What are the refrigerants for the 120-degree ultra-low temperature freezer?

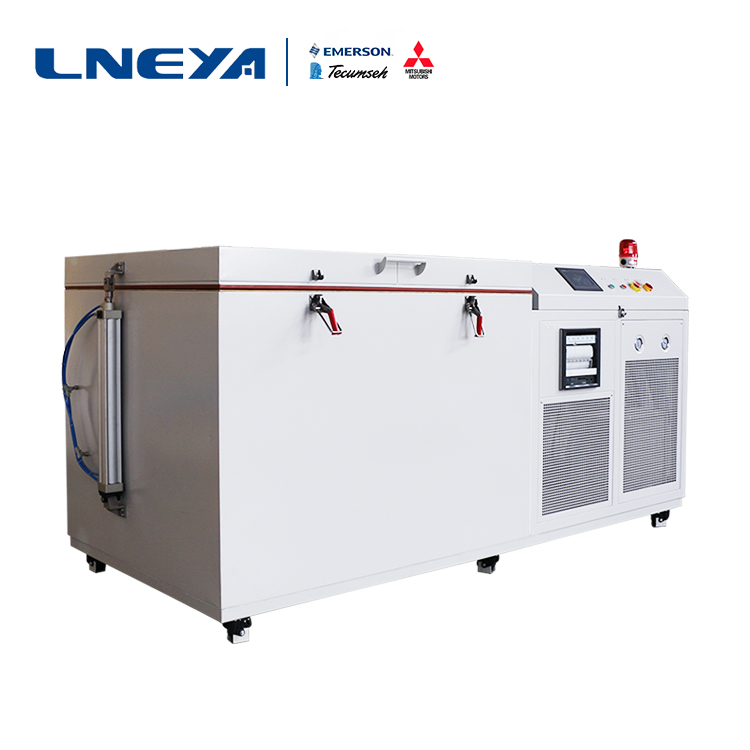

The refrigerants of different ultra-low temperature freezer manufacturers are different. The refrigerants commonly used in LNEYA refrigeration equipment are R404, R22, etc. So, what is the difference between the two-120-degree ultra-low temperature freezer refrigerant?

Since the saturation pressure of R404A is higher than R22, the design pressure of the pressure vessel in the system should be changed to ensure safety. Such as liquid storage and gas-liquid separators. At the same time, the set values of the safety valve and fusible plug installed on the system components will also change. Since the gas density of R404A is about 50% larger than that of R22 under the same exhaust gas amount, the pipe diameter selected is larger than R22 when piping design using R404A refrigerant.

For the same compressor, the current of the R40A in the -120 degree ultra-low temperature freezer is greater than R22, so the wire diameter of the AC contactor, thermal relay and cable of the compressor should be adjusted. In terms of system protection, the high pressure switch setting is adjusted from the original 2.45 MPa to 2.7 MPa. The exhaust pressure of the R404A refrigerant is about 1.2 times that of R22, and the mass flow rate is about 1.5 times that of R22. The exhaust flow rate increases and the resistance increases. In general, the heat transfer capacity of the condenser is increased by 20% to 30% compared to R22.

The saturation pressure of R404A and R22 is different at the same temperature, so the action mechanism of the -120 degree ultra-low temperature freezer R404A thermal expansion valve is different from that of R22. At the same time, because the R404A refrigerant and lubricating oil have different compatibility with the sealing material, the expansion valve sealing material should also be changed accordingly. Therefore, the R404A special expansion valve should be selected in the selection of the thermal expansion valve. Since the saturation pressure of 404A is different from that of R22, the air tightness test pressure is greater than R22. At the same time, the vacuum degree of the system is higher than R22, and the water content is lower than R22. The refrigerant should be charged in liquid form during charging to prevent changes in the R404A configuration.

The refrigerant R404A used in the 120 degree ultra-low temperature freezer is a non-azeotropic mixture. The concentration of the non-azeotropic mixture changes with temperature and pressure, which brings certain difficulties to the production, commissioning and maintenance of the refrigeration system. The heat transfer performance of the system will also have a certain impact, especially when the refrigerant leaks, the system refrigerant needs to be completely drained and replaced, so as to ensure the proportion of each mixed component, and also achieve the design cooling effect, otherwise it will get worse. .

The refrigerant of the -120 degree ultra-low temperature freezer should be selected according to the corresponding equipment. LNEYA selects the corresponding environmentally friendly refrigerant refrigerant, which is more in line with the development of the environmental protection theme of the contemporary era.

Verwandte Empfehlungen

-

Kühler für 200L Destillationskessel

770Die Kältemaschine für 200L Destillationskessel muss zwei Hauptfunktionen gleichzeitig erfüllen: Eine ist es, Methanoldampf zu kondensieren, und die andere ist es, das Material während des Reaktionsprozesses zu kühlen. ...

Details anzeigen -

Refrigeration heating circulator list resonance fault description

1184Refrigeration heating circulator leaderboard works: When the temperature of the reactor, reactor, rotary evaporator, extraction equipment, etc. of the refrigeration heating circulator needs to be rapidly increased or lowered, the equipment can qui...

Details anzeigen -

How to maintain the high and low temperature cooling constant temperature system?

922The high and low temperature cooling constant temperature system performs refrigeration and heating operation in the pharmaceutical and chemical industry. It follows the rules of operation and meticulous requirements to continuously improve its qu...

Details anzeigen -

Working principle of refrigeration and heating thermostat for chemical industry

984In the selection process of the special refrigeration and heating thermostat for chemical industry, the heating power and the pressure and flow rate of the heat transfer medium are also factors to be considered. Different raw materials have differ...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant