Temperaturbedingungen ablaufen. Die Fließchemie ist eine kontinuierliche Fertigungstechnik...

Details anzeigen -

Kühleffekt einer wassergekühlten Kältemaschine bei -15℃

1378Die Hauptbestandteile von wassergekühlten Kaltwassersätzen sind: Kompressoren, elektrische Komponenten, Wasserpumpen, Verdampfer, Verflüssiger, Hoch-/Niederdruckregler, Hoch-/Niederdruckmanometer, LCD-Thermostate, Expansionsventile, Frostschutzschalter, Handventile...

Details anzeigen -

The savior of the cannabis extraction industry cannabis oil chiller | CBD chiller

1627The hemp, cannabis, and CBD/THC industry is taking off. Efficient and effective equipment is required to maintain the quality of CBD and THC oils. Oils can go rancid and break down without proper preservation. Re-outfitting a refrigerator or alcoh...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant