Specific conditions of high and low temperature test of EV (electric vehicle) battery

There are mainly 2 types of vehicles:

1. Battery for pure electric vehicle

2. Fuel cell, dedicated to fuel cell electric vehicles

Thermal test: This test is performed to characterize the reaction of cells to the high-temperature environment.

a) Adjust the SOC of battery to 100% of BEV application and 80% of HEV application.

b) Batteries stabilized at room temperature shall be placed in a gravity or circulating air convection oven. The oven temperature shall be raised to 130 ℃ ± 2K at the speed of 5K/min. The battery shall be held at this temperature for 30 minutes before stopping the test.

Temperatur-Zyklustest:

This test is conducted to characterize the thermal durability of the battery by alternately exposing it to low and high temperatures to cause expansion and contraction of the battery components.

a) Adjust the SOC of battery to 100% of BEV application and 80% of HEV application.

b) Conduct temperature cycling according to ISO 16750-4. As shown in Table 4, the ultra-low operating temperature shall be – 40 ℃ or Tmin specified by the battery manufacturer, and the maximum operating temperature shall be 85 ℃ or Tmax specified by the battery manufacturer. Perform 30 test cycles as specified.

The battery shall be heated in a gravity convection or circulating air oven with an initial temperature of 20 ± 5 ° C (68 ± 9 ° F). The temperature of the oven is raised to 130 ± 2 ℃ (266 ± 3.6 ℉) at the rate of 5 ± 2 ℃ (9 ± 3.6 ℉) per minute and maintained for 10 minutes. The sample shall be returned to room temperature (20 ± 5 ℃) and then checked. For batteries with a set temperature higher than 100 ℃ (212 ℉), the regulating temperature shall be increased from 130 ± 2 ℃ (266 ± 3.6 ℉) to 30 ± 2 ℃ (86 ± 3.6 ℉) from the manufacturer’s maximum specified temperature. For lithium metal chemical battery, the regulating temperature shall be increased to 170 ± 2 ℃ (338 ± 3.6 ℉) at most.

The above contents are excerpts from the network. Please contact us if you have any questions.

Verwandte Empfehlungen

-

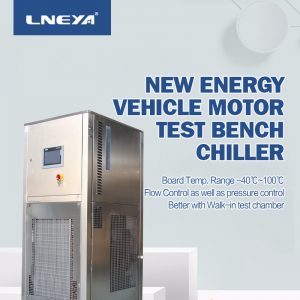

Umfassendes Testsystem für Automobilmotoren mit neuer Energie

1784When the LNEYA new energy vehicle motor integrated test system is running, the control panel settings are required. At the time of setting, if the user does not know how to use it, you can check the manual for use. The indicator of the new energy ...

Details anzeigen -

Burning machine phenomenon in small high and low temperature integrated machine

1414The small high-low temperature integrated machine is used for the temperature control of the connected reactor in the pharmaceutical, chemical and other industries. Once the burning phenomenon occurs during operation, we need to pay special attent...

Details anzeigen -

483Meet Your Dream Equipment für die CBD-Destillat-Extraktion

1821Wenn Sie eine Anlage zur Destillation von CBD benötigen, müssen Sie Ihre Wahl genau prüfen, da die Geräte in ihren Eigenschaften und ihrem Design variieren können. Wenn Sie Geräte zur Herstellung von CBD-Destillaten verwenden, sollten Sie ein System von einem Hersteller wählen, der...

Details anzeigen -

Hybrid car battery test equipment cooling capacity description

1590Due to insufficient insulation thickness of the hybrid vehicle battery test equipment and pipeline or damage to the insulation layer, the loss of cooling capacity is increased, which affects the cooling effect. In the operation of the hybrid vehic...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant