Which Type of Chiller Can Be Chosen for Cooling XRD?

The advantages of collecting single crystal X-ray diffraction data at low temperatures have long been recognized by the scientific community. The use of cryogenics has increased substantially in recent years with the availability of effective and reliable equipment and publications.

During the working status, X-ray tube generates a large amount of heat and needs to be cooled and protected by a cooling circulating water chiller. Without a chiller, the tube would overheat, leading to a multitude of issues including, eventually, tube failure . Usually requiring a low heat load of 5-8KW, cooling systems must provide precise temperature control for X-ray detectors to ensure maximum tube protection and longevity.

LNEYA FL series cooling system is environmentally friendly and suitable for advanced laboratory equipment. It is your best partner when looking for laboratory equipment. RG chiller and X-ray diffractometer (XRD), X-ray fluorescence spectrometer (XRFS), large field emission electron microscope, plasma etching machine, vacuum coating equipment, ion coating equipment, vacuum furnace, industrial furnace and other high-heat generating equipment Perfect match for industrial equipment. In addition, the RG series can also be used as a central chiller to meet the requirements of multiple instruments at the same time.

Featuring a closed cooler loop, it allows continuous, uninterrupted research and production at temperatures from -25 to 40°C. It is suitable for applications where reliable and rapid removal of operating heat is required in chemical production processes or where operating heat is removed from technical systems in harsh, continuously used environments. Unlike tap water cooling, this cooling circulator provides a constant temperature regardless of the time of year and pressure fluctuations. An independent cooling water system replaces the central cooling water supply system and avoids the leakage of environmentally harmful substances. Conserving water also protects the environment and significantly reduces operating costs. Applications include rotary evaporators and Soxhlet systems, analytical equipment such as electron microscopes, X-ray units, refractometers, distillation systems, X-ray control systems such as in airports and semiconductor systems, cooling trap control such as in gas drying, and Central cooling water supply completes the laboratory to replace mains water cooling.

Recommend Product

Laden...

已经是到最后一篇内容了!

Anwendungen

Verwandte Empfehlungen

-

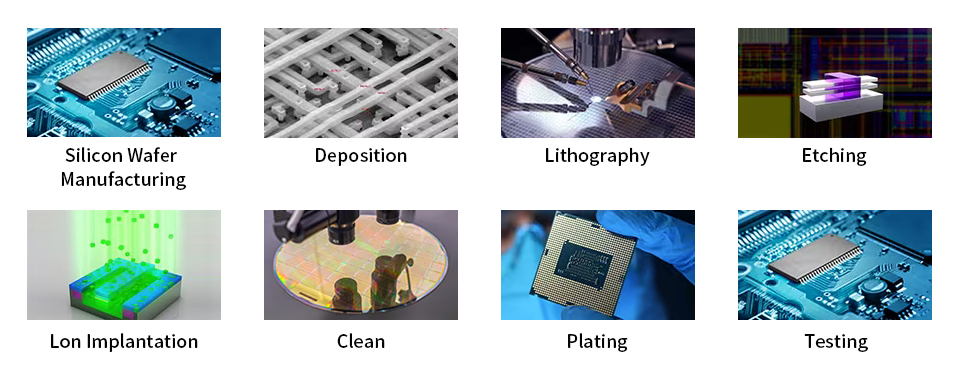

What type of chiller is needed for low-temperature etching?

933The low-temperature etching process usually requires extremely high precision temperature control and strong cooling ability to maintain stable operation of the etching equipment at extremely low temperatures, in order to achieve finer etchi...

Details anzeigen -

Maintenance principle of fluorinated liquid TCU temperature control system

941Fluorinated liquid TCU temperature control system should be placed in a ventilated, dry and clean place; (2) The distance between the fluorinated liquid TCU temperature control system and the partition is greater than 1m; (3) The lo...

Details anzeigen -

Summary of Maintenance Items of Glycol Chiller

1100During the daily operation of glycol chiller, if the maintenance is not in place, the cooling effect of glycol chiller will be reduced. Therefore, in order to improve the operation efficiency of glycol chiller, we suggest that you should carry out...

Details anzeigen -

Wie funktionieren CVD- und PVD-Kühler für Halbleiter?

1039The working principle of the chillers used in semiconductor chemical vapor deposition (CVD) and physical vapor deposition (PVD) processes is mainly to remove the heat generated during the process by circulating cooling water or special coola...

Details anzeigen -

Verfahren zum Einfrieren der rotierenden Welle bei der Montage von Automobilmotoren mit neuer Energie

1226Mit der allmählichen Ausweitung des Marktes für neue Energiefahrzeuge ist auch die Industrie für die Herstellung neuer Energiemotoren gewachsen. Dann, für den Motor Hersteller, der Rotor in den Kern-Prozess während der Motor-Montage-Prozess ist besonders wichtig...

Details anzeigen

LNEYA Industriekühler Hersteller Lieferant

LNEYA Industriekühler Hersteller Lieferant