Thermische Reaktorkontrolleinheit und Lösungen für Chemikalien

Temperaturkontrolle ist ein Prozess, bei dem die Temperatur einer Substanz oder eine Temperaturänderung gemessen oder anderweitig erfasst wird und die Übertragung von Wärmeenergie in oder aus dem Raum oder der Substanz eingestellt wird, um die gewünschte Temperatur zu erreichen...

When dealing with pharmaceutical production, maintaining accurate temperature control is critical. Starting with research throughout production, precise temperature control is required at every stage of the process. We fully understand the importance of process cooling, and simple temperature fluctuations (positive and negative) can ruin research or production.

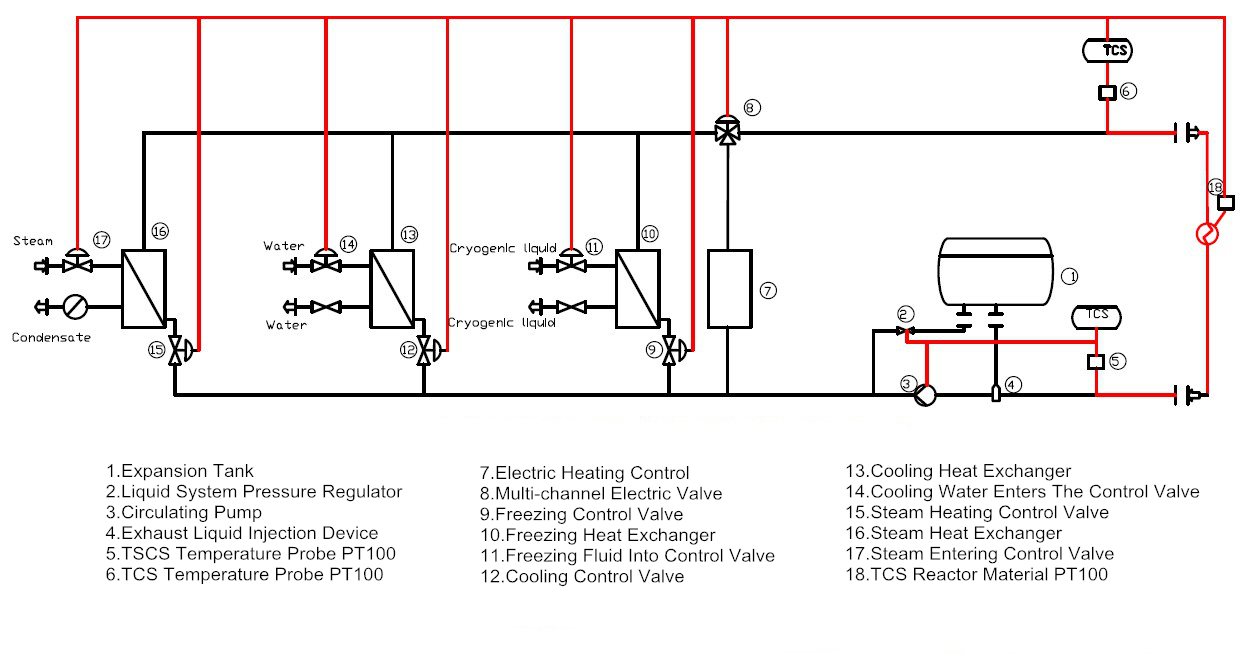

Our TCU can meet all your heating, cooling and temperature control needs for your chemical or pharmaceutical reactor. The LNEYA-TCU temperature control system can utilize existing thermal energy (such as steam, cooling water and ultra-low temperature liquids-the “primary system”) infrastructure integration to achieve dynamic temperature control of the equipment temperature in a single fluid system or a secondary circuit. This only completes the flow of a heat transfer liquid into the jacket of the reaction vessel (rather than directly into the steam, cooling water or cryogenic liquid), and the temperature of the entire reaction process is controlled by calculation.

From -120°C for cryogenic pharmaceutical applications to 300°C for chemical applications, the maximum temperature can be set according to the supplier’s heating or cooling source. The maximum temperature range can be set using a glycol water formula. Through three-point sampling (material temperature point, outlet temperature of temperature control system, inlet temperature of temperature control system), and our own model-free self-building algorithm and general anti-lag cascade algorithm, the problem of large drug delays is solved. Chemical temperature control . Our SR series and ZLF series are completely suitable for low temperature reaction, synthesis, separation process, pilot plant, reactor system, autoclave, combinatorial chemistry, etc.

This will increase product profitability and reactor utilization, and reduce energy and plant operating costs. Our TCU is fully automated and easy to operate. The temperature control accuracy of the product is ± 0.5 ° C, and the cooling power can be provided from 0.5 kW to 1200 kW.

The picture below shows the TCU thermal control unit customized by domestic customers

Verwandte Empfehlungen

-

Refrigerating Output of Low Temperature Cooling Circulator

1393The refrigerating output of low temperature cooling circulator varies with different working conditions. So, when the process calculation is carried out at the beginning, it is necessary to set an allowance for the refrigerating output of the heat...

Details anzeigen -

The benefits of choosing a cryostat

2146The temperature of the effluent of the cryogenic refrigerator is very low, so the carrier medium can not be used for water (the water will freeze when it reaches 0 ° C). At this time, it is necessary to use a brine solution or a glycol solution, a...

Details anzeigen -

Constant temperature circulation device can help chip to complete reliability test

1515As the country vigorously develops domestic chips, chip manufacturing is entering the fast lane. After the chip is manufactured, there is a very critical link, which is the reliability test, and the constant temperature circulation device can quic...

Details anzeigen -

Abschaltverfahren bei Ausfall der Hochpräzisions-Hoch-Tieftemperatur-Umwälzpumpe

1810Der hochpräzise Hoch-Niedertemperatur-Umwälzthermostat ist eines der Geräte, die in der pharmazeutischen und chemischen Industrie zur Unterstützung verschiedener Reaktoren eingesetzt werden. Wenn es während des Betriebs zu einem abnormalen Stromausfall kommt, sollten die Benutzer auf den Betrieb...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant