Wie kann man den Fehler des Druckreglers des Tiefkühlschranks beheben?

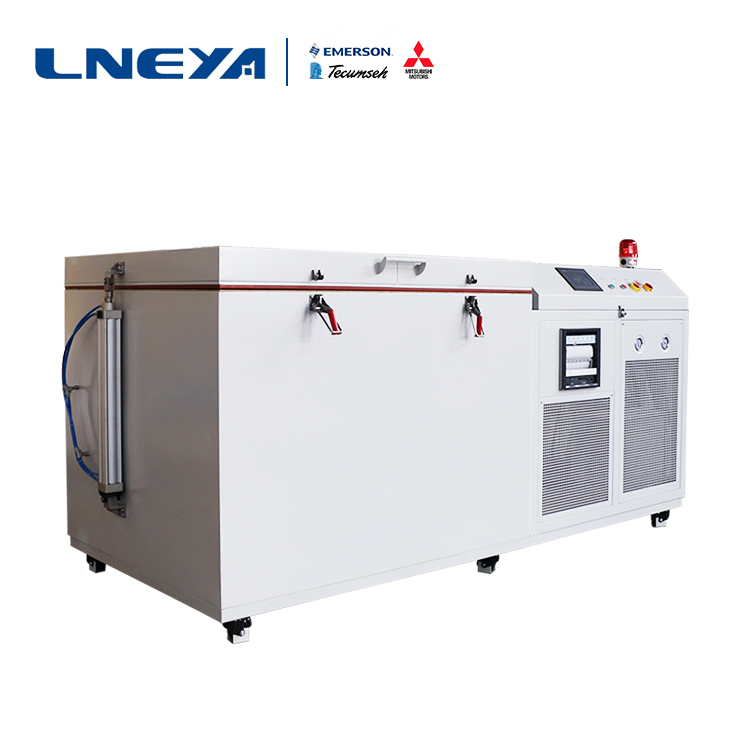

If the industrial ultra-low temperature refrigerator encounters a controller-related failure during operation, if it is not resolved in time, the pressure controller may be unavailable.

The pressure controller plays a very important role in the ultra-low temperature refrigerator group. Because of the pressure exerted between each accessory under the high-efficiency working state, the range is different.

In order to reduce the impact of pressure on the ultra-low temperature refrigerator group, the company should regularly check the pressure controller carefully. Only careful inspection can ensure that the equipment operates within a stable and safe pressure range, and the pressure is stable. The problem will be reduced accordingly.

So, where is the pressure controller? The pressure control unit is installed in different positions and there will be different pressures. The range of settings is different, and the effect on the ultra-low temperature refrigerator group is also different. The principle of high pressure and low pressure is different, and the scope of protection for intelligent ultra-low temperature refrigerators is also different. In actual use, there may be excessive pressure, or the pressure is too small. Naturally, there are some internal causes. If you let it develop, it will have a bad influence on the machinery. At this time, the equipment will be It will be a self-protection method by powering off. By reducing this gap, you can try to make the equipment less problematic and the life will increase accordingly. Therefore, it needs to operate within a very safe pressure range. The technology will run steadily.

For ultra-low temperature refrigerator users, the company should ask technicians to train these personnel to let them know the maintenance expertise, what should be checked, and which conditions should be taken care of.

If the relevant configuration of the ultra-low temperature refrigerator is relatively high, the pressure controller failure is relatively small, so it is recommended to choose a reliable manufacturer to purchase.

Verwandte Empfehlungen

-

Explosionsgeschützte heiße und kalte Maschine Winterwartungsanleitung

1938Wenn die explosionsgeschützte Kalt- und Warmwassermaschine am Ende des Tages oder bei Nichtbenutzung durch den Bereitschaftsdienst benutzt wird, muss die Kühlwasserleitung abgetrennt, das restliche Kühlwasser in der Leitung gereinigt und...

Details anzeigen -

Chip test dedicated TES-5 series preparation instructions

1546The TES-5 series for chip testing is used for electronic component testing. How to accurately detect the chip is very important. So, how much do you know about the test preparation for the TES-5 series for chip testing? Before starting the TES-5 s...

Details anzeigen -

TCU temperature control model selection and technical parameter description

2153TCU temperature control is also a two-cycle unit single-fluid temperature control system. When selecting the model, it is very important for the whole temperature control reaction. Only the appropriate reaction system is used to exotherm and absor...

Details anzeigen -

Thermische Reaktorkontrolleinheit und Lösungen für Chemikalien

2153Temperaturkontrolle ist ein Prozess, bei dem die Temperatur einer Substanz oder eine Temperaturänderung gemessen oder anderweitig erfasst wird und die Übertragung von Wärmeenergie in oder aus dem Raum oder der Substanz eingestellt wird, um die gewünschte Temperatur zu erreichen...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant