Description of LNEYA industrial ultra-low temperature freezer

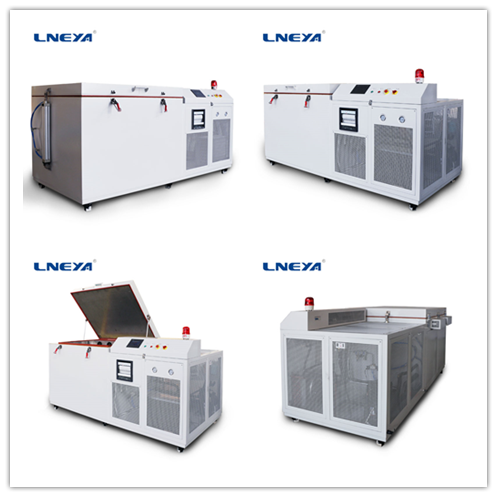

LNEYA industrial ultra-low temperature freezer is mainly used in industrial cold treatment to precipitate uniform, fine and dispersed carbides on the metal structure matrix. The appearance of such a carbide will bring about a significant increase in the wear resistance and friction properties of the metal, and the hardness will also increase, and will directly increase the life of the wear member. The ideal product to replace liquid nitrogen.

It can also be used for cold shrinkage of copper sleeves, bearings, etc., and is widely used in precision mechanical assembly. It is used in large equipment (automotive, large engineering machinery, aircraft parts, aerospace equipment parts, military equipment parts, ultra-low temperature test. It can be used for touch screen, display freeze degumming, disassembly.

Different manufacturers have different needs, so most of the cold processing equipment is made according to the requirements. Please provide the following indicators when ordering:

1 maximum load;

2 liner size: length, width, height;

3 Full load cooling to the target value time.

LNEYA industrial ultra-low temperature freezer uses nickel-chromium alloy electric heating heater, the controller itself has 2 protection, plus independent temperature limiter protection. Cooling of the equipment: (25 ° ambient temperature, under no-load conditions, from 0 degrees to -110 degrees for about 1.5 hours); (25 ° ambient temperature, under no-load conditions, from 0 degrees to -140 degrees About 2 hours); the device will have a slightly different cooling rate due to changes in ambient temperature.

The control mode of the device is ASET multi-function controller; 7-inch color touch screen, display setting temperature, measuring temperature and so on. The temperature curve records the temperature, and the U disk data is exported. The format is excel table and the fault record. The circulating air inside the cabinet: 2100m3/h; 2750m3/h; 4500m3/h….. When the door is opened, the internal circulation fan is automatically turned off, and the door opening state is displayed on the touch screen screen.

Compressors for all temperature ranges are international brands: Emerson Copeland compressors, which use single-compressor automatic cascade refrigeration technology.

Verwandte Empfehlungen

-

How to choose the accessory pump in the new energy vehicle battery test?

939New energy vehicle battery testing plays a more important role in the development of new energy vehicles. In the operation process, the pump is the key supporting equipment in the LNEYA test equipment, which is also concerned by people. So how to ...

Details anzeigen -

What are the reasons for the power consumption of large-size refrigeration units?

944During the operation of large-size refrigeration units, the cooling capacity and working conditions are the main issues of power consumption, but in order to avoid some unnecessary power consumption, we need to understand clearly. When the scale o...

Details anzeigen -

Umfassendes Testsystem für Automobilmotoren mit neuer Energie

1127When the LNEYA new energy vehicle motor integrated test system is running, the control panel settings are required. At the time of setting, if the user does not know how to use it, you can check the manual for use. The indicator of the new energy ...

Details anzeigen -

12hp freezer heat transfer oil selection instructions

1152When choosing a 12hp freezer, users need to pay attention to the choice of heat transfer oil. For LNEYA, suitable heat transfer oil is very important. What should you pay attention to when choosing heat transfer oil? The 12hp freezer adopts a full...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant